Cuando lo que importa es el interior

ZEISS METROTOM 1 es sinónimo de facilidad de uso, datos 3D precisos y control de calidad de afuera hacia adentro.

Análisis en profundidad con un solo escaneado

Rápido, intuitivo y sumamente preciso

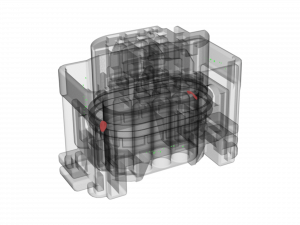

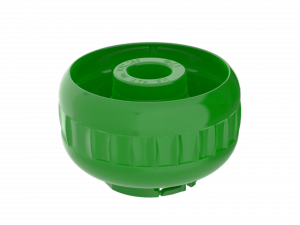

ZEISS METROTOM 1 es tu vía rápida: captura datos 3D precisos sin tener que preparar las piezas previamente. Con tecnología de tomografía computerizada, que te permite escanear piezas de forma no destructiva y ver el interior. Mide, analiza e inspecciona defectos ocultos y estructuras internas. En combinación con el software ZEISS INSPECT, alcanza una nueva dimensión que simplifica tu control de calidad.

Un sistema compacto y fácil de usar para capturar los datos para tus tareas

El sistema fácil de usar permite a varios usuarios comenzar el proceso de medición y capturar datos precisos. Caracterizado por sus dimensiones compactas, METROTOM 1 se integra sin dificultades en tus instalaciones. Un solo paso pulsando un botón te permitirá comenzar a realizar mediciones e inspecciones en sitio. Para minimizar el mantenimiento, esta solución inteligente y compacta está equipada con un tubo de rayos X cerrado.

Captura de datos 3D sin preparación de las piezas

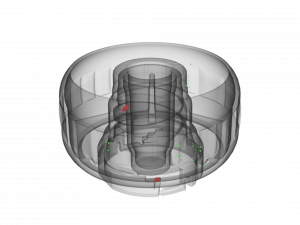

Con METROTOM 1 puedes inspeccionar estructuras internas y defectos mediante un escaneo no destructivo. El proceso de medición no requiere ninguna preparación previa de la pieza. Mientras que escaneas la pieza siguiente, puede inspeccionar o realizar ingeniería inversa de la anterior.

Escaneo múltiple de piezas

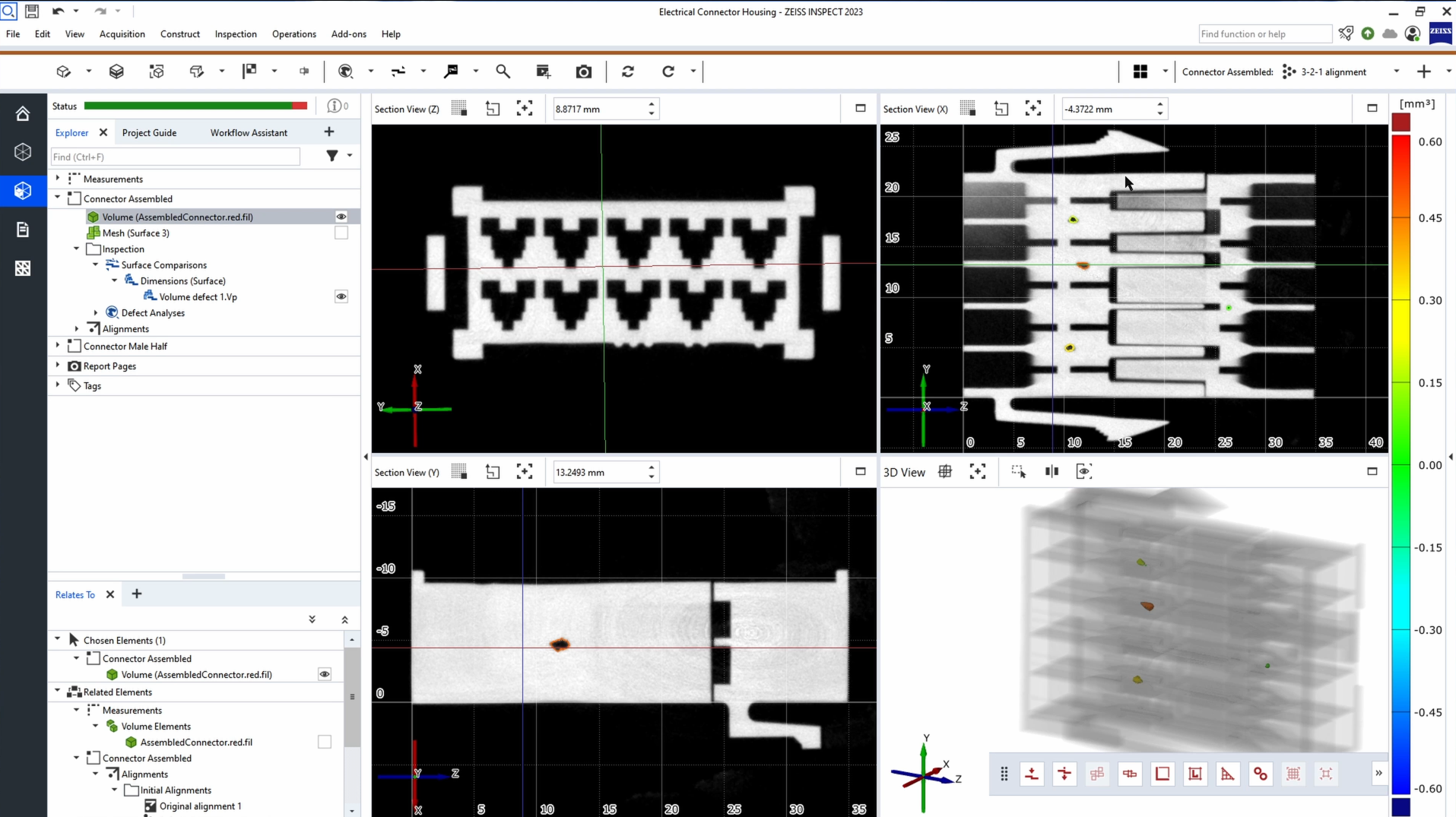

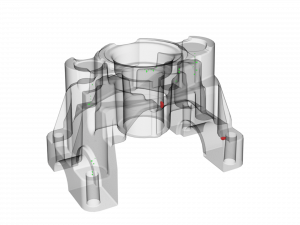

La medición simultánea de múltiples piezas es una de las características más eficientes de METROTOM 1. La fórmula es sencilla: cantidades elevadas con un uso óptimo del volumen de medición. El resultado: tiempos de escaneo por pieza más rápidos sin comprometer la calidad. ZEISS INSPECT separa y evalúa automáticamente cada una de las piezas, de forma que los resultados están disponibles rápidamente en forma de reportes.

Inspección de estructuras internas y defectos

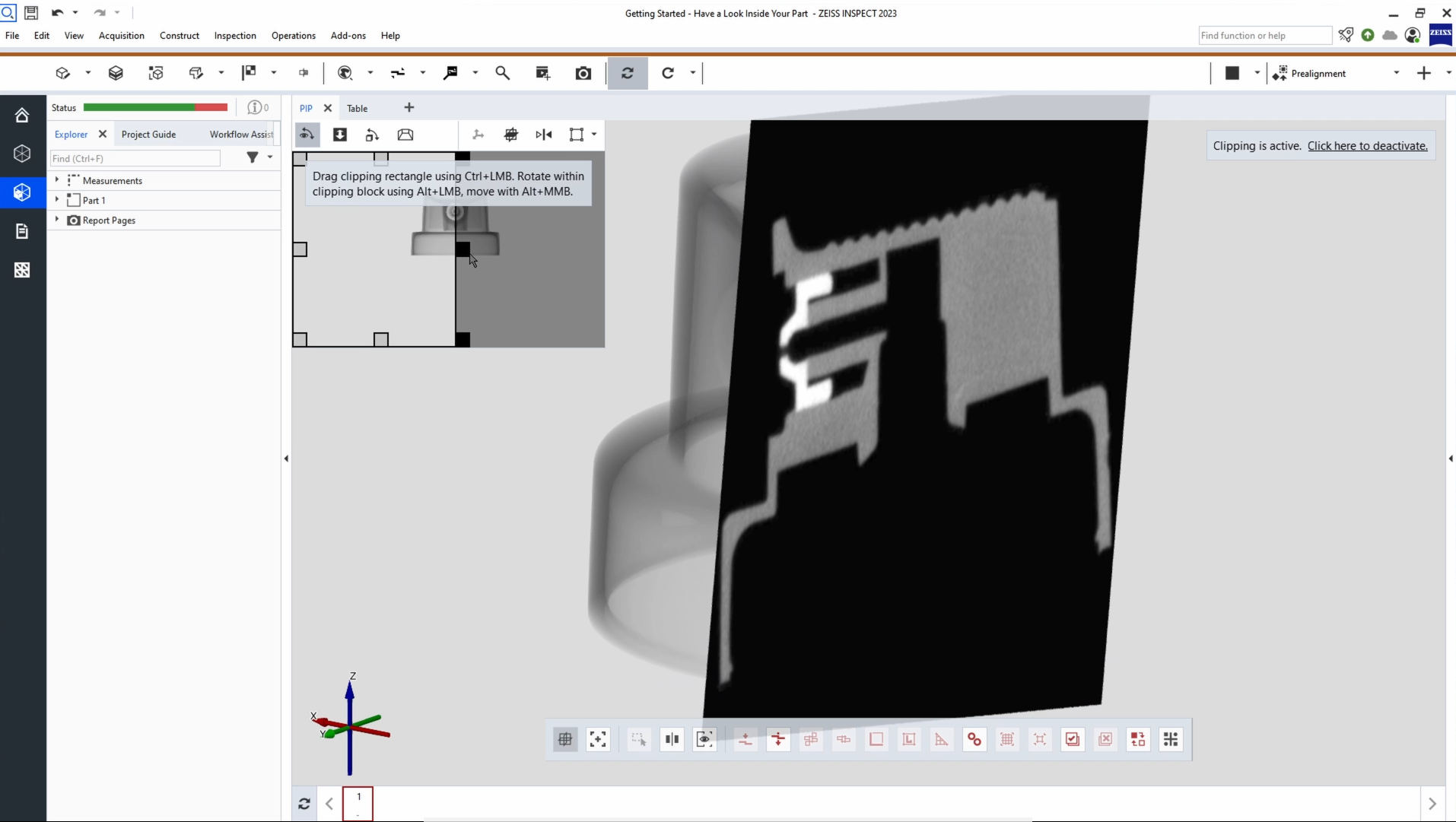

METROTOM 1 con ZEISS INSPECT te guía paso a paso en todo el proceso de medición. Con visualización de volúmenes e inspección de sus datos escaneados, puedes descubrir todas las dimensiones de tus piezas, incluso las ocultas. El escaneo de todas las estructuras internas y externas facilita la ingeniería inversa de las piezas.

Sencillo y eficiente. Con tan solo un escaneo. METROTOM 1 le asiste con:

- Escaneo 3D de componentes pequeños a medianos

- Medición precisa

- Inspección y control de calidad

- Análisis profundo de piezas rechazadas

- Inspección de componentes con respecto a su CAD

Un concepto inteligente todo en uno

La tensión, la potencia, el tiempo de exposición y el número de pasos son algunos de los parámetros de medición importantes en la tomografía computerizada (CT). Trabajando con ZEISS INSPECT, ZEISS METROTOM 1 incluye una determinación de parámetros automatizada para estos valores. El software te proporciona unos valores iniciales óptimos para reducir la complejidad de la configuración de su escaneo. METROTOM 1 se basa en una operación sencilla, una adquisición rápida y unas funciones de evaluación intuitivas. Un concepto todo en uno en el que puedes confiar.

Características

Compensación de temperatura activa para unos resultados precisos

Resultados de medición de alta precisión

La precisión de cada METROTOM 1 se comprueba tanto durante la producción como adicionalmente en sitio, una vez instalado. La comprobación de la precisión se realiza con un artefacto de ensayo calibrado y certificado DAkkS.

El escáner se puede recalibrar en cualquier momento en sitio utilizando el objeto de calibración.

Guiado digitalmente por ZEISS INSPECT para unos resultados óptimos

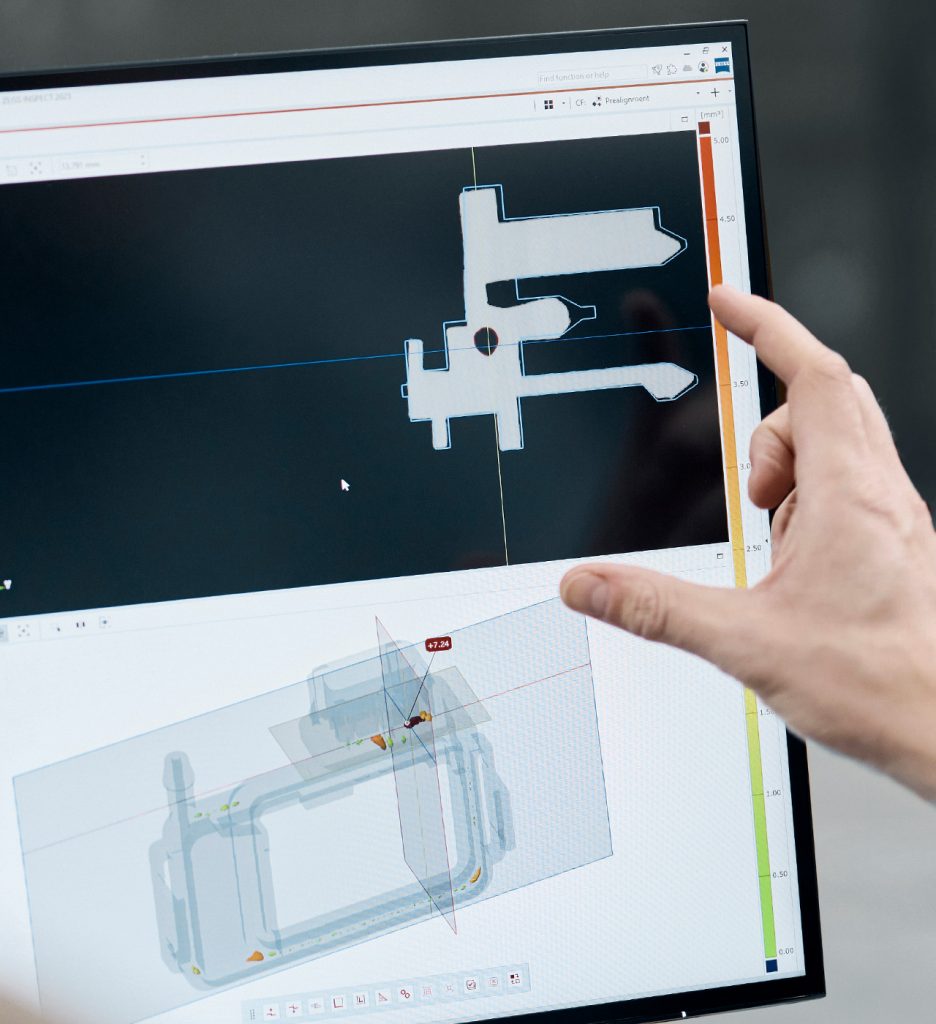

METROTOM 1 funciona con ZEISS INSPECT, la solución de software todo en uno centrada en el usuario y el estándar acreditado en la metrología 3D. Potentes funciones como la visualización y la inspección de volúmenes, la metrología dimensional, los análisis y las comparaciones de tendencias, la detección y la inspección de defectos, la convierten en la herramienta perfecta para aprovechar todas las capacidades del sistema.

Cada aplicación tiene requisitos diferentes

Mide de forma sencilla cualquier cosa dentro de un volumen de medición de 165 x 140 mm. El volumen de medición puede ajustarse con precisión digitalmente. A su vez, puedes ajustar la resolución para acelerar el proceso y conseguir unos tiempos de escaneo rápidos conforme a tus necesidades.

Accesorios

Incluido con METROTOM 1

El compacto sistema está equipado con:

- Objeto de calibración

- Modo de escaneado continuo

- Estación de operación

- ZEISS INSPECT

- Detector 2,5k desarrollado por ZEISS

- Generador de rayos X 160 kV

- Armario de temperatura controlada

- Control de temperatura activo

- Mesa de rotación automática de 360 grados – capacidad para 5 kg de piezas

Aplicaciones

Aplicaciones ilimitadas

Una amplia gama de aplicaciones

- Comparación nominal/real de CAD y pieza

- Medidas dimensionales

- Inspección de sección a cualquier profundidad de la pieza

- Análisis de la distribución del grosor de la pared

- Dimensionamiento funcional para primer artículo

- Corrección de primera pieza asegurada mediante el escaneo de múltiples muestras producidas con distintos parámetros

- Reducción del número de iteraciones en su proceso

- Monitorización del proceso de producción mediante la inspección rápida de múltiples piezas

- Captura real tras la aprobación de la herramienta

- Compensación de alabeo del componente

- Examen de productos muy exigentes como objetos transparentes y polímeros blandos

- Análisis funcional y de error de conjuntos

- Análisis de defectos de material no destructivo, p. ej., sopladuras, poros o grietas

- Ingeniería inversa de piezas existentes o geometrías de piezas

- Validación de diseños

Datos técnicos

¿Deseas más información?

Ponte en contacto con tu distribuidor local de #HandsOnMetrology.

Saber más

i

Please select the topic you seek more information aboutMETROTOM 1: The Setup

The 3D scanner ZEISS METROTOM 1 is powered by CT technology and allows you to inspect internal structures that can’t be detected with tactile or optical measuring systems. Sounds interesting? In this Getting Started video Aysel and John will teach you how to set up the hardware. Find out how to power up. Discover the scanner’s control hardware with all its switches, buttons and functions. Then learn how to connect the solution to the software ZEISS INSPECT and warm up the X-ray tube.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

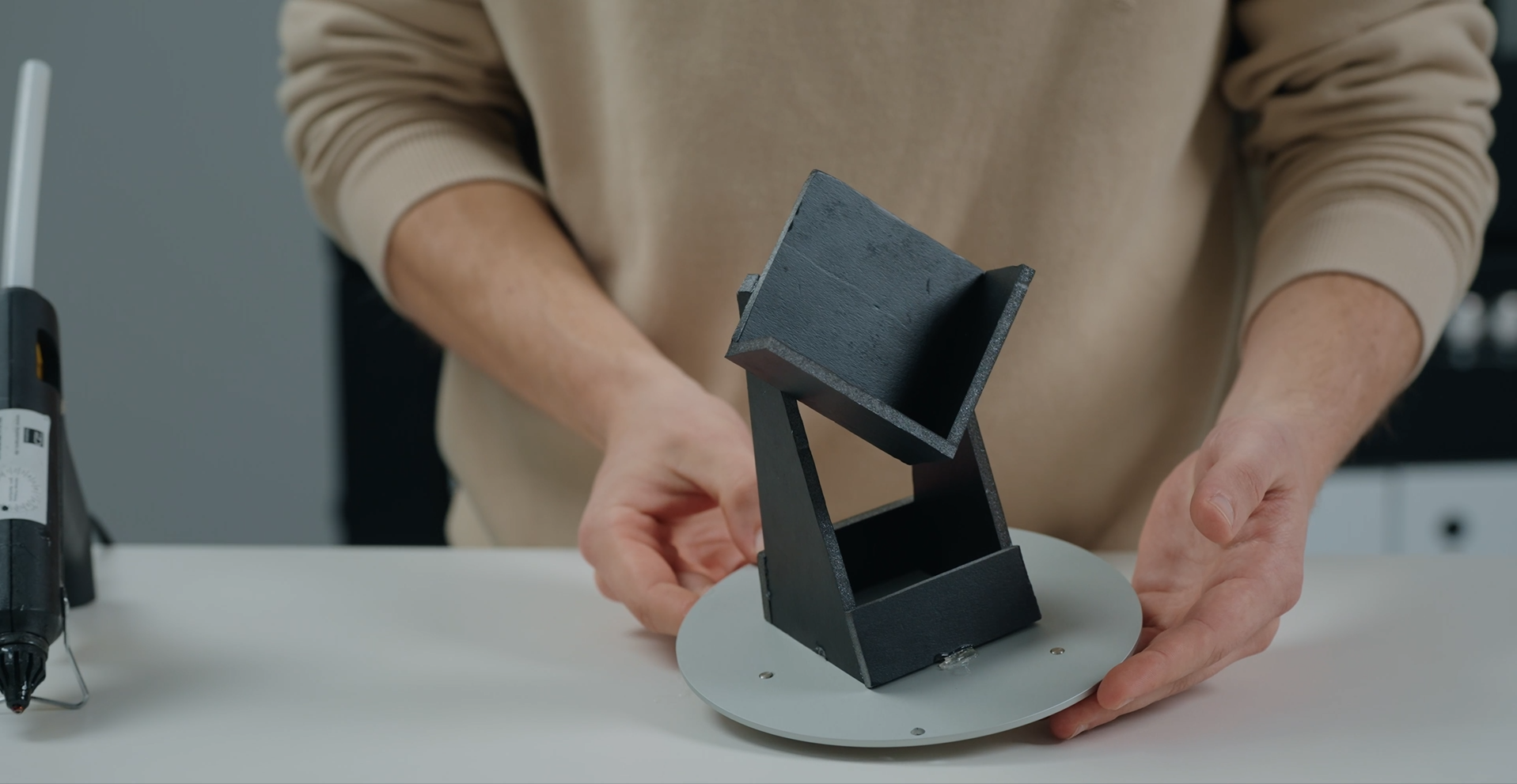

METROTOM 1: Easy part fixture

So you got yourself the 3D scanner ZEISS METROTOM 1 – powered by CT technology – and want to learn how to fix a part so it won’t move during the scan? In this Getting Started video Aysel and John will show you a few quick and cost-efficient tricks for creating the perfect part fixture. Watch the two 3D experts as they get crafty with insulation foam and hot glue before placing their part on the fixture plate and locking it into the rotation table inside the system.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Introduction to ZEISS INSPECT

ZEISS METROTOM 1 – powered by CT technology – is yet another 3D scanning solution that fully reaches its outstanding potential once connected to the software ZEISS INSPECT. Follow Aysel and John, as they take you into ZEISS INSPECT via the ZEISS Quality Suite, and get a quick tour around the four different workspaces, dedicated to scanning, inspecting, reporting and mesh editing.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Scanning single parts

You want start your first 3D scan with ZEISS METROTOM 1 so you can inspect the internal structures of a part via CT technology? Then watch Aysel and John’s Getting Started video first: Their step-by-step tutorial takes you through the basic scanning strategy of scanning a single, transparent plastic part. You’ll learn about all the adjustments to be made on the METROTOM 1 before the scan – including the adjustment of the filter wheel and the x-ray tube parameters voltage, power and exposure time. Just follow them along – it’s easy.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Scanning multiple parts

The 3D scanner ZEISS METROTOM 1 – powered by CT technology – is perfect for scanning multiple parts at once, as it seriously reduces scan times. Interested? Then watch Aysel and John’s tutorial. Learn how to prepare the parts for 3D scanning, discover how to set up the software – and experience its simple, built-in separation tool: for separating out the batch volume into smaller volumes for each individual part.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

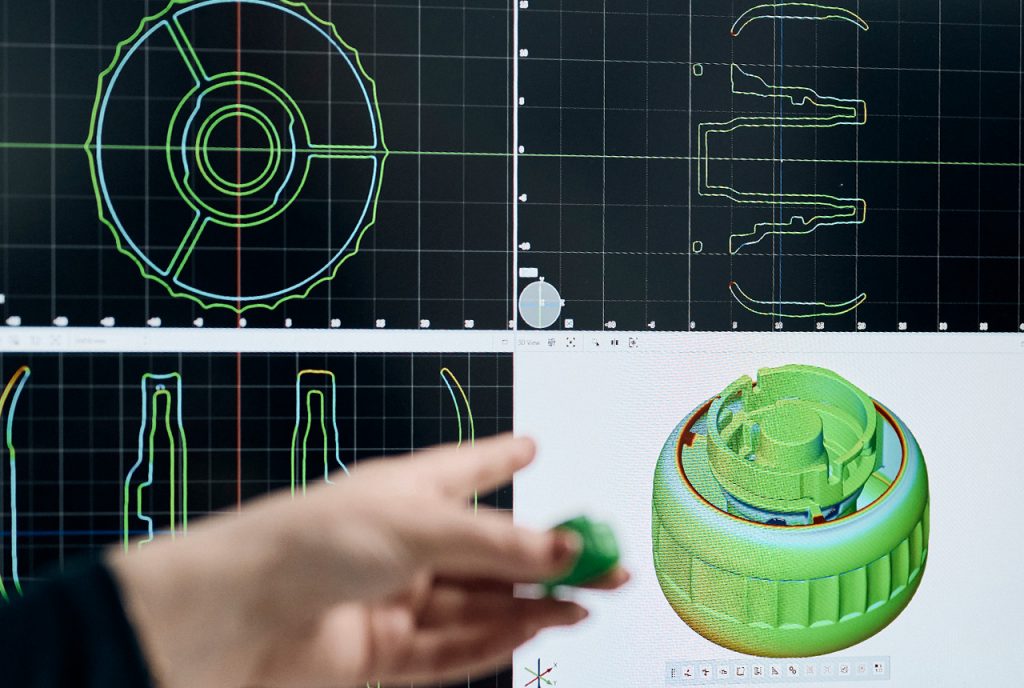

METROTOM 1: Easy volume visualization

When combined with the software ZEISS INSPECT, the 3D scanner ZEISS METROTOM 1 offers incredible advantages for the inspection of internal defects – and John and Aysel know all the visualization tricks. Follow their tutorial to learn about slicing through a part in order to look inside. Scroll through parts with the clever picture-in-picture view. Choose the multi-view function for a view of all three directions. And get several insights at a single glance by making the mesh and CAD visible, too.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

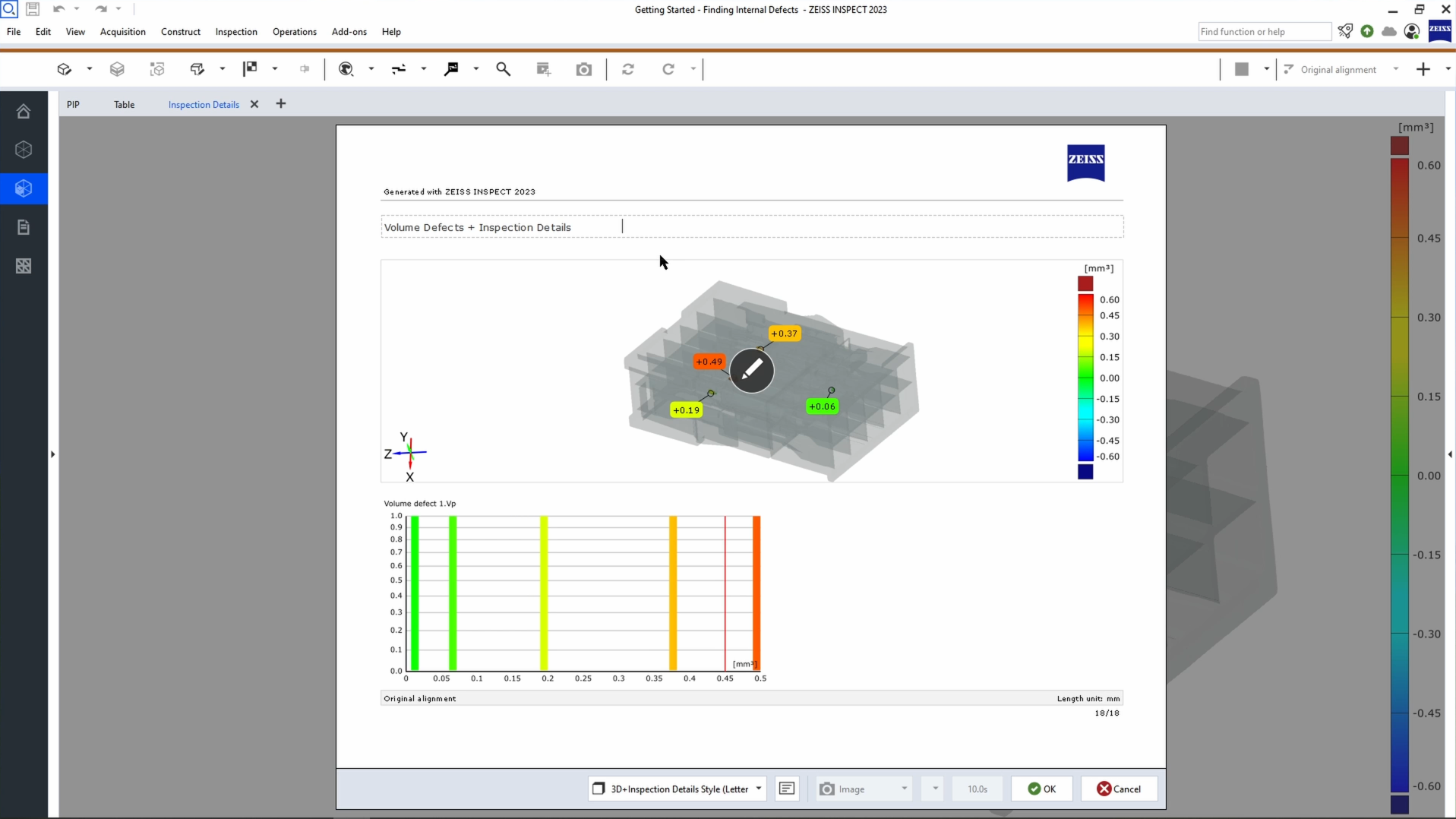

METROTOM 1: Easy internal defect inspection

You’re looking for a solution to help you locate and classify internal part defects? Then ZEISS METROTOM 1 – powered by CT technology – is the perfect solution and this video teaches you how it’s done. Learn how to do automated, high-quantity internal inspections on the digital twin of any part. Take a look at all aspects of a defect – from porosity percentage or defect volume to defect length or defect distance to the surface of the part.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Quick & easy calibration

In this video, Aysel and John will show you how to calibrate the 3D scanner ZEISS METROTOM 1. The solution comes with a calibration object and fixture device so you can recalibrate at any time. Good news: The software ZEISS INSPECT guides you through the process. After that, your METROTOM 1 is ready for 100 % accurate 3D scanning.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Automated parameter selection

What makes the use of your 3D scanner ZEISS METROTOM 1 even more convenient? Automated parameter selection: a standard function in ZEISS INSPECT. Sounds interesting? In this video you’ll learn how to let the solution calculate suitable parameter settings for you – based on part shape, thickness, density and desired scan resolution. Time for you to sit back and wait for the magic to happen.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

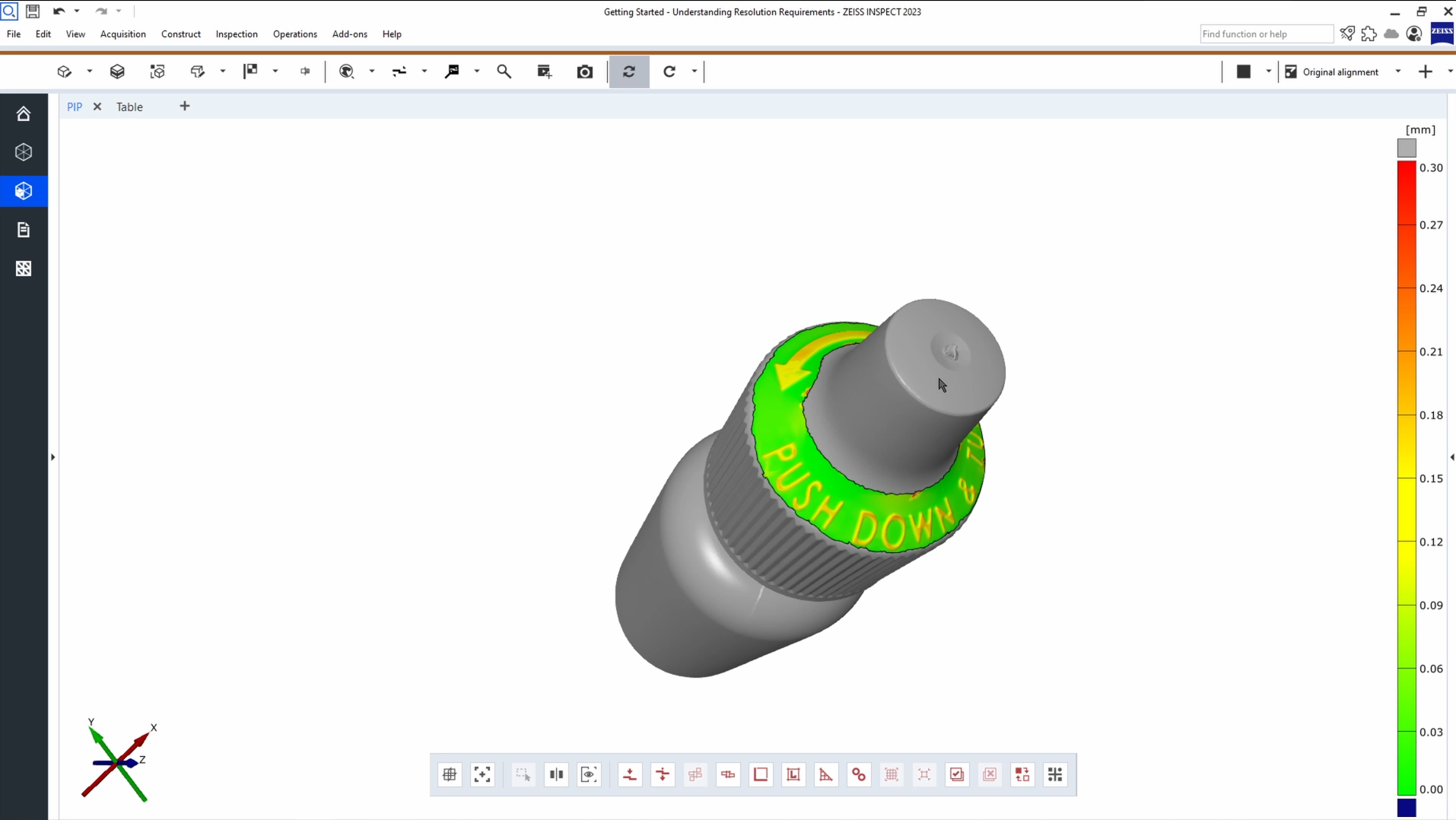

METROTOM 1: Introduction to scan resolution

The 3D scanner ZEISS METROTOM 1 – powered by CT technology – is a versatile system with a useful set of pre-defined scan resolutions to cover a wide range of objects and measuring tasks. In this Getting Started video you’ll get an introduction to scan resolution requirements. You’ll learn how to calculate a suitable resolution with a simple rule of thumb. You’ll discover the advantages of 3D scanning in a lower or higher resolution. And you’ll discover the system’s most commonly used resolution settings.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

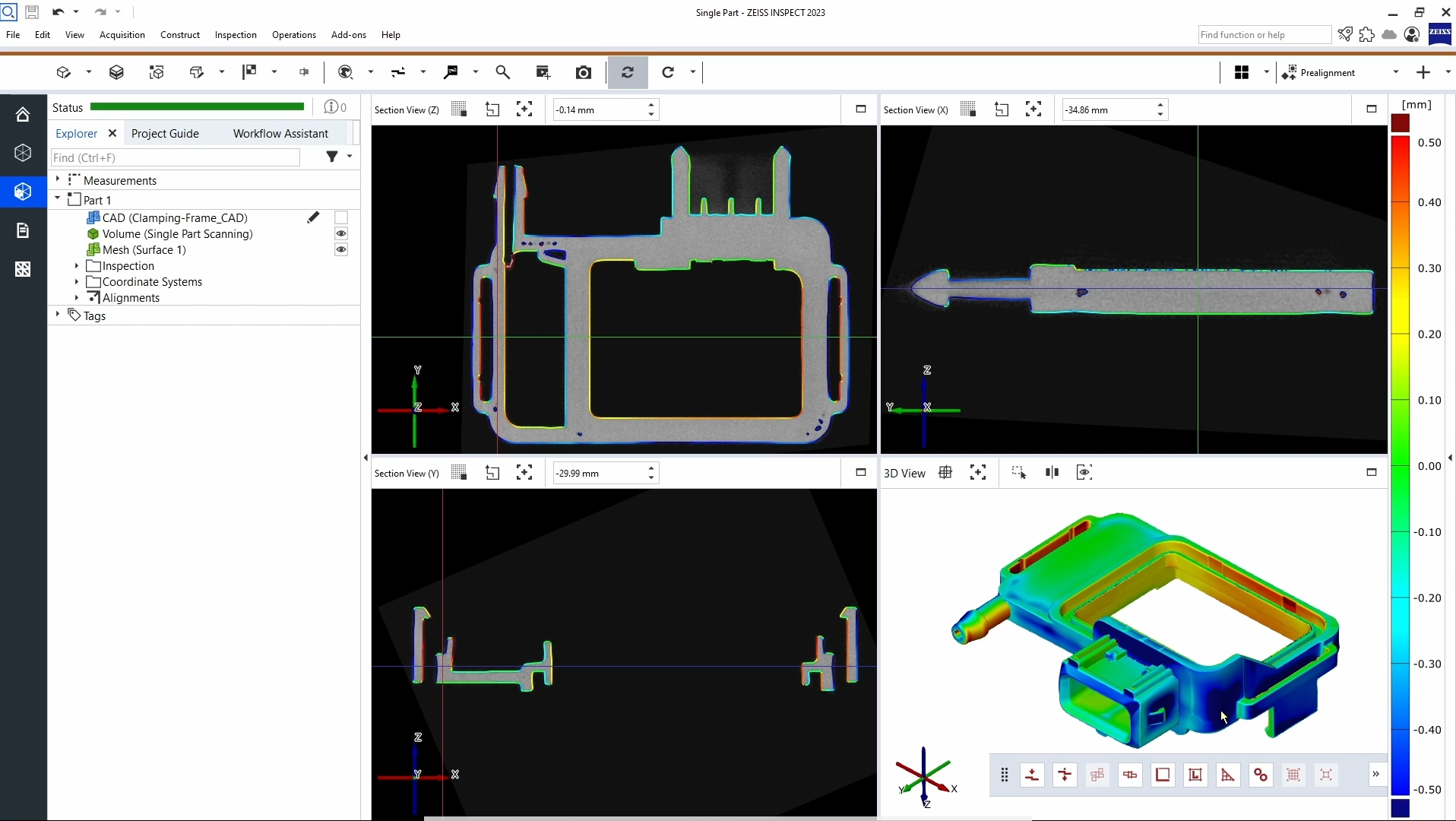

METROTOM 1: Part inspection with CAD data

In this Getting Started Aysel and John will show you how to inspect a 3D scan of your METROTOM 1 using not only scan data but CAD data, too. Find out about the benefits of 3D inspection with CAD data. Discover how to join and align a scan mesh with a CAD file. Learn about the software’s surface comparison, distance inspection and GD&T analysis function. The cherry on top: all inspections are documented in the report workspace – making reporting extra easy.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

Descubra nuestras sesiones de vídeo más recientes

Sesiones

Soluciones

Eventos digitales

Suscribirse a el boletín

- Política De Privacidad

- Aviso Legal

- ©2023. Todos Los Derechos Reservados