Innovative ideas meet traditional motorcycle race

The 24 Hours of Le Mans motorcycle race is an endurance motorcycle race that has been taking place at the Circuit Bugatti in Le Mans, France, since 1978. Organized by the Automobile Club de l’Ouest, it is part of the FIM Endurance World Championship. In 2024, the non-profit organization Sigma Regen Superbike was part of the event. 20 students from the mechanical department of Sigma Clermont were engaged in the realization of a truly unique motorcycle – combining performance and sustainability.

Application goals for the 24 Hours of Le Mans

For the attendance at the race, there are several development measures in mind. The center of their consideration is to drive innovation when it comes to consumables and energy in competition. The following goals are defined of the student group in order to stand out from the competitors:

1.

Integrating an electric motorization using as much of the standard motorcycle components as well as commercial components.

2.

Integrating an innovative energy regeneration system.

3.

Integrating a quick battery change system for the race.

4.

Use competition as a laboratory to accelerate prototype development.

5.

Participate in the 24 Hours of Le Mans Moto in the „Experimental” Category and become the first electric motorcycle to finish the race and win the EWC cares trophy which rewards the social and environmental actions of the racing teams.

Improving motorcycle prototyping with 3D scanning

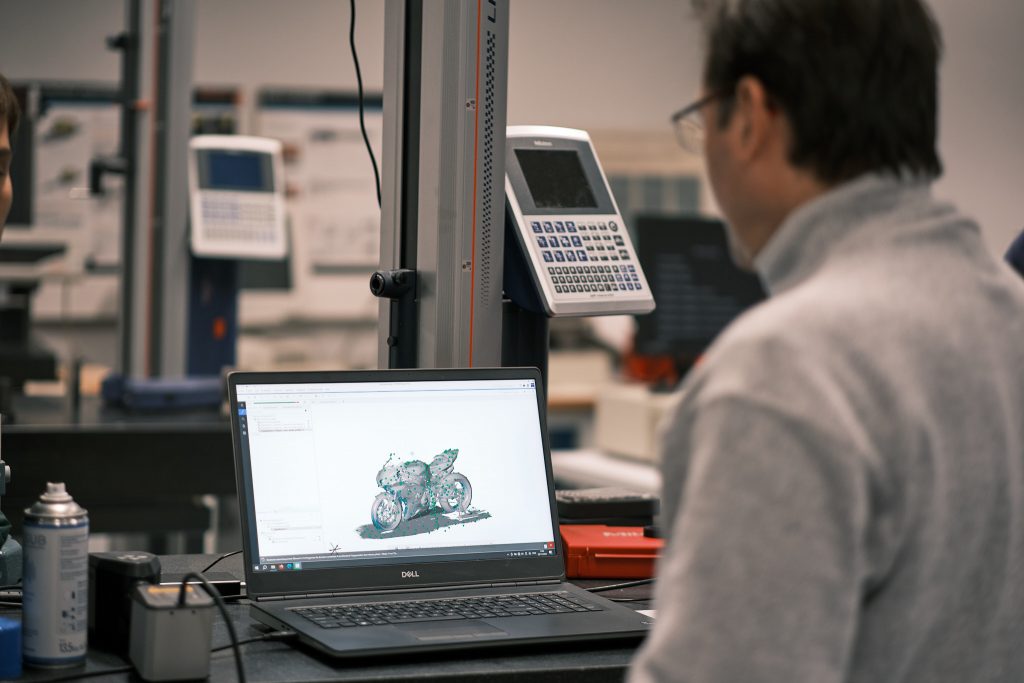

For their prototyping project, the students reached out to our French partner Check3D.

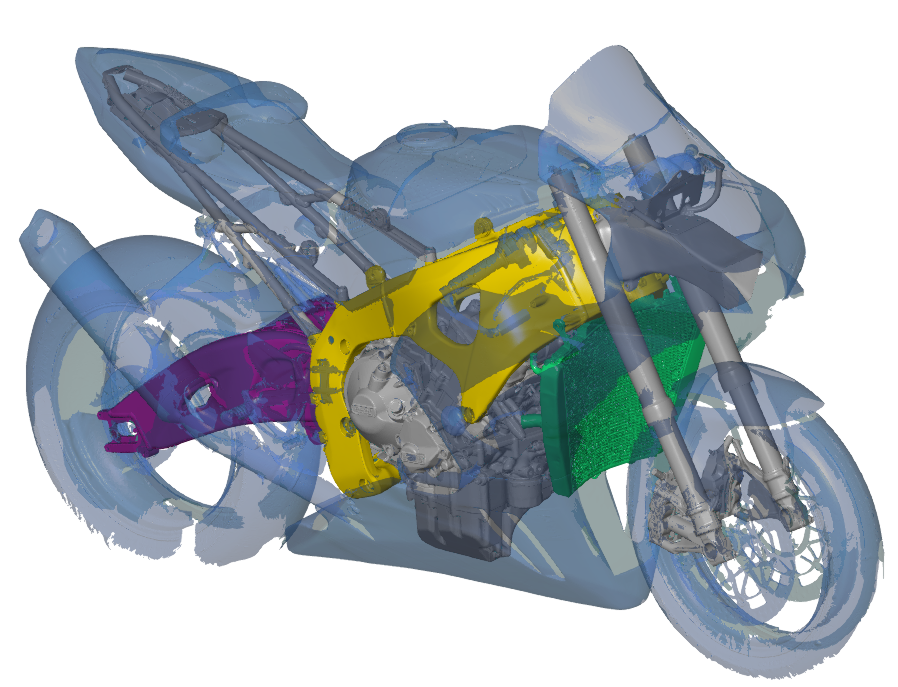

Based on their task to scan an entire motorcycle quickly and accurately, the 3D laser scanner ZEISS T-SCAN hawk 2 was the recommended tool. Its intuitive and guided workflows allowed each of the students to work independently on their vision of the motorcycle. The biggest challenge, however, was capturing a wide variety of different parts, including small and big parts as well as shiny surfaces with different colors. This difficult situation was successfully mastered with ZEISS T-SCAN hawk 2. Its various modes for different object sizes and surface characteristics delivered high quality 3D data for the prototyping process. To align each scanned part digitally before the real assembly, ZEISS INSPECT software was used. It offered a first impression of the alignment and possible weak points.