Your portable solution for 3D scanning and easy inspection

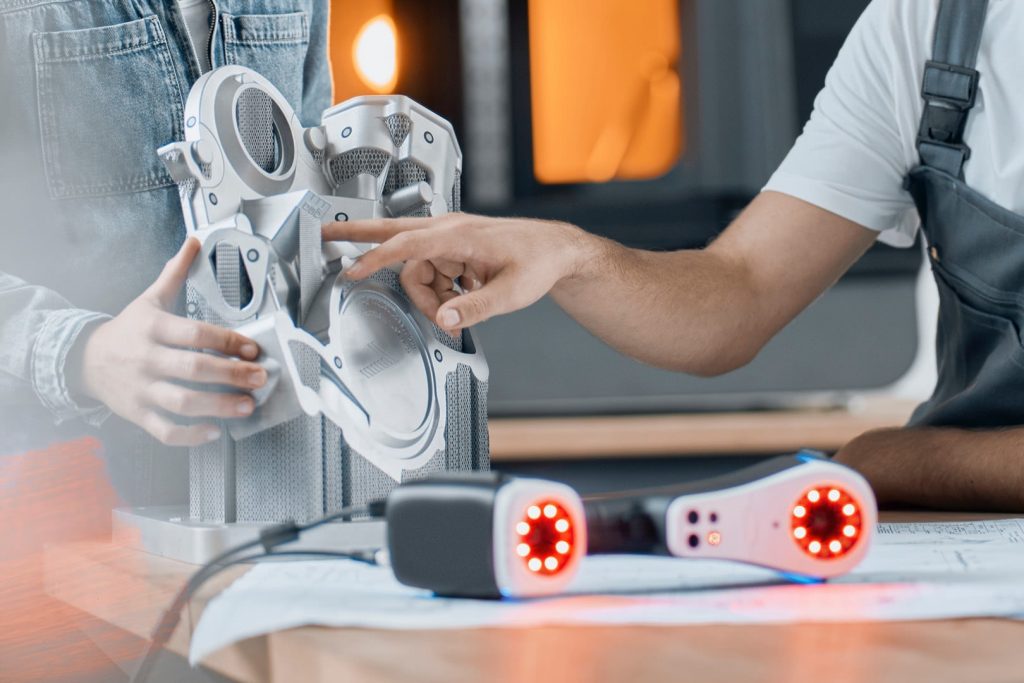

The lightweight ZEISS T-SCAN hawk with GOM Inspect

The 3D scanner T-SCAN hawk is portable, precise and made to make a difference. In combination with the pre-installed GOM Inspect software, it’s a powerful solution that assists you along every step of your task. From capturing high quality 3D data to delivering high quality results: It’s made to simplify processes. It’s made for you.

Made to be portable

The compact T-SCAN hawk 3D scanner is designed to capture data wherever needed. The lightweight, hand-held solution supports you with everything from reverse engineering to quality control – in production and on site.

Made to be precise

The T-SCAN hawk 3D scanner includes impressive technical features, such as photogrammetry of large objects, multiple laser sources and three scanning modes – making it the perfect solution even for fine details or deep pockets. The result: 3D data with maximum precision.

Made to make a difference

The T-SCAN hawk with pre-installed GOM Inspect is a complete solution to simplify your entire workflow from scanning to evaluation and reporting.

Applications

Reverse Engineering

- From shape to CAD model

- Archiving of tools and cultural heritage

- Everything from small details to large parts

Maintenance

- Easy 3D inspection of wear and tear

- Suitable for indoor and outdoor use

- Trend analysis for multiple evaluations

Quality Control

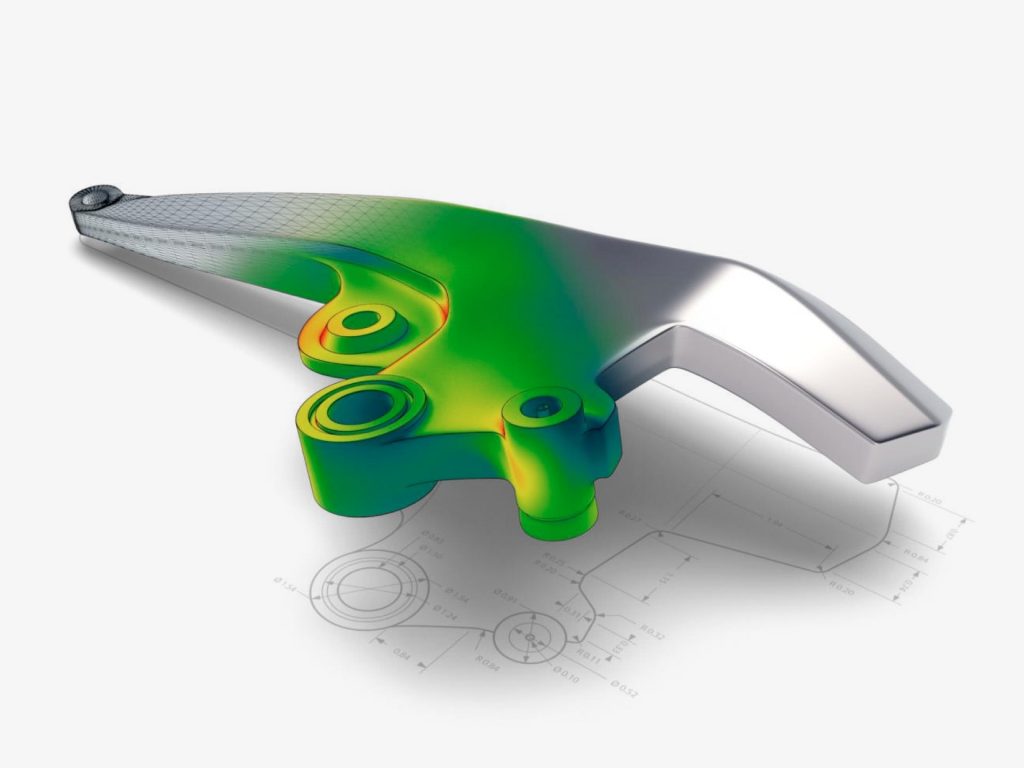

- Nominal-actual comparison

- Functional dimensioning

- Shop floor inspection

GOM Inspect

Making quality visible

GOM Inspect makes just about anything possible: The all-in-one, platform-independent software solution allows the import of 3D data regardless of the measuring system. It supports your entire workflow: from 3D printing and reverse engineering to inspection, evaluation and reporting. It’s the established standard in 3D metrology software – for simpler, faster workflows.

Features

Anything, anywhere

- Compact, lightweight and portable scanner design

- Travel-friendly to support you wherever needed

- Suitable for confined spaces and hard-to-reach areas

Adapts to your needs

- Multiple laser sources for fine details and large areas

- Captures data from almost any surface and material

- For dark and reflective objects and deep pockets

Easy to use and ready to go

- Stand-alone device

- Ready to start in no time

- Easy, intuitive scanning process

Likes a big challenge

- Ideal for very large or heavy object scanning

- Enhanced precision for even larger objects

- Built-in photogrammetry

- Highly reliable results

Three scanning modes at the push of a button

The flexible solution allows you to change scanning modes within one single scan job.

Red crosses: for large areas

For scanning large sections or for fast 3D reconstruction

Blue lines: for fine details

For small parts, fines details or dark, reflective surfaces

Single red line: for confined areas

For deep pockets or hard-to-reach areas

Technical Data

Scan mode

Standard / Single line / Fine mode

Laser source

7 red crosses / Red line / 5 blue lines

Resolution

Up to 0.01 mm

Scanning area

Up to 550 mm x 600 mm

Detailed scan

Supported

Deep pockets

Supported

Built-in photogrammetry

Supported

Accuracy

0.02 mm + 0.035 mm/m

High-precision GOM scalebar

with built-in photogrammetry

Laser class (IEC 60825-1:2014)

Class 2M (eye-safe)

Software

GOM Inspect

Do you want to find out more?

Get in touch with your local #HandsOnMetrology partner.

Discover more

i

Please select the topic you seek more information about

Previous

1/0

Next