Huck Cycles: Quality control of electric motorcycles

Descubra lo que nos impulsa

Precupa: Un futuro más sostenible

Huck Cycles: Quality control of electric motorcycles

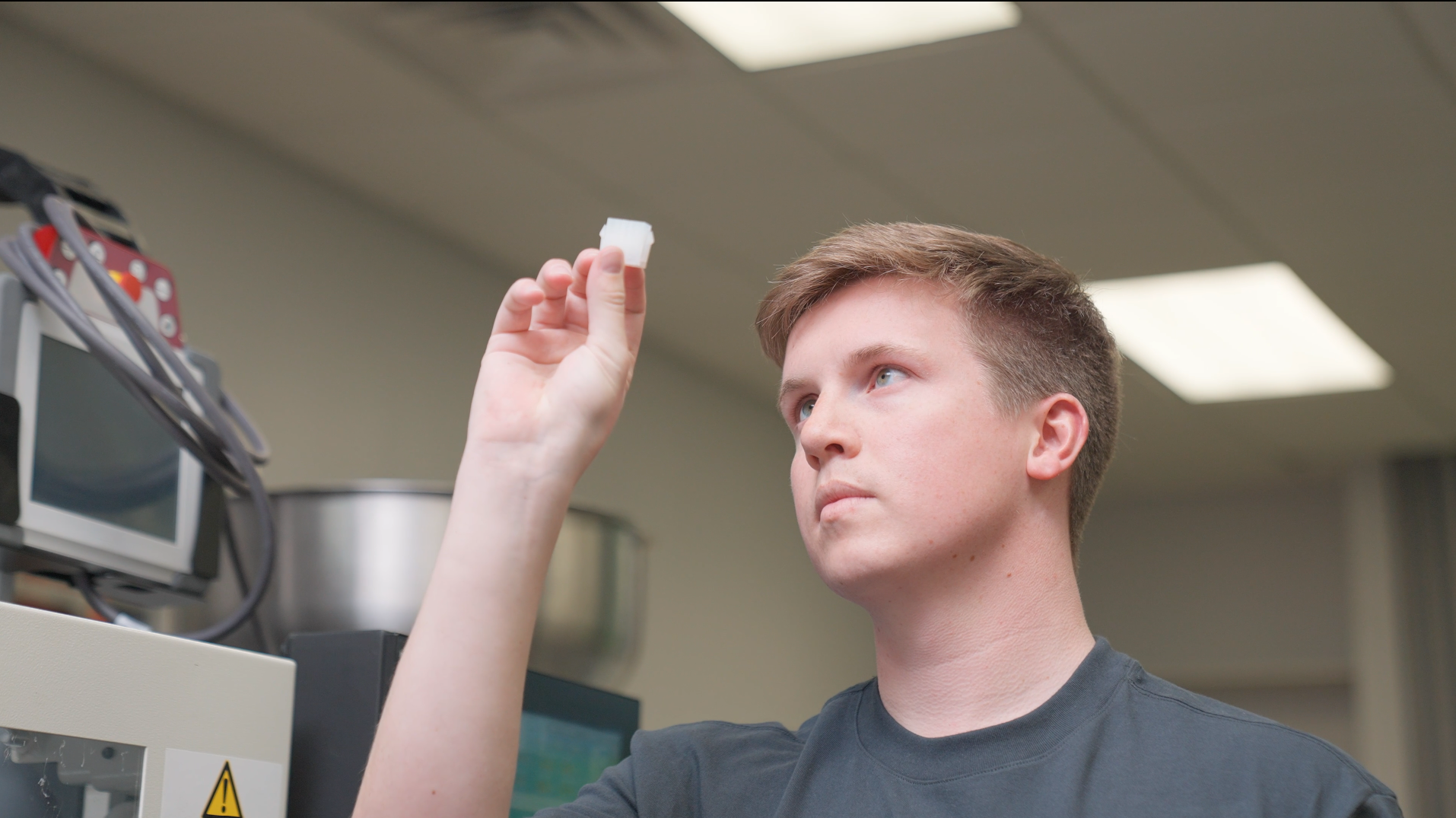

At Huck Cycles it’s all about developing and designing electric motorcycles. The hand-held ZEISS T-SCAN hawk 2 comes into use when exact and fast quality control is needed. With the scanner, controlling each and every single component via a quick scan and CAD comparison is possible – saving the company time and energy, while maintaining high quality motorized vehicles.

Want to learn more about Huck Cycles? Visit www.huckcycles.com

HandsOnMetrology: Dedicated to 3D metrology

Welcome to HandsOnMetrology. We are dedicated to 3D scanning and 3D inspection. We want to excite you about 3D metrology. We want to share knowledge. We want to entertain you with stories about makers. All to support your story. Be part of it.

Precupa: Looking to a more sustainable future

Operating for over 40 years at the foot of the Alps, Bavarian firm Precupa builds injection molds for the plastic industry. Together with his team, managing director Thomas März is constantly looking for ways to incorporate innovative and sustainable new technologies, such as Zeiss Reverse Engineering, into Precupa’s workflow. Our Maker Portraits are behind-the-scenes looks at some of the most exciting manufacturing, maintenance and repair service workshops.

Want to learn more about Precupa? Visit www.precupa.de

Hola

Encuentre inspiración, infórmese sobre el escaneado 3D y la inspección 3D

Sesiones más recientes

METROTOM 1: How to inspect the inside of electronic connector housings

Did you know that the 3D scanner METROTOM 1 is ideal for the overall inspection of electronic connectors housings? Let Alex show you how a simple 3D scan – powered by CT technology – can provide you with valuable data to determine the external and internal part quality.

Do you have any question on our 3D scanners? Contact us via support@HandsOnMetrology.com

Sabelt: High performance seat belts for a safer future

Take a look behind the scenes at Sabelt, the Turin-based international market leader in high performance seat belts and manufacturer of outstandingly good car seats, race suits and other motorsport accessories. Their main goal? To harmonize the three key elements of their business: economic growth, social inclusion and environmental protection. The video shows you what our 3D scanner ZEISS T-SCAN hawk 2 has to do with it. Thanks to our Italian partner Metrologia SpA for sharing this story.

Want to learn more about Sabelt. Visit https://www.sabelt.com/

How to scan large parts using ZEISS T-SCAN hawk 2

Looking for an easy and intuitive way to 3d scan large parts up to multiple meter? Then the 3D laser scanner ZEISS T-SCAN hawk 2 with the new satellite mode is the right solution for you. Let Matthias show you how it’s done.

Do you have any questions about ZEISS T-SCAN hawk 2? Contact us via support@HandsOnMetrology.com

HSB: Maintenance of historic steam locomotives

HSB is the largest service provider for public transportation in eastern Germany. They use the state-of-the-art 3D scanning technology of the ZEISS T-SCAN hawk 2 to ensure that their steam locomotives run non-stop and that their traditional drives are preserved for the future. Accurate 3D models of the machines support the maintenance, repair and overhaul – keeping a part of German history alive in the Harz mountains.

Want to learn more about HSB? Visit https://www.hsb-wr.de/startseite/

Data import from 3rd party scanners

Working with different types of scanners? Well, you only need one software to evaluate your data. In this video, Kai shows you how easy it is to import point cloud data into ZEISS INSPECT, to create a mesh and to start your inspection.

All functions shown are available in the current software version.

Have you got any questions about ZEISS INSPECT? Then contact us via email: support@HandsOnMetrology.com

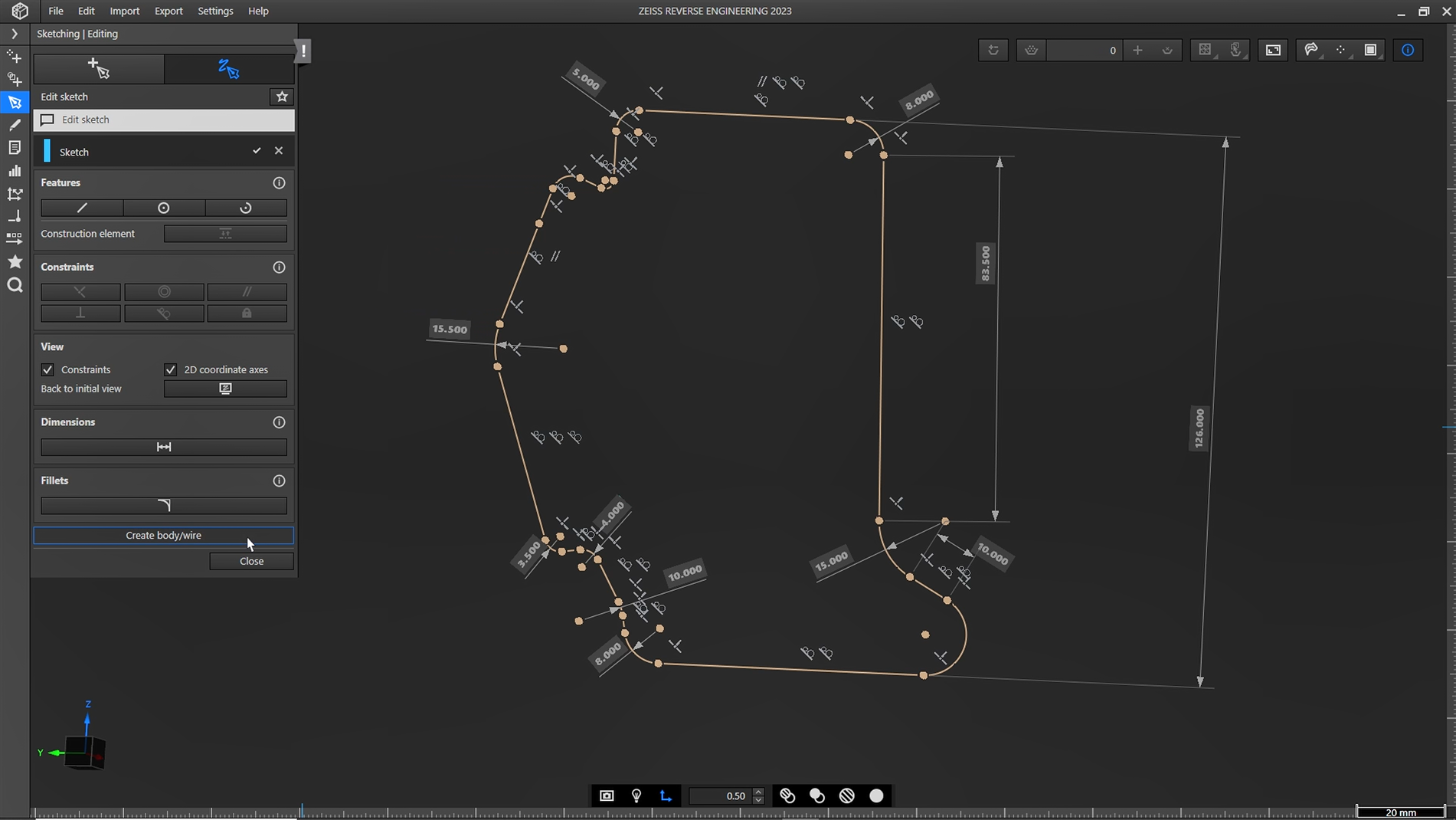

New Sketching function in ZEISS REVERSE ENGINEERING

Looking for an easy way to get more control over your reverse engineered models? With the new sketching function in ZEISS REVERSE ENGINEERING, creating CAD models is easier than ever. Your benefit: fully dimensioned and constrained CAD from scan data.

Do you have any questions about ZEISS REVERSE ENGINEERING? Contact us via support@HandsOnMetrology.com

New videos: One-Minute Insight

Use the Clipping Cube function to get a perfect view

Need to look at a project with a lot of details and obstructed parts? Nanno shows you a trick to get a clear view of just the details you are interested in – by using the Clipping Cube function in ZEISS INSPECT.

All functions shown are available in the current software version.

Have you got any questions about ZEISS INSPECT? Then contact us via email: support@HandsOnMetrology.com

How to save time with Quick GD&T

Get a One Minute Insight from Christine, Carl Zeiss GOM Metrology Braunschweig. She shows you how to save many mouse miles with a single click on “Quick GD&T” to get an extra fast tolerance check. All functions shown are available in the current software version.

Have you got any questions about ZEISS INSPECT? Then contact us via email: support@HandsOnMetrology.com

Data imports from 3rd party scanners

Working with different types of scanners? Well, you only need one software to evaluate your data. In this video, Kai shows you how easy it is to import point cloud data into ZEISS INSPECT, to create a mesh and to start your inspection.

All functions shown are available in the current software version.

Have you got any questions about ZEISS INSPECT? Then contact us via email: support@HandsOnMetrology.com

Le damos la bienvenida al nuevo hogar del escaneado 3D

#HandsOnMetrology es el nuevo recurso para todo lo relacionado con el escaneado 3D. Desde instrucciones de configuración paso a paso hasta tutoriales más avanzados y hacks de expertos: Esta plataforma está hecha para aprender. Para encontrar inspiración. Y para encontrar el apoyo que necesita para ofrecer la excelencia en la digitalización 3D. Esta plataforma se ha creado para usted.

¿Está buscando una

solución de escaneado 3D?

Tema central: Condiciones de escaneado exigentes

Cómo usar un escáner

3D portátil en

producción

How to measure in production

Small and portable: the ZEISS T-SCAN hawk 2 is made for the use in production. See here how it supports your complete process chain from data collection for reverse engineering, different inspection tasks to the digital assembly of produced parts.

Do you want to find out more about the portable 3D laser scanner T-SCAN hawk 2? Visit HandsOnMetrology.com/sessions

Más sesiones

METROTOM 1: Scanning multiple parts

The 3D scanner ZEISS METROTOM 1 – powered by CT technology – is perfect for scanning multiple parts at once, as it seriously reduces scan times. Interested? Then watch Aysel and John’s tutorial. Learn how to prepare the parts for 3D scanning, discover how to set up the software – and experience its simple, built-in separation tool: for separating out the batch volume into smaller volumes for each individual part.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

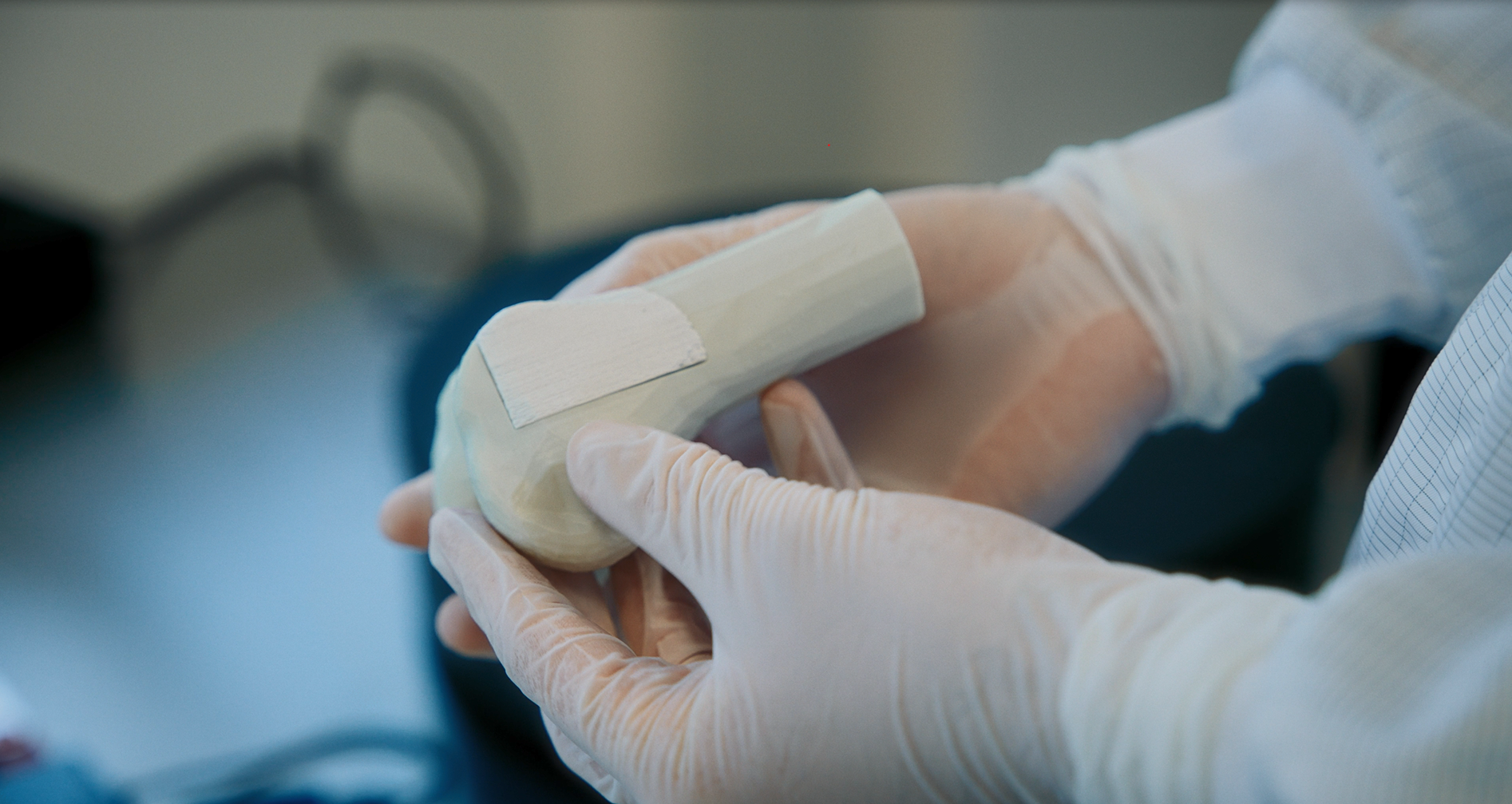

Ossiform: Quality control of 3D printed bone implants

How does satellite mode work and why do you need it

Scanning larger parts can be challenging. We simplified the the process with the new satellite mode of the handheld laser scanner ZEISS T-SCAN hawk 2. It does without coded markers thus preparations are easy and fast. Learn more about the advanced way of photogrammetry here. Got any questions? Contact us via support@HandsOnMetrology.com.

How to use a 3D scanner for dent detection

Looking for a way to speed up and refine your aircraft MRO? Let Roel show you how the ZEISS T-SCAN hawk 2 and the Inspect Software aid in various inspection tasks, like GD&T, CAD comparisons or defect maps. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: All features of the remote control buttons

Let Aysel show you the different possibilities of the control buttons on the back of the T-SCAN hawk 2. It makes starting the remote workflow, zooming in and out, opening the menu and more as easy as a push of the button. Have you got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to use 3D scanning to build up rally cars

Suscríbase a nuestra lista de correo

Sea el primero en conocer las novedades

¿Qué solución de escaneado 3D es la más adecuada para usted?

ZEISS T-SCAN hawk 2

Ligero y extraordinariamente fácil de manejar: Su solución portátil para la precisión metrológica en el escaneado 3D y la inspección 3D.

¿Necesita una

solución de

escaneado 3D?

Cuando lo que importa es el interior

ZEISS METROTOM 1 es sinónimo de facilidad de uso, datos 3D precisos y control de calidad desde afuera hacia adentro.

GOM ATOS Q

GOM Scan 1

GOM Scan 1

Se abren nuevas posibilidades: un escáner 3D compacto, móvil y versátil para mallas precisas y grandes ideas.

ZEISS INSPECT

Haciendo visible la calidad

Sencillo, intuitivo y con un amplio conjunto de funciones de

inspección: descargue el estándar en software de metrología 3D

gratis.

¿Desea más información?

Póngase en contacto con su socio local de #HandsOnMetrology.