Take it.

Make it.

Le matériel adapté à toutes vos mesures sans contact :

ZEISS T-SCAN hawk 2

Portable et précis, conçu et fabriqué par ZEISS

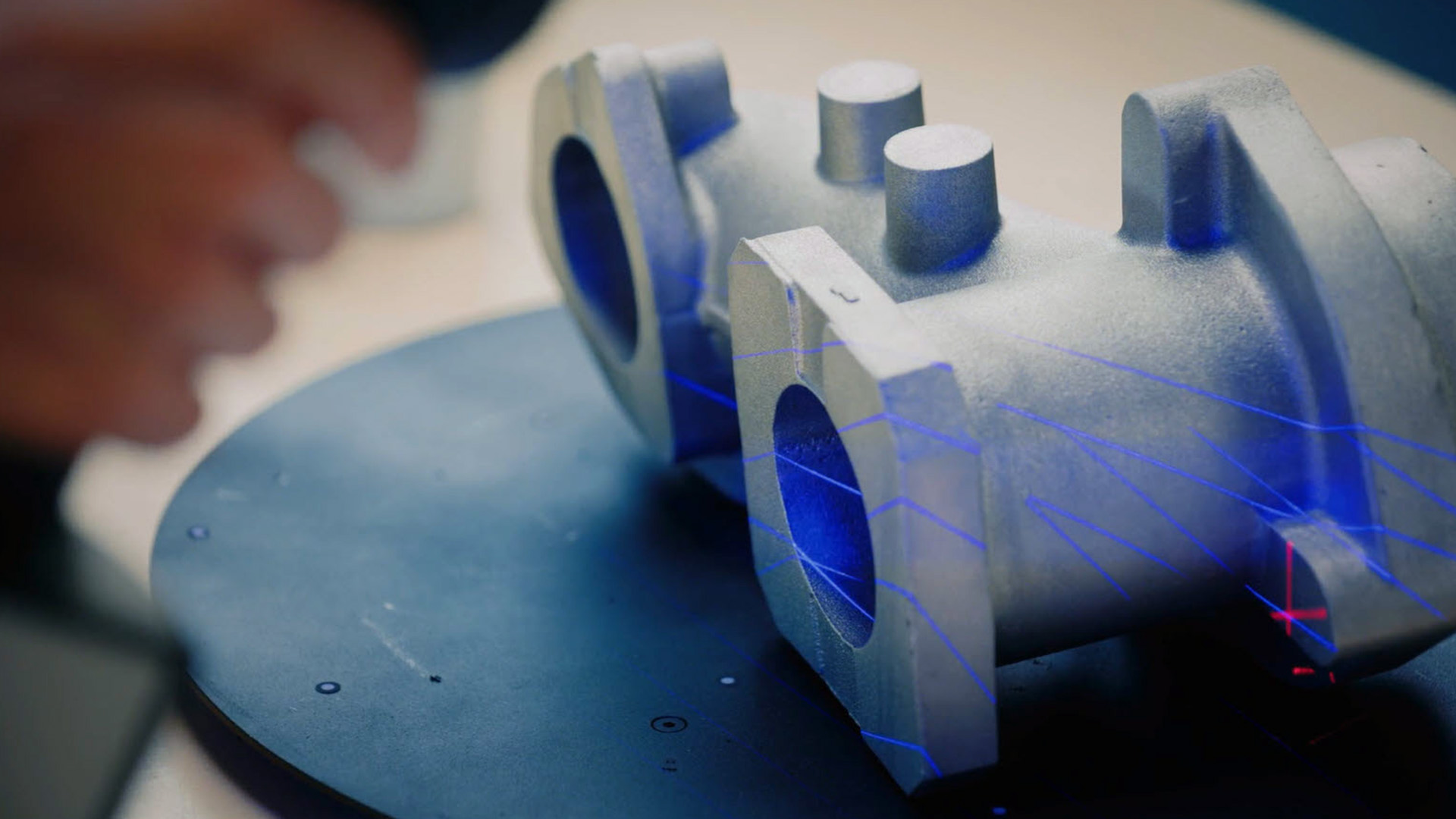

Le T-SCAN hawk 2 est le scanner portable 3D léger de nouvelle génération. Il offre une précision de niveau métrologique et une grande facilité d’utilisation. Quelle que soit la mesure, quel que soit le lieu, ce matériel performant et portable vous accompagne, avec une prise en main rapide.

La distance de travail optimale

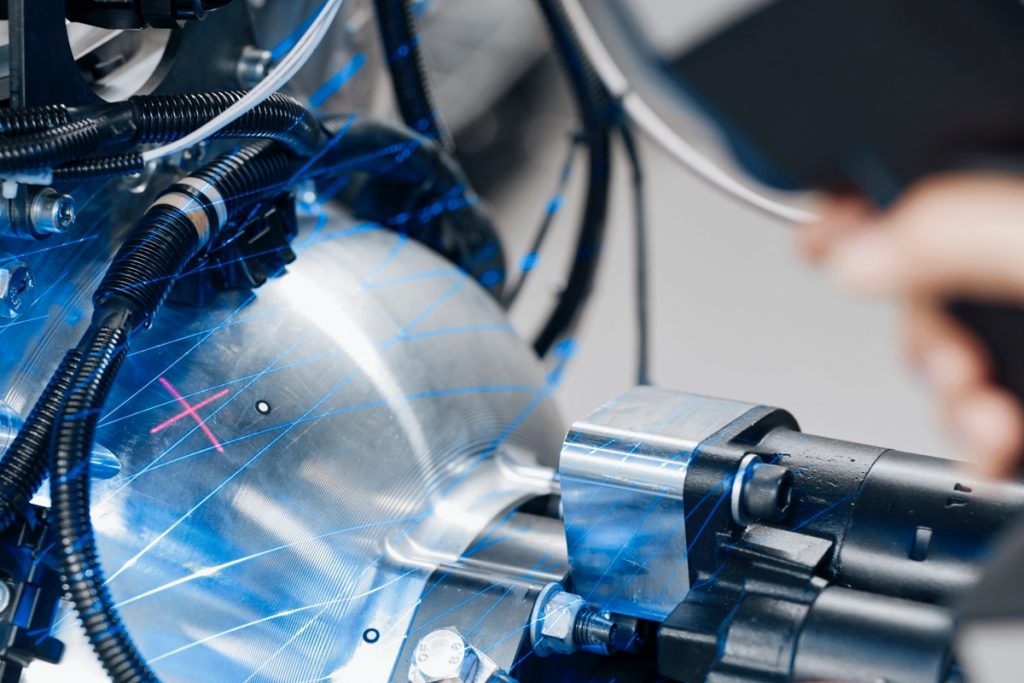

Contrôlez votre distance de mesure avec un nouveau mode de projection – un repère laser rouge vous aide à ajuster facilement la distance pour des résultats de scan optimaux.

Une solution qui s'adapte à votre processus de travail

Une adaptation à votre manière de mesurer – Le T-SCAN hawk 2 offre un maniement intuitif et s’adapte aisément aux mouvements de votre main. Avec la résolution adaptative, vous pouvez passer rapidement à une résolution plus élevée sur une zone spécifique afin d’assurer un balayage optimal.

Voyez plus grand avec le mode satellite

Scannez des objets allant jusqu’à plusieurs mètres de dimension avec le mode satellite. Plus besoin de la photogrammétrie classique intégrée avec des marqueurs codés. Les fonctionnalités logicielles mises à jour garantissent que chaque angle est scanné tout en obtenant des résultats stables et fiables pour des pièces grandes et complexes.

Une numérisation plus rapide des grandes pièces

Avec le volume de mesure étendu du T-SCAN hawk 2, vous pouvez numériser des pièces plus grandes sans effort et avec un minimum de points de référence. Cela garantit des flux de travail rapides et efficaces, même pour des surfaces importantes comme les coques de navires ou les revêtements d’avions.

ZEISS INSPECT – Le logiciel tout-en-un pour l'inspection 3D

Le T-SCAN hawk 2 fonctionne avec ZEISS INSPECT, le logiciel de référence en métrologie 3D intégrée dans la suite logicielle ZEISS Quality Suite. Pendant 30 jours, profitez d’un essai gratuit de la version professionnelle de ZEISS INSPECT :

Caractéristiques

Basculez entre différentes tâches

Le T-SCAN hawk 2 permet un ajustement fluide de la résolution et du champ de vision. Qu’il s’agisse de petites pièces, de détails précis, de grands objets, d’espaces confinés ou de zones difficiles d’accès, ce scanner laser 3D est à la hauteur.

Lancez-vous en toute simplicité

Carl Zeiss GOM Metrology GmbH est un laboratoire accrédité dans les domaines de l’étalonnage des normes de longueur et de coordonnées pour la métrologie optique.

Chaque système T-SCAN hawk 2 est livré avec trois normes de longueur étalonnées par DAkkS, traçables, et une norme de coordonnées étalonnée par DAkkS, traçable, qui sont utilisées pour la qualification du système.

Fonctionnement en une seule pression

Le T-SCAN hawk 2 comporte quatre boutons qui permettent de démarrer et de parcourir votre flux de travail immédiatement. Il n’est pas nécessaire d’exécuter le logiciel séparément sur votre ordinateur portable.

Efficace sur les surfaces sombres et brillantes

Le T-SCAN hawk 2 est capable de scanner une vaste gamme de matériaux et surfaces, et fournit des données de mesure 3D ultra-précises.

Accessoires

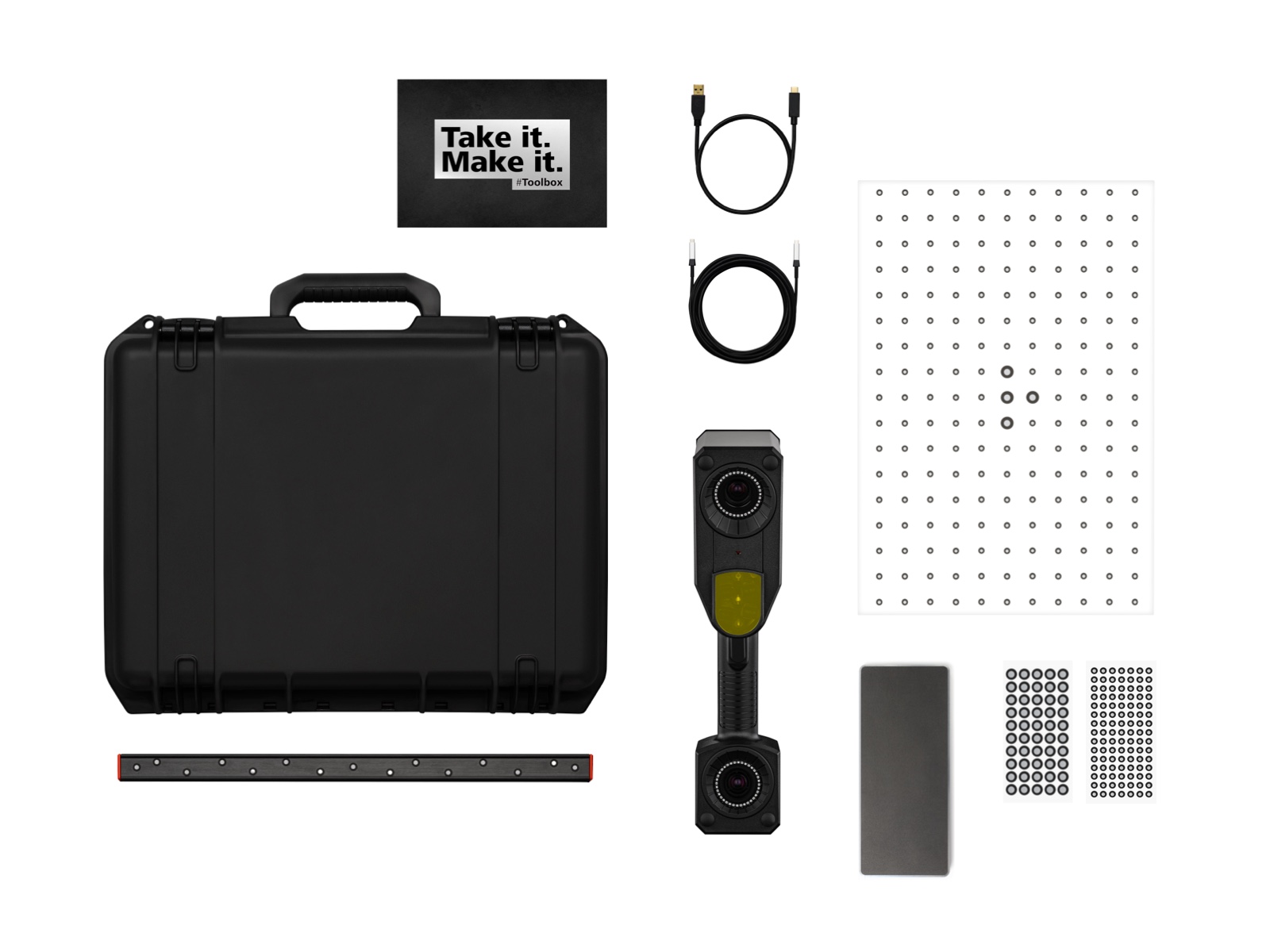

Tout à portée de main, dans une mallette de transport

Que vous l'emmeniez en production ou à l'extérieur, le scanner laser 3D voyage avec vous dans une seule mallette qui contient aussi des outils supplémentaires.

- T-SCAN hawk 2

- Écran de calibrage

- Hyperscale

- Boîte à outils

- Points de référence

- Station d'alimentation

Restez branché et chargé

La station d'alimentation pratique et peu encombrante permet de brancher votre capteur, le boîtier d'alimentation et votre ordinateur.

Éliminez le superflu

Les cartes comportent des points de référence qui permettent de définir et de découper rapidement l'arrière-plan dont vous n'avez pas besoin.

Prêt à prendre en charge de nombreuses applications

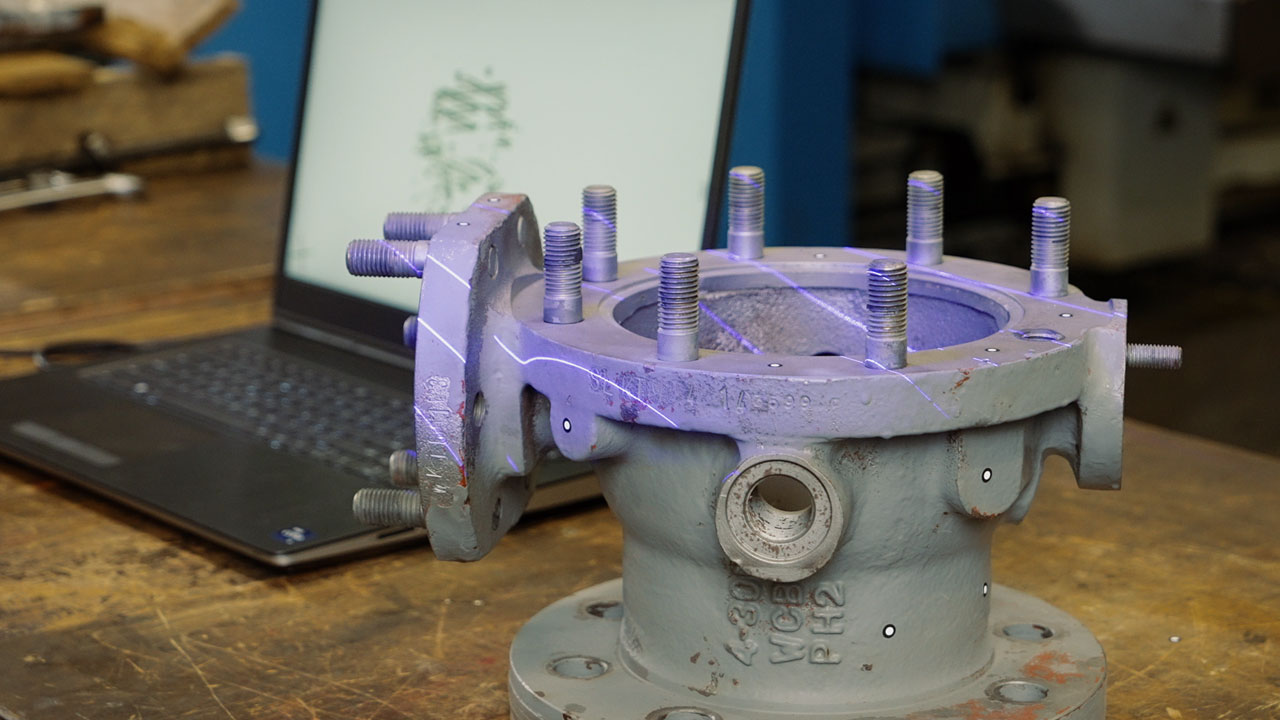

Maintenance

- Inspection 3D des déformations, de la corrosion et des dommages

- Scan 3D et reproduction de pièces d’origine

- En intérieur ou en extérieur, dans les environnements les plus rigoureux

- Surveillance de l'usure

Rétroconception

- De la forme à la CAO

- Outils d'archivage

- Tout type de pièce, des plus petits détails aux très grandes pièces à réparer

Contrôle qualité

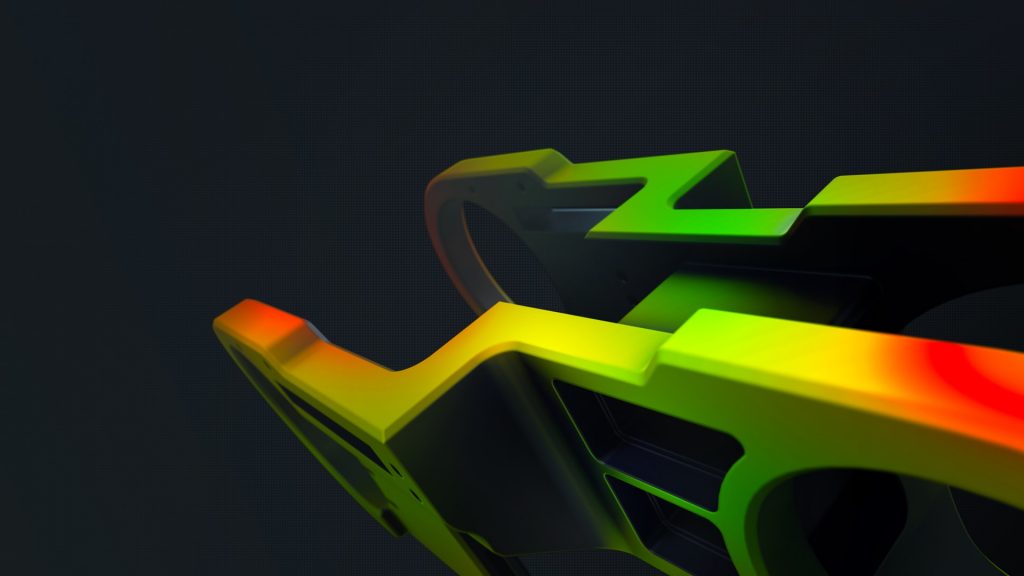

- Comparaison entre les valeurs actuelles et la CAO

- Dimensionnement fonctionnel

- Inspection dans l'atelier de production

- Réduction du nombre d'itérations dans votre processus

Conception

- Numérisation de formes et objets physiques complexes

- Modification de la conception

- Conception intérieure

- Visualisation 3D

Secteurs d’activité

- Automobile, transport, industrie ferroviaire et aérospatiale

- Energie, industrie gazière et pétrolière

- Agriculture, sylviculture et mines

- Industrie lourde, fabrication de moules et machines

Données techniques

(1) D-K-21312-01-00 selon DIN EN ISO/IEC17025:2018

(2) Essai de réception selon ISO 10360

Vous désirez plus d'informations ?

Contactez votre partenaire #HandsOnMetrology local.

En savoir plus

i

Please select the topic you seek more information aboutHow to measure in production

Small and portable: the ZEISS T-SCAN hawk 2 is made for the use in production. See here how it supports your complete process chain from data collection for reverse engineering, different inspection tasks to the digital assembly of produced parts.

Do you want to find out more about the portable 3D laser scanner T-SCAN hawk 2? Visit HandsOnMetrology.com/sessions

How to scan large objects using a portable 3D scanner

Learn how to measure big parts, like sand molds. Roel is using the new Satellite Mode of the ZEISS T-SCAN hawk 2 – replacing the built-in photogrammtry of the previous scanner generation. Together with scale bars, reference points and the big field of view of the handheld sensor, it is a powerful combination which ensures highly accurate data.

How does satellite mode work and why do you need it

Scanning larger parts can be challenging. We simplified the the process with the new satellite mode of the handheld laser scanner ZEISS T-SCAN hawk 2. It does without coded markers thus preparations are easy and fast. Learn more about the advanced way of photogrammetry here. Got any questions? Contact us via support@HandsOnMetrology.com.

How to use a 3D scanner for dent detection

Looking for a way to speed up and refine your aircraft MRO? Let Roel show you how the ZEISS T-SCAN hawk 2 and the Inspect Software aid in various inspection tasks, like GD&T, CAD comparisons or defect maps. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to use a 3D scanner in confined spaces

In this How to Roel is scanning complex and hard to reach areas of a van interior. Whether for inspection or design purposes – the ZEISS T-SCAN hawk 2 is the perfect fit for extracting accurate and complete dimensions in confined spaces. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Unboxing your new 3D laser scanner

Get started with your T-SCAN hawk 2. In this first episode you get to unbox the new hand-held laser scanner together with Aysel. Whether the power cable, the calibration panel or reference points, we got you covered for easy, fast and precise 3D scanning. Have you got any questions about 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: The setup

Want to know what to consider when setting up your new T-SCAN hawk 2? Let Aysel show you an easy step-by-step guide for starting your laptop as well as the system. Get ready for your first scan with the T-SCAN hawk 2! Have you got any questions about 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Your first use of ZEISS INSPECT

In our Getting Started we demonstrate how easy it is to start scanning with the T-SCAN hawk 2. Besides the calibration process, Aysel navigates you through the ZEISS INSPECT software and gives useful tips and tricks for your first scan.

All functions shown are available in the current software version.

Have you got any questions about 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Scanning in ZEISS INSPECT

Have a look at the remote workflow which guides you through different scanning task with ease. Aysel applies the common scanning strategy of scanning one side of the part only. The buttons on the backside of the scanner simplify the process, even when scanning deep pockets.

All functions shown are available in the current software version.

Got a question? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Scanning with reference points

Have a look at how to easily scan both sides of your part using reference points. With just a push of a button on the T-SCAN hawk 2, the guided workflow assists in the scan. The software optimizes the polygonization of the final mesh. Have you got any questions about 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Scanning without reference points

You are scanning a lot of 3D geometries? Then go ahead and try the scanning strategy Aysel presents in this Getting Started: Scanning without any reference points. Just select the right template in the software, define the background plane and start your 3D scan. Have you got any questions? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: The new Satellite mode

In this Getting Started we demonstrate how to accurately scan large parts with photogrammetry. The new integrated satellite mode ensures precise pre-referencing. No other features, like coded markers, are necessary. Watch the video to see the T-SCAN hawk 2 unleash its full potential.

Do you want to find out more about the portable 3D laser scanner T-SCAN hawk 2? Visit HandsOnMetrology.com/sessions

T-SCAN hawk 2: Scanning fine details

Whether you are scanning large parts with local details or a completely detailed part, T-SCAN hawk 2 is the right solution. Let Aysel explain you, how to operate the scanner and get useful tips and tricks for both cases. Have you got any questions? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Scanning deep pockets

Your challenge is to scan deep pockets of a part? The single laser line mode of the T-SCAN hawk 2 allows you to scan even deeper into wholes. Watch the Getting Started to learn more about the detailed scan of hard to reach areas. Have you got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: All features of the remote control buttons

Let Aysel show you the different possibilities of the control buttons on the back of the T-SCAN hawk 2. It makes starting the remote workflow, zooming in and out, opening the menu and more as easy as a push of the button. Have you got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Accessories

You want to scan your parts without sticking reference points on it? We have the right accessory for you: the magnetic reference pillars. Placing them around the part ensures easy, intuitive and accurate data collection. Have you got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Get some useful tips & tricks

Need more tricks on the new T-SCAN hawk 2? Aysel is going to reveal useful tips that make your scanning process even more successful. Get more information on topics, like exposure modes, scanner orientation, defining background planes and customizing workflows. Have you got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to perform fast inspection in electric motorcycle assembly

Components with different tolerances make building safe motorcycles a challenge. Let Alex show you how easy it can be to inspect single motorcycle components and the digital assembly with ZEISS T-SCAN hawk 2 and the inspection software of the ZEISS Quality Suite. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to check welds on electric motorcycle frames

The basic structure of a motorcycle is the welded frame. Weld inspection is therefore necessary not only to maintain quality of parts, but also for customer safety. With the ZEISS T-SCAN hawk 2 and the weld inspection package of the ZEISS Quality Suite, you can easily scan, classify and inspect welds. Let Juan show you how it’s done.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to use 3D scanning for wear control in MRO

Wear and tear of production equipment causes malfunctioning, delays, downtime. In this How to, Roel shows you how 3D scanning is used to implement predictive maintenance – and therefore keep production running efficiently.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to reproduce unavailable spare parts in MRO

Currently facing the challenge of reproducing unavailable spare parts? 3D scanning might be the solution you need to minimize risky downtime. By capturing the dimensions of the equipment, a reproduction is possible in no time. Watch the How to to learn more about it. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to set up a digital warehouse with 3D scanning

3D scanning helps to create your digital warehouse in MRO. With the digital copy you have important information at hand in the event of a sudden defect. Reduce costs due to extended downtime or storage, and easily access your digital inventory where and when you need it. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to 3D scanning for fast and efficient incoming inspection in MRO

Keeping equipment in good condition is necessary for an efficient production process. 3D scanning helps to capture all dimensions of parts for a fast inspection. Roel shows you how reparation or modification of equipment can be done using hand-held solutions. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to scan large parts using ZEISS T-SCAN hawk 2

Looking for an easy and intuitive way to 3d scan large parts up to multiple meter? Then the 3D laser scanner ZEISS T-SCAN hawk 2 with the new satellite mode is the right solution for you. Let Matthias show you how it’s done.

Do you have any questions about ZEISS T-SCAN hawk 2? Contact us via support@HandsOnMetrology.com