Changing the future of transportation with 3D scanning

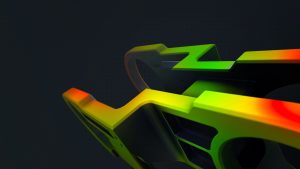

B-TECHNOLOGY is transforming the future of transportation with an innovative flying-driving drone and the Beccarii car. Utilizing advanced 3D scanning, they ensure precision and quality in their groundbreaking designs.