Requirements for 3D scanners for small objects

Scanning small objects requires much more than just high resolution. The quality of the scan largely depends on the surface characteristics of the object, the performance of the scanner and software, and the technical capabilities of the device itself. When selecting a suitable 3D scanner for small objects, you should keep the following requirements in mind:

Accuracy & resolution

Small objects often have complex geometries that require high point density and exceptional detail. The required accuracy is often within the micrometer range.

Surface characteristics

Shiny, dark, or transparent materials are particularly challenging to capture accurately. While simple systems like depth cameras often fail to provide usable data, high-quality 3D scanners with powerful cameras and software deliver reliable results even on difficult surfaces.

Scan results & precision

When scanning small objects with intricate geometries, consistent point clouds and clean polygon meshes are essential. Only if the 3D scanner for small objects can capture even the finest structures evenly and without gaps can precise models be created for analysis, reverse engineering, or 3D printing.

Scanning speed & workflow

For small 3D scanners, overall process efficiency determines productivity. High scanning speed per second and time-saving post-processing allow models to be processed quickly without sacrificing quality.

Software integration

To perform well in practice, a 3D scanner for small parts should be seamlessly integrated with common CAD, CAE, and 3D printing software. A continuous data flow ensures that scanning results can be analyzed and processed without additional steps.

Ergonomics & flexibility of the scanner

Scanning small objects often requires a flexible system. Portable 3D scanners offer a clear advantage when capturing delicate geometries or hard-to-reach areas with consistent accuracy.

A powerful 3D scanner for small objects combines precision, speed, and software support, adapting perfectly to individual applications and everyday engineering requirements.

Practical applications of 3D scanners for small parts

3D scanners for small objects are used across a wide range of industries. The following application examples illustrate just how versatile these systems have become in modern workflows:

Quality control

For capturing small components during series or individual inspections, 3D scanners provide a reliable basis for nominal-to-actual comparisons, surface analysis, and verification of manufacturing tolerances.

When technical drawings are missing or parts need to be reproduced, a 3D scanner for small parts can accurately capture the geometry. The resulting models serve as the foundation for reconstruction, adjustment, or repair. For more insights into real-world applications, see our article on reverse engineering of parts and damaged components.

3D printing

A 3D scanner captures fine details with precision and processes the scan data so it can be used directly for additive manufacturing or integrated into design and development workflows.

Prototyping

Even for small objects, rapid prototyping plays an important role in creating concept models for simulations or functional testing, for example, in product development and research.

ZEISS 3D scanners for small objects

Those who need to capture small objects in high resolution and with maximum accuracy require specialized systems with finely tuned technology. ZEISS offers a range of 3D scanners for small objects that deliver exceptional precision, even when scanning complex geometries or delicate materials. These advanced small 3D scanners provide accurate results, dense point clouds, and exportable 3D models for CAD, CAE, or 3D printing applications.

T-SCAN hawk 2

T-SCAN hawk 2 is a portable 3D scanner for small objects that combines high flexibility and precision, making it equally effective for large or hard-to-reach components. As a handheld scanner, it is particularly well suited for applications in quality assurance, reverse engineering, and mechanical engineering.

Key advantages of T-SCAN hawk 2:

- Handheld scanner with intuitive operation, no complex setup required

- Precise capture of complex geometries, even on shiny or dark surfaces

- High scanning speed

- Compact device for flexible use directly at the object

GOM Scan 1

GOM Scan 1 is a compact 3D scanner for small objects, designed to deliver highly detailed results. Using structured light projection and high resolution, it is ideal for prototyping and quality assurance tasks.

Key advantages of GOM Scan 1:

- Optimized for small objects with fine measuring fields and high resolution

- Uses structured light technology, perfect for detailed scans and complex surface textures of small parts

- Easy to operate with an intuitive user interface

- Compact design for use in confined spaces

ATOS Q

ATOS Q is a high-precision, all-round 3D scanner for small objects with interchangeable measuring volumes. It is perfectly suited for serial inspections, development processes, and quality assurance, especially when it comes to the precise digitization of small components and intricate parts.

Key advantages of ATOS Q:

- Extremely high scan resolution for delicate geometries and fine surface details

- Interchangeable measuring fields, adaptable to various object sizes

- Can be used manually or integrated into automated workflows

- Delivers complete and reliable data for CAD comparisons and inspection reports

- Specifically designed for use in demanding industrial environments

ZEISS software solutions for analysis and reverse engineering

Scan points alone are not enough to make reliable statements about the quality, shape, or function of a component. Only targeted data processing makes the information usable for industrial applications. ZEISS offers powerful software solutions for this purpose: ZEISS INSPECT and ZEISS REVERSE ENGINEERING integrate seamlessly into existing workflows and provide dependable support for tasks such as quality assurance and reverse engineering.

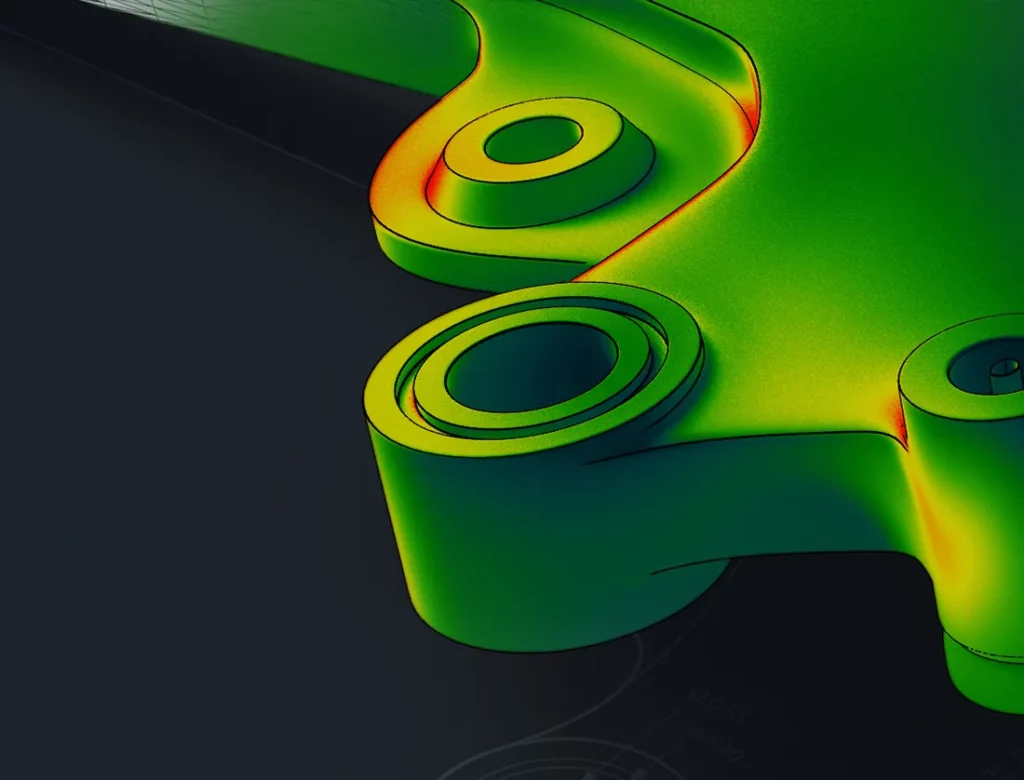

ZEISS INSPECT

ZEISS INSPECT generates precise 3D models from scan points and enables visual analysis of surfaces, dimensional deviations, and quality characteristics. With accurate measurement functions, comprehensive inspection reports, and a wide range of export formats, the software is ideal for industrial applications such as 3D printing, CAD processing, or simulation.

Even when working with complex geometries and high-resolution data, ZEISS INSPECT delivers reliable results. It integrates seamlessly with all ZEISS 3D scanners, including GOM Scan 1 and ATOS Q.

ZEISS REVERSE ENGINEERING

ZEISS REVERSE ENGINEERING enables the precise creation of CAD-ready models from scanned point clouds or polygon meshes. The reconstruction process can be carried out automatically or manually, even for complex freeform surfaces. With intelligent geometry recognition and surface-fitting functions, cylinders, planes, and radii can be reliably reconstructed. Common export formats such as STEP or IGES are supported, allowing results to be transferred directly into existing CAD systems.

The software is ideal for reverse engineering components, for example, when technical drawings are missing, or for optimizing existing products. Thanks to its seamless integration with ZEISS INSPECT, switching between analysis and design is effortless.