Quality control in the supply chain

Accelerating quality control with 3D scanning

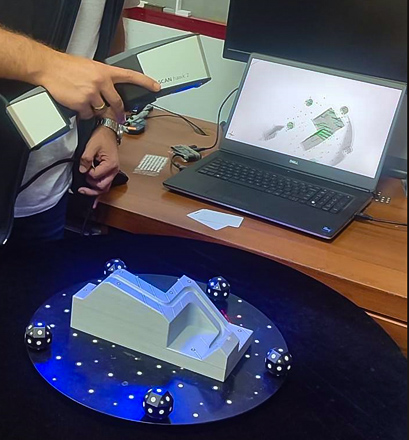

In their search for a suitable, precise solution that would eliminate measurement uncertainties and support additional interventions on the products, they found the new hand-held ZEISS T-SCAN hawk 2.

The lightweight and compact design of the scanner is particularly impressive, enabling universal use – regardless of the location. In addition, the use of scanning spray is no longer necessary thanks to the powerful laser technology. Any surface can now be scanned and inspected without any preparatory work.

Thanks to ZEISS T-SCAN hawk 2, we've accelerated our quality control processes by 80%.

Ela Küçükçiftçi / Quality Control and Assurance Executive - KONVEYÖR

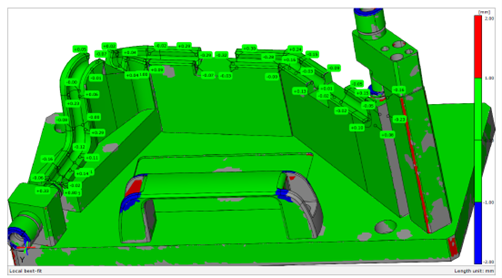

Product evaluation in ZEISS INSPECT software

For the reporting to the supplier companies, KONVEYÖR uses the certified ZEISS INPSECT software. The solution delivers repeatable dimensional accuracy for each product. This ensures error-free deliveries and allows to proactively identify and address any issues that may arise, preventing recurring workflow problems.