Archeology meets 3D Scan-Technology

Museum of Research Schöningen: Archeology meets 3D Scan-Technology

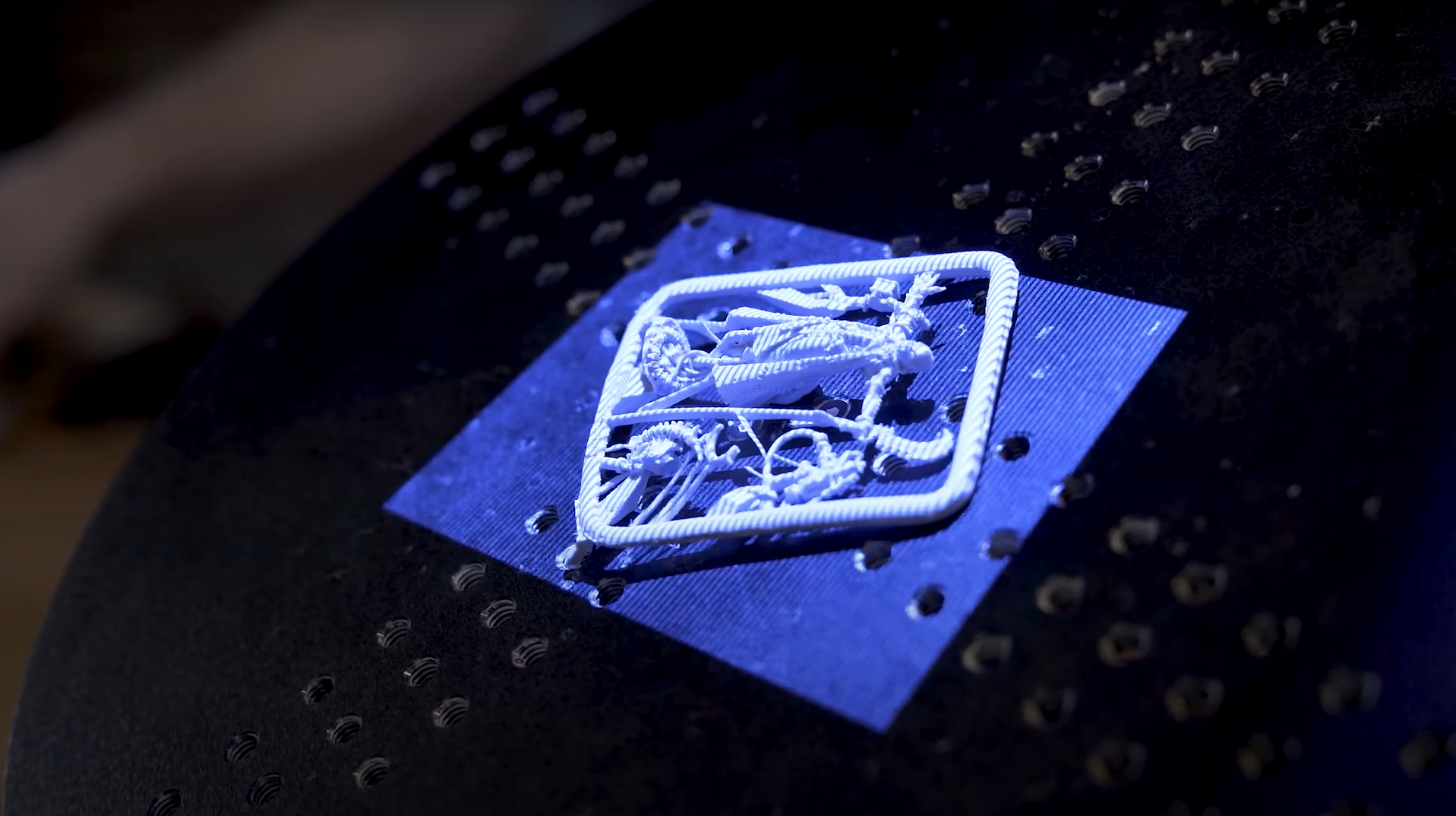

300.000 years of history are archived at the Museum of Research in Schöningen. 3D metrology solutions help to collect detailed information about the findings. Whether the reconstruction of parts or precise surface inspection: Thus the GOM Scan 1 and the software solution allow an insight into the past, which is accessible to everyone. Learn more about the Museum: https://forschungsmuseum-schoeningen.de/home

Sesiones más recientes

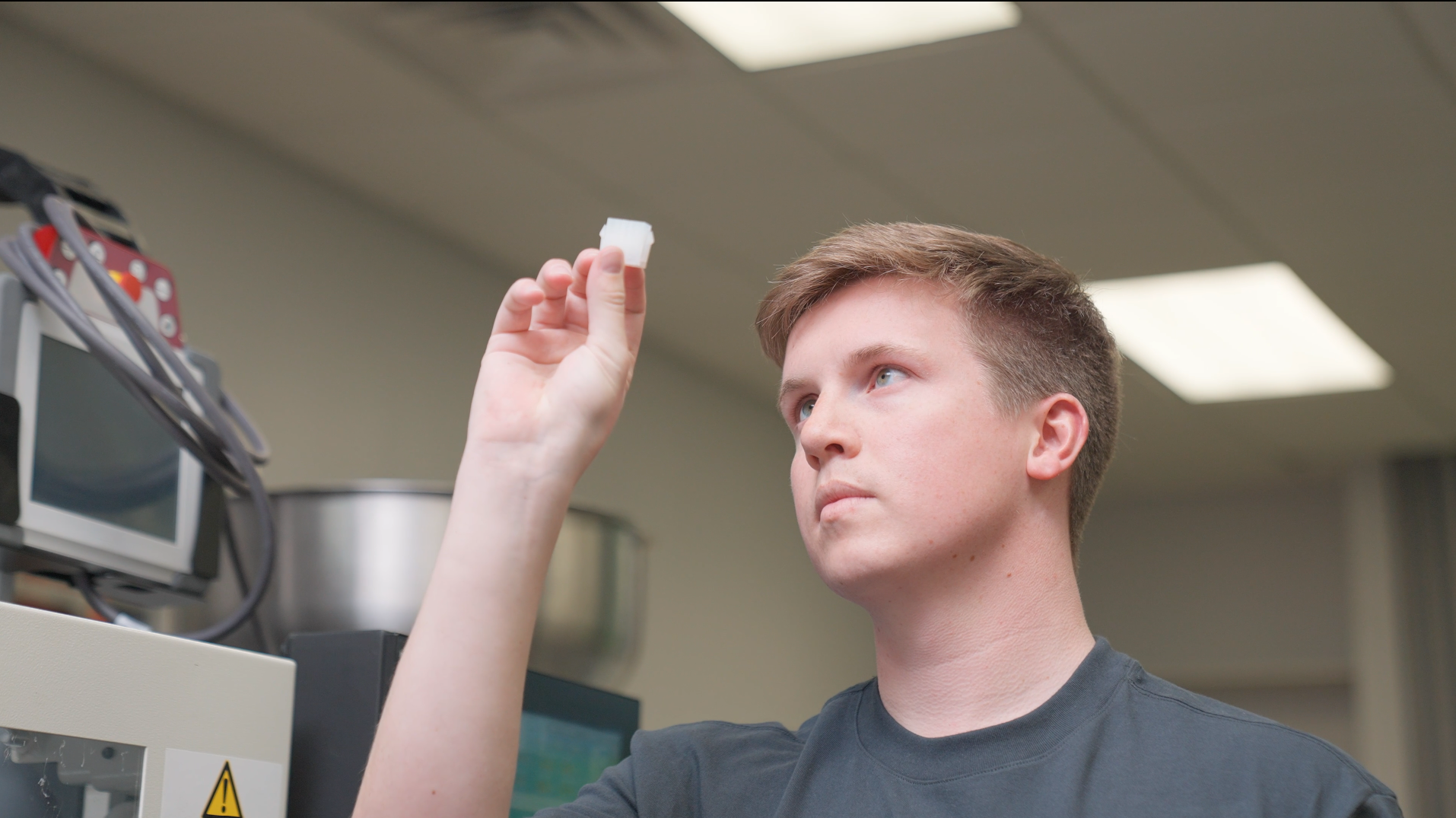

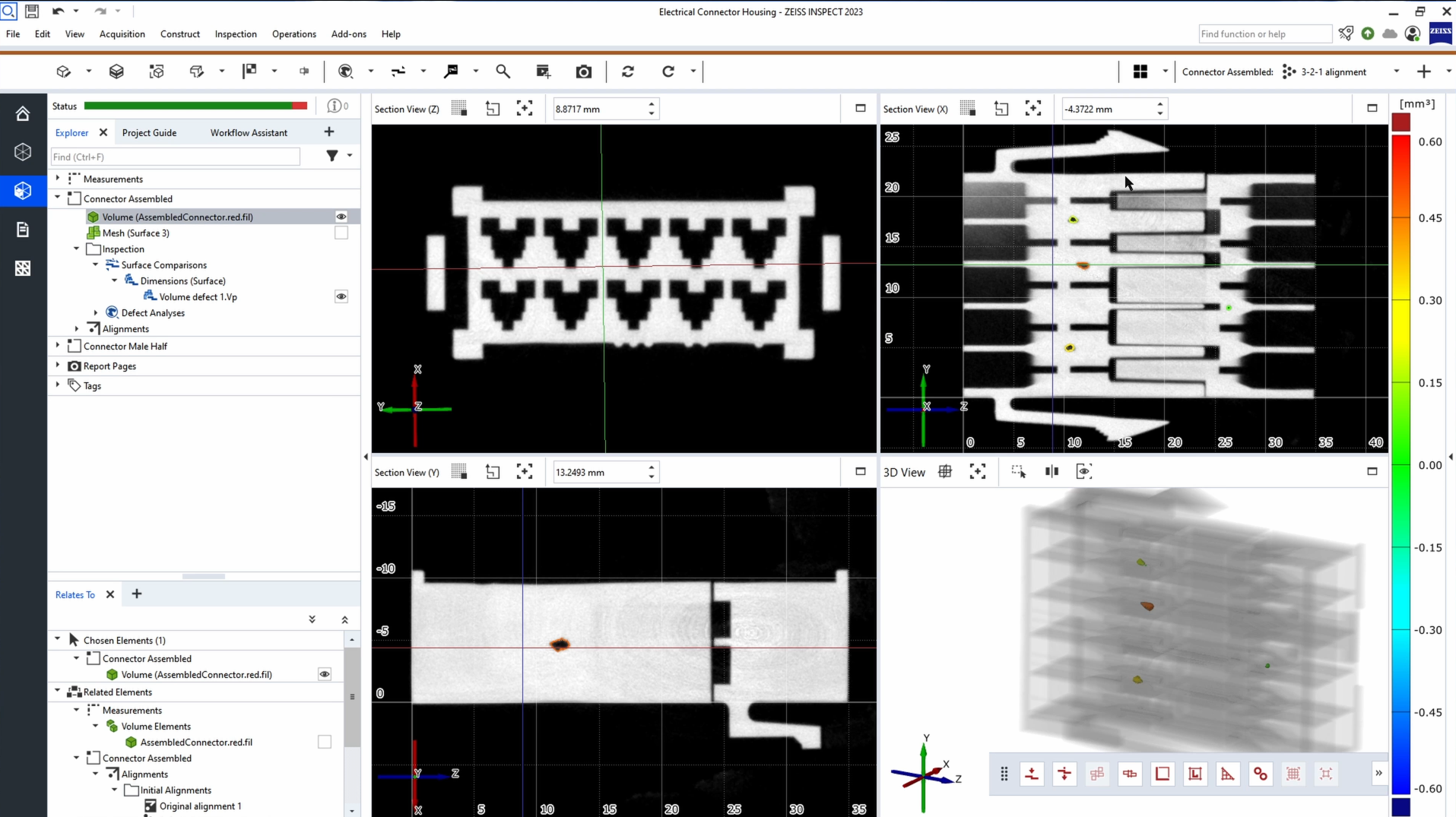

METROTOM 1: How to inspect the inside of electronic connector housings

Did you know that the 3D scanner METROTOM 1 is ideal for the overall inspection of electronic connectors housings? Let Alex show you how a simple 3D scan – powered by CT technology – can provide you with valuable data to determine the external and internal part quality.

Do you have any question on our 3D scanners? Contact us via support@HandsOnMetrology.com

Sabelt: High performance seat belts for a safer future

Take a look behind the scenes at Sabelt, the Turin-based international market leader in high performance seat belts and manufacturer of outstandingly good car seats, race suits and other motorsport accessories. Their main goal? To harmonize the three key elements of their business: economic growth, social inclusion and environmental protection. The video shows you what our 3D scanner ZEISS T-SCAN hawk 2 has to do with it. Thanks to our Italian partner Metrologia SpA for sharing this story.

Want to learn more about Sabelt. Visit https://www.sabelt.com/

How to scan large parts using ZEISS T-SCAN hawk 2

Looking for an easy and intuitive way to 3d scan large parts up to multiple meter? Then the 3D laser scanner ZEISS T-SCAN hawk 2 with the new satellite mode is the right solution for you. Let Matthias show you how it’s done.

Do you have any questions about ZEISS T-SCAN hawk 2? Contact us via support@HandsOnMetrology.com

Lo más popular

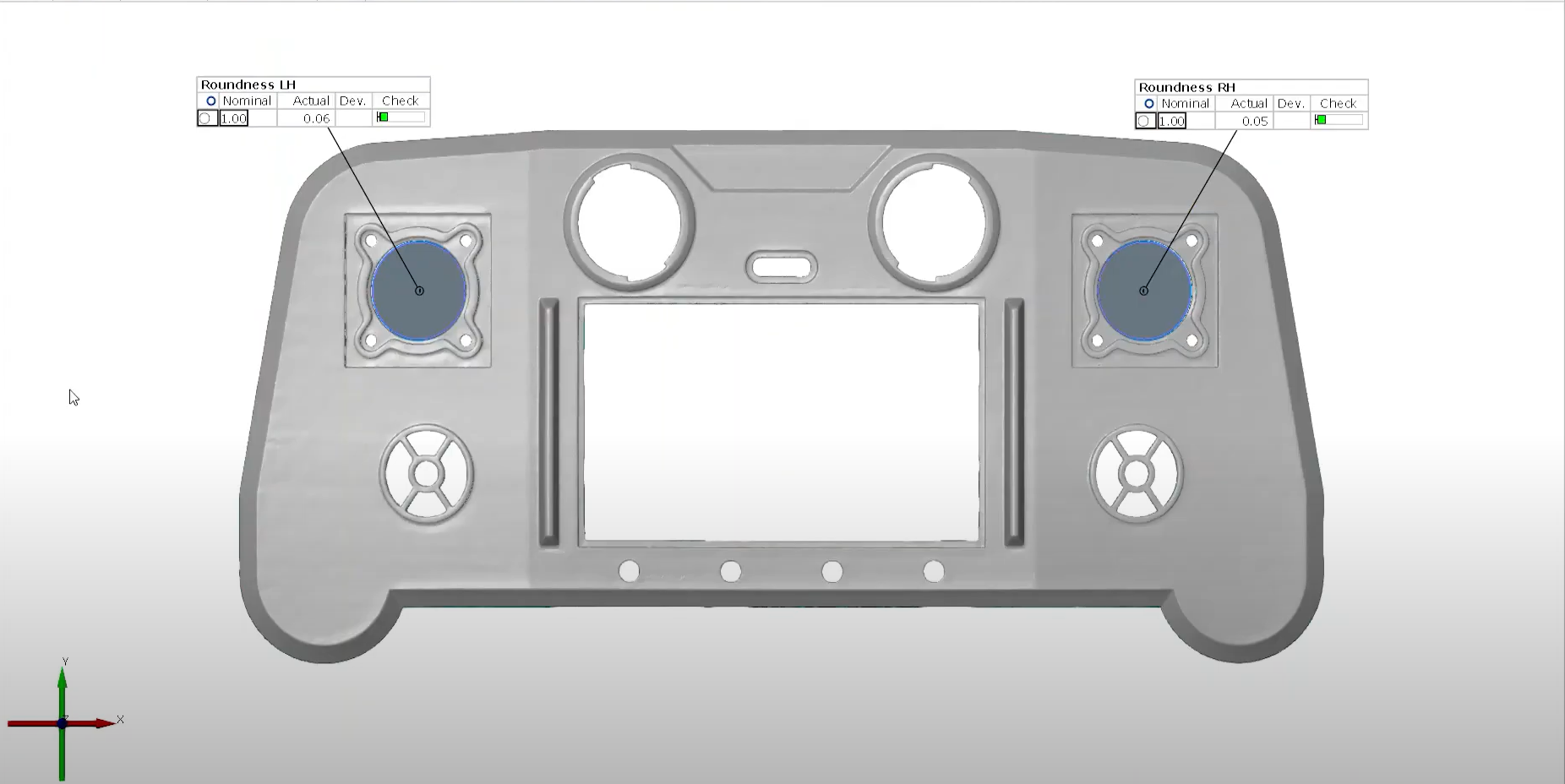

How to use ZEISS INSPECT as a presentation viewer

Get an insight from Jonas and learn why he prefers to use ZEISS INSPECT as a viewer whenever he has to present the results of an inspection job to a client or the team.

All functions shown are available in the current software version.

Have you got any questions about ZEISS INSPECT ? Then contact us via email: support@HandsOnMetrology.com

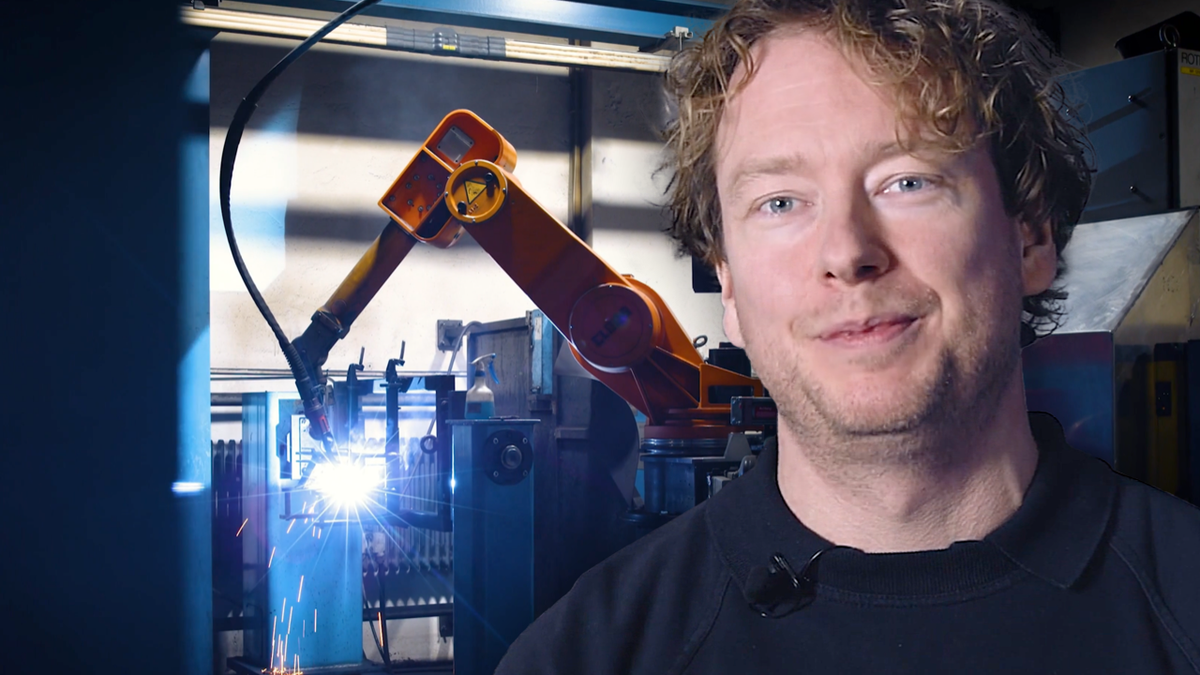

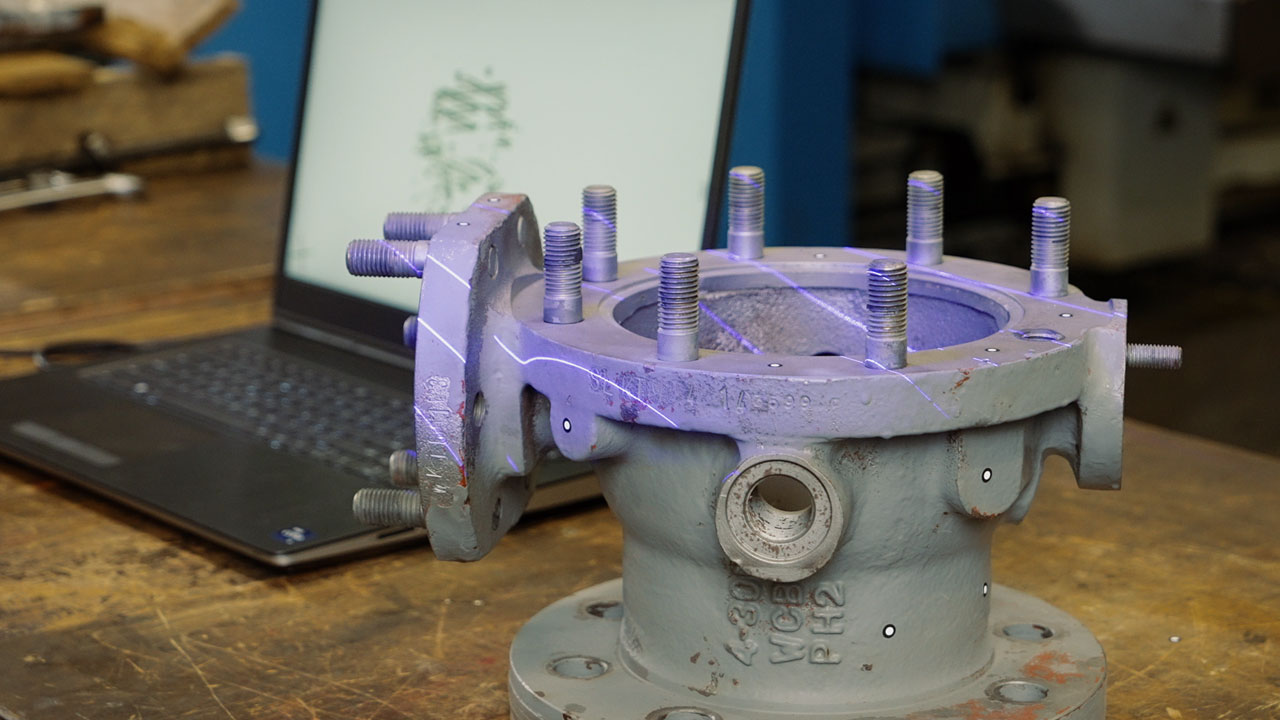

How to 3D scanning for wear control in MRO

Wear and tear of production equipment causes malfunctioning, delays, downtime. In this How to, Roel shows you how 3D scanning is used to implement predictive maintenance – and therefore keep production running efficiently.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: The new Satellite mode

In this Getting Started we demonstrate how to accurately scan large parts with photogrammetry. The new integrated satellite mode ensures precise pre-referencing. No other features, like coded markers, are necessary. Watch the video to see the T-SCAN hawk 2 unleash its full potential.

Do you want to find out more about the portable 3D laser scanner T-SCAN hawk 2? Visit HandsOnMetrology.com/sessions

T-SCAN hawk 2: The setup

Want to know what to consider when setting up your new T-SCAN hawk 2? Let Aysel show you an easy step-by-step guide for starting your laptop as well as the system. Get ready for your first scan with the T-SCAN hawk 2! Have you got any questions about 3D scanning? Contact us via support@HandsOnMetrology.com

How to use a 3D scanner in confined spaces

In this How to Roel is scanning complex and hard to reach areas of a van interior. Whether for inspection or design purposes – the ZEISS T-SCAN hawk 2 is the perfect fit for extracting accurate and complete dimensions in confined spaces. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

Museum of Research Schöningen: Archeology meets 3D Scan-Technology

300.000 years of history are archived at the Museum of Research in Schöningen. 3D metrology solutions help to collect detailed information about the findings. Whether the reconstruction of parts or precise surface inspection: Thus the GOM Scan 1 and the software solution allow an insight into the past, which is accessible to everyone. Learn more about the Museum: https://forschungsmuseum-schoeningen.de/home

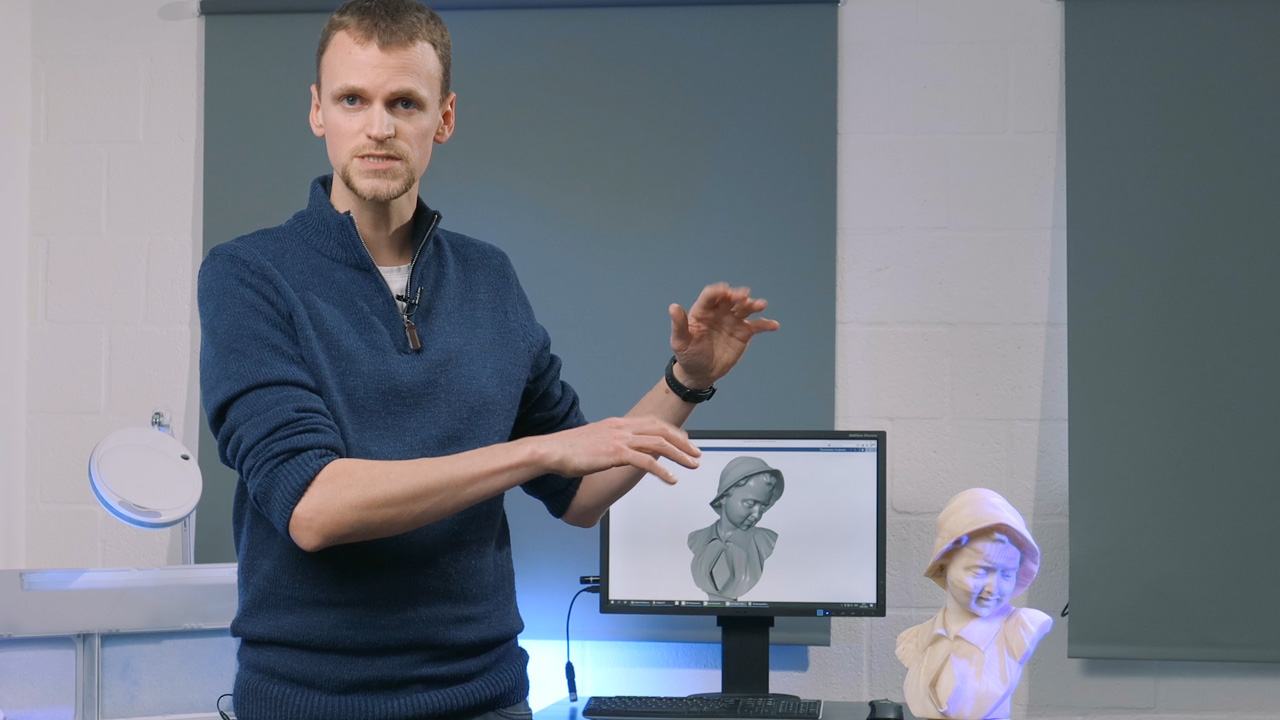

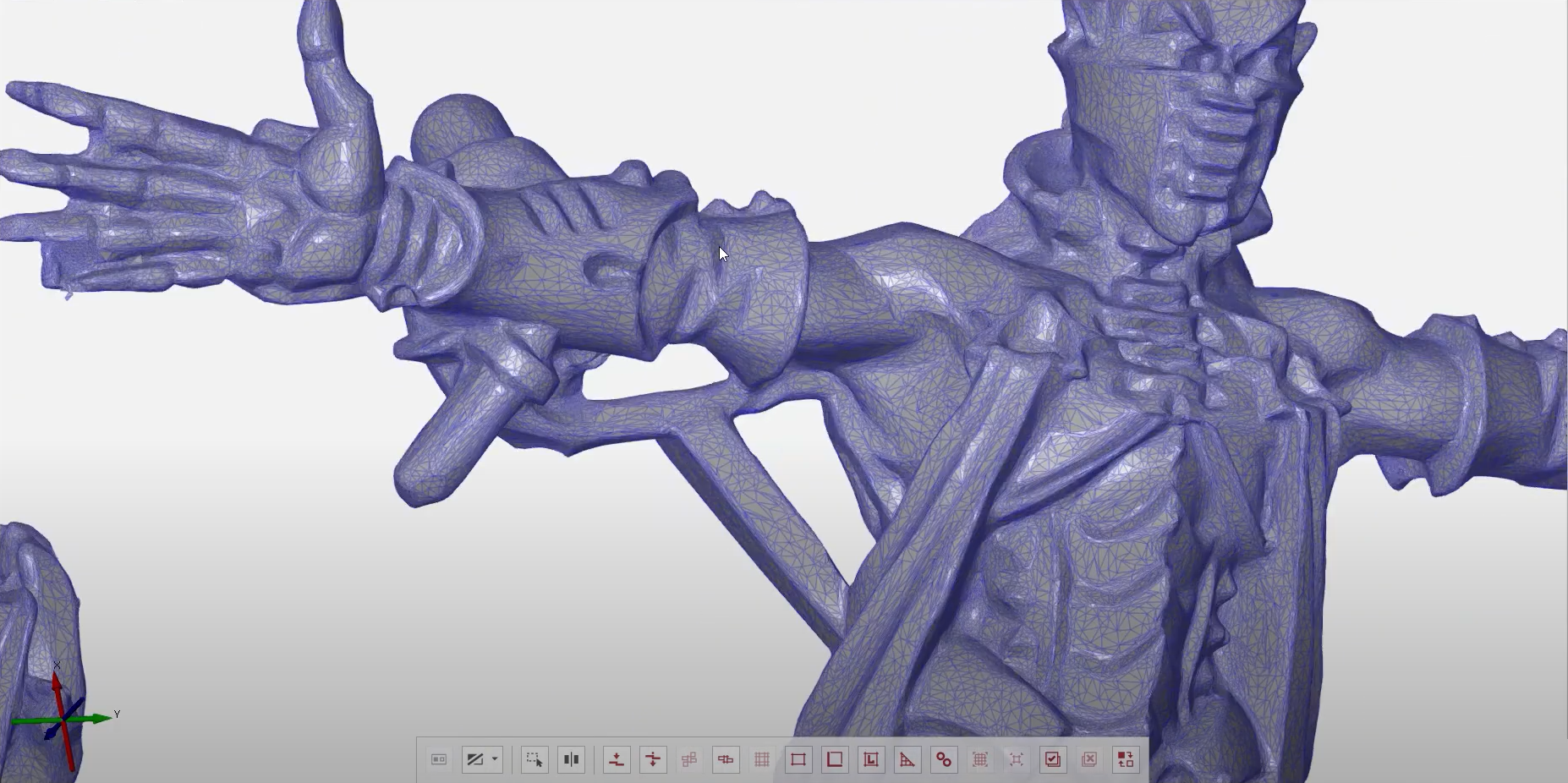

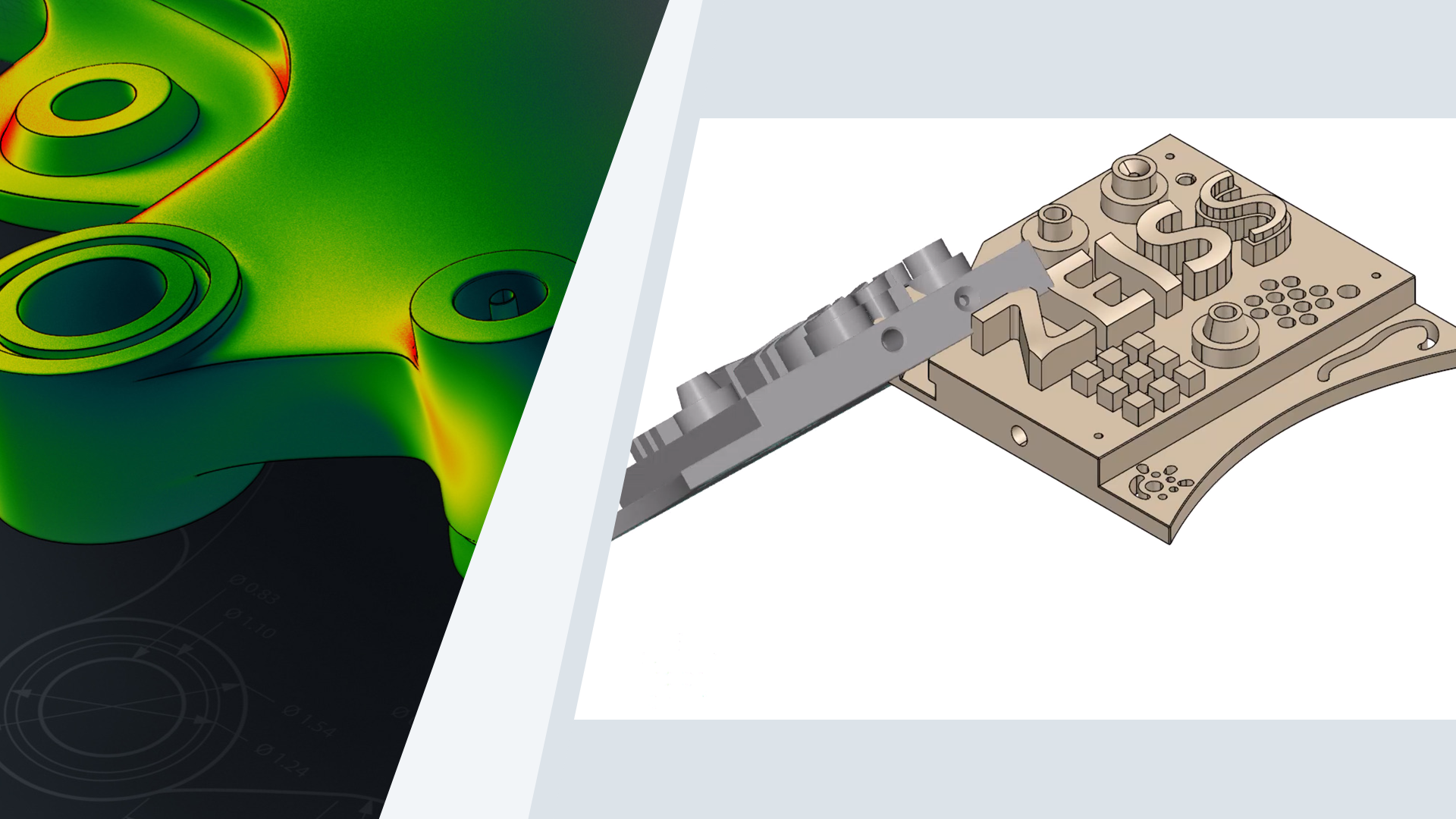

Cutting objects into pieces with Delete by Plane

Do you want to print a piece of art that is bigger than the volume of your 3D printer? Jurgen from Tetra Vision shows you an easy way to do just that, using the Delety by Plane function in ZEISS INSPECT.

All functions shown are available in the current software version

Have you got any questions about ZEISS INSPECT? Then contact us via email: support@HandsOnMetrology.com

ZEISS REVERSE ENGINEERING: Tips and tricks

In this video, Josh lets you in on some handy tips and tricks to help you get started even faster with ZEISS REVERSE ENGINEERING. Learn how to bookmark your favorite functions. Discover how the transparency tool can help you get a better look at specific elements. Learn about how the snapshot tool makes it easy for you to create images for reports. Start using the «fit to screen» icon to get a better view of your part. And minimize clicks by looking at the shortcut list in the user guide.

All functions shown are available in the current software version.

Got any questions on the ZEISS software? Contact us via support@HandsOnMetrology.com

How to scan and reprint broken parts

How to 3D scan objects without reference points

SST Flugtechnik: Aircraft design made in Germany

To Wan Hao from the aircraft design company SST Flugtechnik in Chongqing, China, quality is everything. He loves taking anything a client might want into consideration – even before the first presentation. 3D metrology enables him to get it right – this is his story.

More information about our handheld systems, go to Getting Started T-SCAN hawk 2.

Perfiles de creadores

Sabelt: High performance seat belts for a safer future

Take a look behind the scenes at Sabelt, the Turin-based international market leader in high performance seat belts and manufacturer of outstandingly good car seats, race suits and other motorsport accessories. Their main goal? To harmonize the three key elements of their business: economic growth, social inclusion and environmental protection. The video shows you what our 3D scanner ZEISS T-SCAN hawk 2 has to do with it. Thanks to our Italian partner Metrologia SpA for sharing this story.

Want to learn more about Sabelt. Visit https://www.sabelt.com/

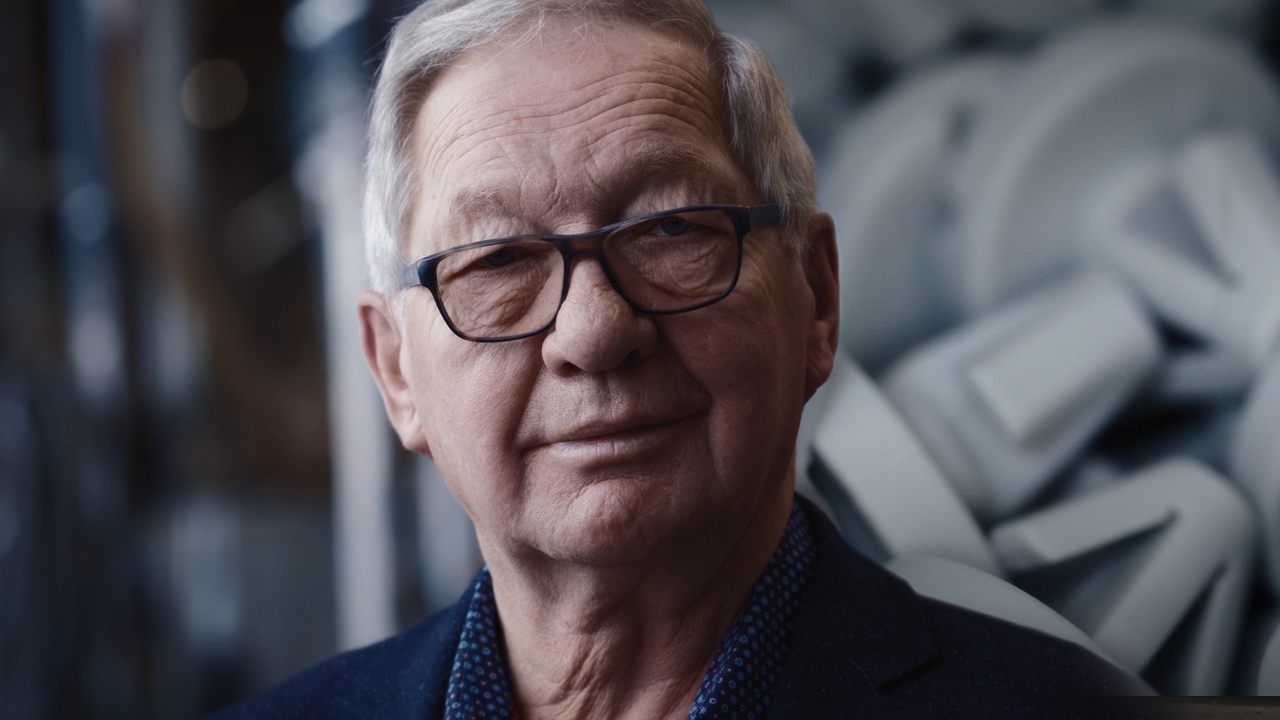

HSB: Maintenance of historic steam locomotives

HSB is the largest service provider for public transportation in eastern Germany. They use the state-of-the-art 3D scanning technology of the ZEISS T-SCAN hawk 2 to ensure that their steam locomotives run non-stop and that their traditional drives are preserved for the future. Accurate 3D models of the machines support the maintenance, repair and overhaul – keeping a part of German history alive in the Harz mountains.

Want to learn more about HSB? Visit https://www.hsb-wr.de/startseite/

Ossiform: Quality control of 3D printed bone implants

Huck Cycles: Quality control of electric motorcycles

At Huck Cycles it’s all about developing and designing electric motorcycles. The hand-held ZEISS T-SCAN hawk 2 comes into use when exact and fast quality control is needed. With the scanner, controlling each and every single component via a quick scan and CAD comparison is possible – saving the company time and energy, while maintaining high quality motorized vehicles.

Want to learn more about Huck Cycles? Visit www.huckcycles.com

Stork: MRO with portable 3D scanner

MRO processes with the portable ZEISS T-SCAN hawk 2 are the way to go for the company Stork.The flexibility of the scanner is ideal for the indiviudal quality control and reverse engineering tasks of their customers. Have a look at the daily work at Stork company in our new Maker Story.

Museum of Research Schöningen: Archeology meets 3D Scan-Technology

300.000 years of history are archived at the Museum of Research in Schöningen. 3D metrology solutions help to collect detailed information about the findings. Whether the reconstruction of parts or precise surface inspection: Thus the GOM Scan 1 and the software solution allow an insight into the past, which is accessible to everyone. Learn more about the Museum: https://forschungsmuseum-schoeningen.de/home

Precupa: Looking to a more sustainable future

Operating for over 40 years at the foot of the Alps, Bavarian firm Precupa builds injection molds for the plastic industry. Together with his team, managing director Thomas März is constantly looking for ways to incorporate innovative and sustainable new technologies, such as Zeiss Reverse Engineering, into Precupa’s workflow. Our Maker Portraits are behind-the-scenes looks at some of the most exciting manufacturing, maintenance and repair service workshops.

Want to learn more about Precupa? Visit www.precupa.de

Fraunhofer IWU: Unique solutions for unique tasks

At the Fraunhofer Intitute for Machine Tolls and Forming Technology, there is no «normal business». Instead, it’s all about unique clients with unique tasks seeking unique solutions. Whether it’s in the automotive, medical or robotics industry: 3D scanning makes it possible to step into the future – every day.

More information about our handheld systems, go to Getting Started T-SCAN hawk 2.

Atka: The plastics specialists

At Atka, it’s all about plastics. And about machines that attach non-manipulable plastic caps to beer kegs and are delivered to breweries all over the world. 3D scanning enables this family-run business to stay ahead of the game at all times.

RLL Racing: Technology wins races

Take a look behind the scenes at Rahal Letterman Lanigan Racing as they are getting their cars ready between races at the IndyCar Series. 3D scanning helps the team to modify their cars’ bodyparts in order to maximize downforce, minimize drag and improve performance.

More information about our handheld systems, go to Getting Started T-SCAN hawk 2.

Formlabs: 3D printing the future

Their goal: to enable anyone to make anything. Meet Sebastian, Head of Operations EMEA at Formlabs Berlin: They build high-quality 3D printers at accessible prices. When it comes to quality control, there’s just no way around 3D scanning – for fast, precise prototypes.

Cowboy: E-bikes for urban riders

Meet Olivier from E-bike manufacturer Cowboy in Brussels. The company’s aim is to manufacture urban mobility solutions that offer amazing design, a seamless usage and affordablity. 3D scanning helps in the creation of perfectly flush frames and in complex assemblies.

Stahlotec: Retrofit for steel colossi

They process steel, aluminium and copper: Stahlotec is not your typical workshop. Open for new ideas, they recently put the focus on sustainability and retrofitting, saving heavy components with mere millimetres of wear from being disposed of: a process that’s only possible with 3D metrology.

Our Maker Portraits are behind-the-scenes looks at some of the most exciting manufacturing, maintenance and repair service workshops. Do you want to learn more about Stahlotec? Visit www.stahlotec.de

fischer group: Innovative tube processing

fischer group is a global supplier for stainless steel tubing. Inhale the scent of metal in the air and see how 3D measurement is an essential part of their workflow – ranging from deviation detection to evaluation and innovation. Check out their story.

Our Maker Portraits are behind-the-scenes looks at some of the most exciting manufacturing, maintenance and repair service workshops. Do you want to learn more about fischer group? Visit www.fischer-group.com

From strip to rebuild: Rally car prep by BMA Autosport

Meet Martin from BMA Autosport in Belgium: His car workshop converts street cars into modern rally cars and historical racing vehicles. After stripping a car down to its bare body shell the BMA team redesigns it into a real hot rod by using 3D models.

Our Maker Portraits are behind-the-scenes looks at some of the most exciting manufacturing, maintenance and repair service workshops. Do you want to learn more about BMA Autosport? Visit www.bma-autosport.com

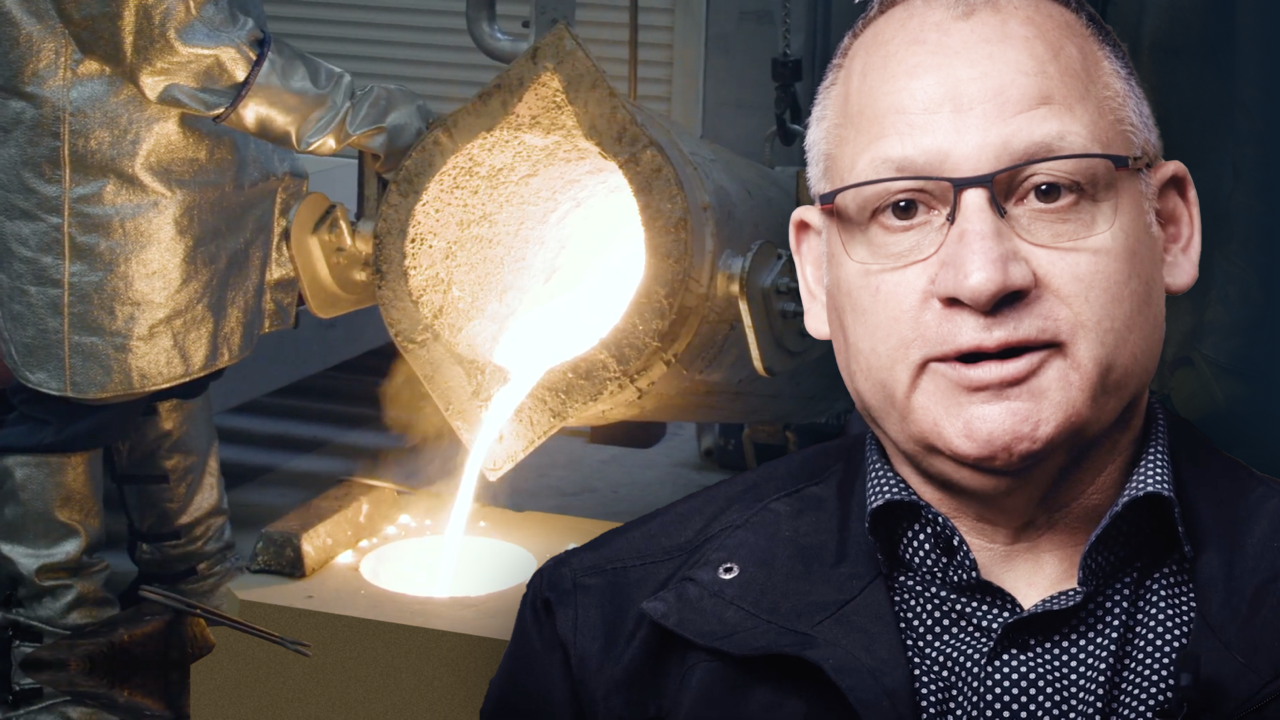

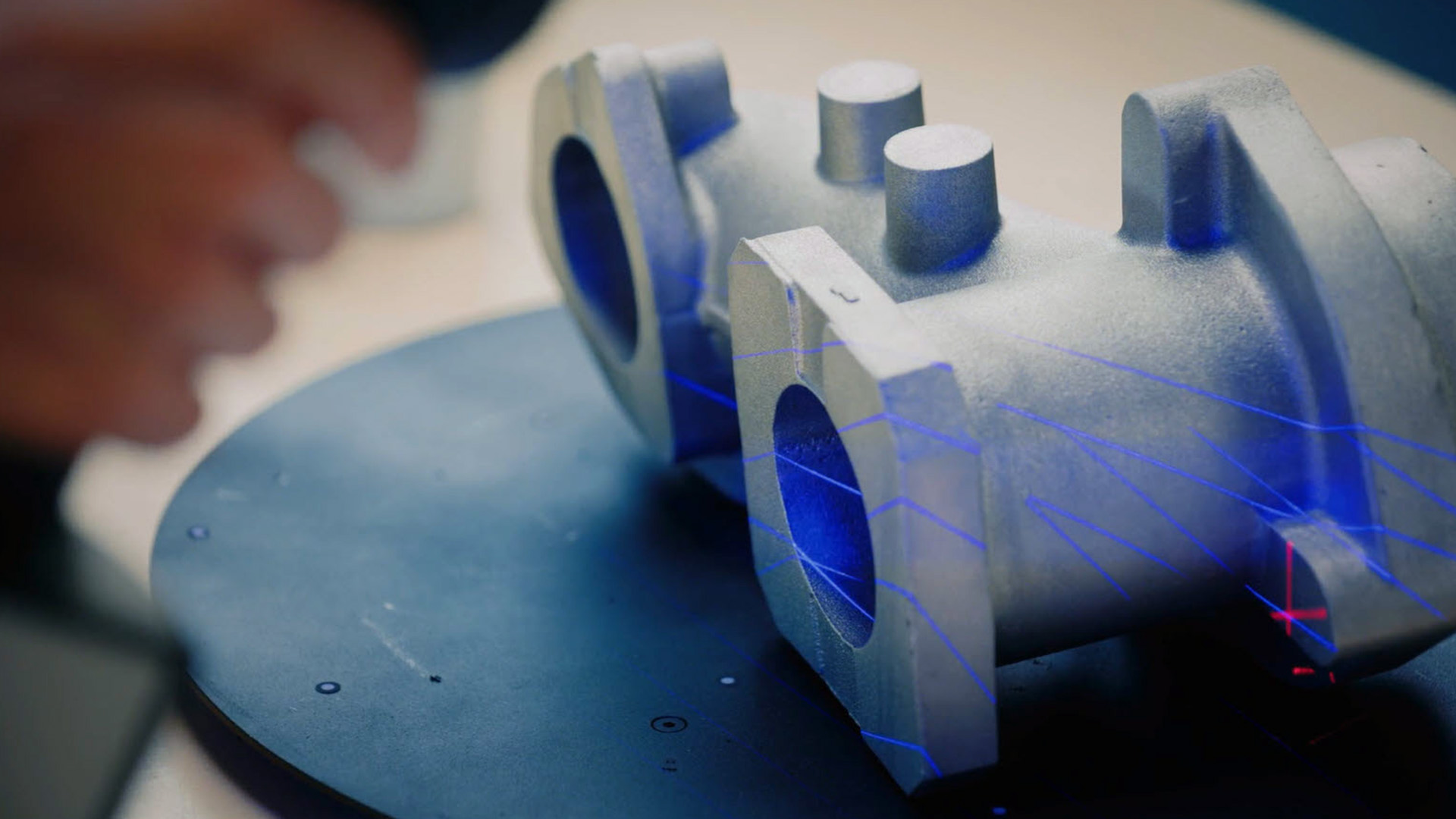

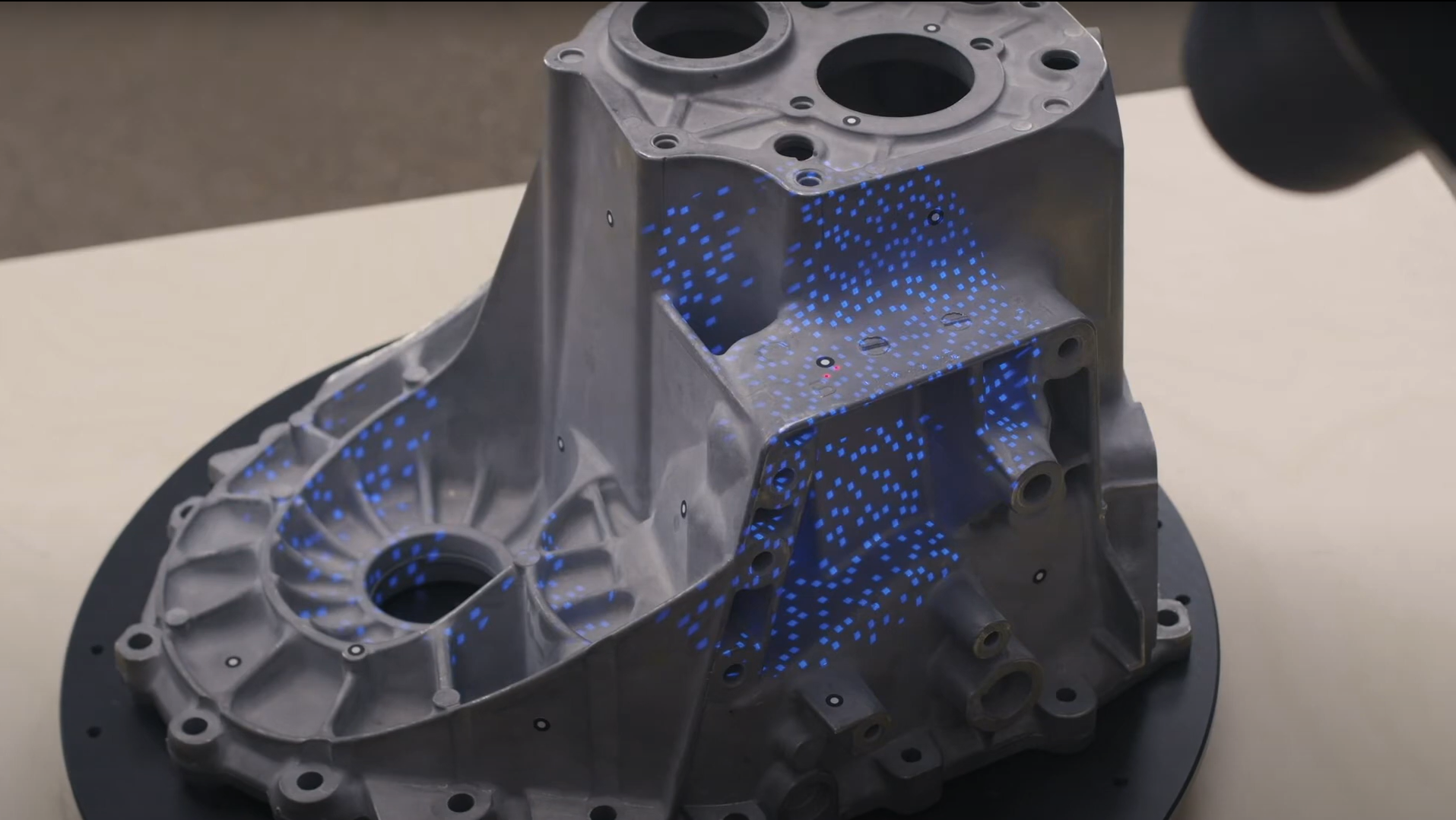

HA Group: The future of foundry (ATOS & Scan Hawk)

Take a look at the Center of Competence at Hüttenes-Albertus. Specialized in foundry engineering, it’s a platform to test new ideas and provide a complete prototyping service. Increasing requirements by clients are met with 3D scanning and 3D inspection.

Our Maker Portraits are behind-the-scenes looks at some of the most exciting manufacturing, maintenance and repair service workshops. Do you want to learn more about Hüttenes-Albertus? Visit www.ha-group.com

More information about our handheld systems, go to Getting Started T-SCAN hawk 2.

R.A.R. Antwerp: Good is never good enough

Welcome to Raymond’s Aircraft Restoration, where Raymond and his son Tim restore and maintain vintage aircrafts. Get a glimpse of their passion for their craft and their deep dedication to quality and precision – assisted by 3D scanning to reproduce missing parts.

Our Maker Portraits are behind-the-scenes looks at some of the most exciting manufacturing, maintenance and repair service workshops. Do you want to learn more about Raymond’s Aircraft Restauration? Visit www.rar.be

More information about our handheld systems, go to Getting Started T-SCAN hawk 2.

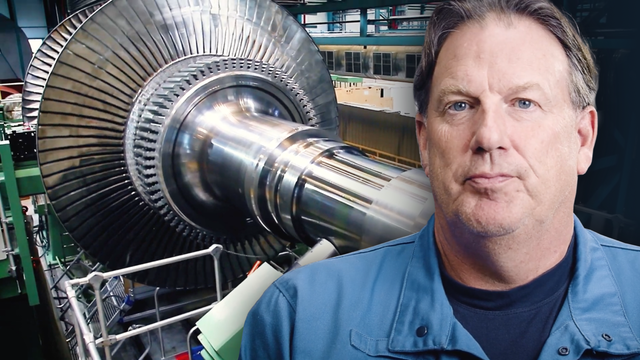

Energetic: The magic of turbine machinery

Meet Johan, director of Energetic Machinery in Belgium, and his passion for industrial steam turbines. The successful implementation of reverse engineering at his company allows Energetic to offer customers a complete service. Check out their story.

Our Maker Portraits are behind-the-scenes looks at some of the most exciting manufacturing, maintenance and repair service workshops. Do you want to learn more about Energetic Machinery? Visit www.energeticmachinery.com

Fagus: Lasts for the international footwear industry

Since 1922, the Fagus factory in Alfeld is all about shoe lasts: the core piece in shoe manufacturing. Andreas Koch scans and measures the wooden lasts for further processing. The final result: green plastic lasts, equipped with everything the shoe manufacturer needs.

MMG: Meet the world’s largest ship propellers

Meet MMG and their impressive ship propellers. Although huge, the parts are planned to the detail before months of development culminate in about ten minutes of casting time. To ensure quality and functionality, 3D measurement plays an import role in the process. Be ready for a big story.

Our Maker Portraits are behind-the-scenes looks at some of the most exciting manufacturing, maintenance and repair service workshops. Do you want to learn more about MMG? Visit www.xxl-metalworking.com

SST Flugtechnik: Aircraft design made in Germany

To Wan Hao from the aircraft design company SST Flugtechnik in Chongqing, China, quality is everything. He loves taking anything a client might want into consideration – even before the first presentation. 3D metrology enables him to get it right – this is his story.

More information about our handheld systems, go to Getting Started T-SCAN hawk 2.

One-Minute Insights

One 3D scan is all you need for precision

You’re new to 3D scanning? You think that scanning across the same area several times igenerates better data? It’s a typical scanning rookie misconception, says Marco, and one that can be easily avoided. One scan is all you need for perfect results.

Have you got any questions about 3D scanning? Then contact us via email: support@HandsOnMetrology.com

ZEISS INSPECT: Less mouse miles with a customized toolbar

Learn how to reduce your mouse mileage by customizing your toolbar. You want to use the software for reverse engineering? Daniel suggests adding Select Patch, Close Holes and Export STL to your bar – for a more intuitive, faster 3D scanning workflow.

All functions shown are available in the current software version.

Do you have any questions about ZEISS INSPECT? Contact us via email: support@HandsOnMetrology.com

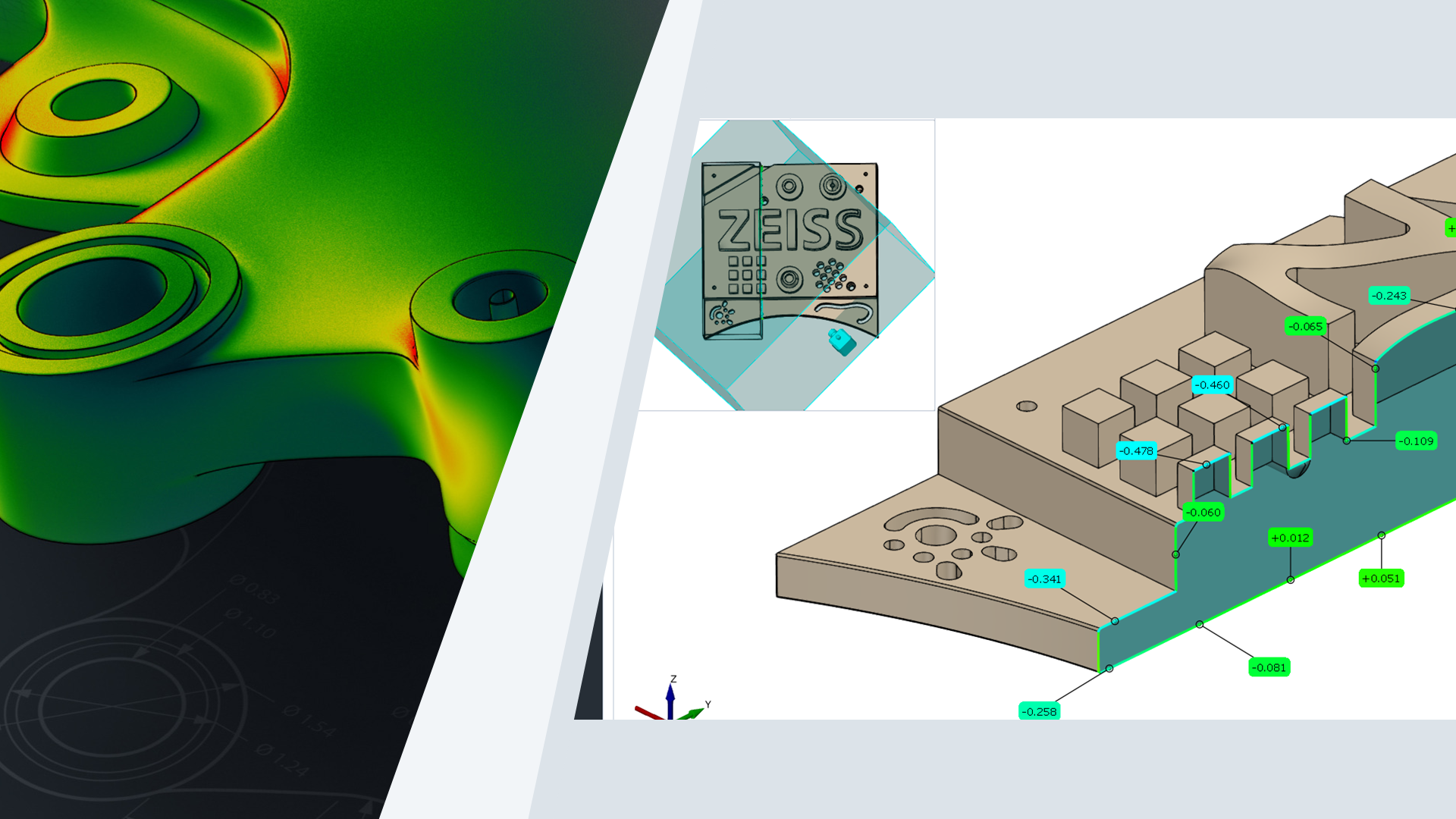

How to use ZEISS INSPECT as a presentation viewer

Get an insight from Jonas and learn why he prefers to use ZEISS INSPECT as a viewer whenever he has to present the results of an inspection job to a client or the team.

All functions shown are available in the current software version.

Have you got any questions about ZEISS INSPECT ? Then contact us via email: support@HandsOnMetrology.com

Cutting objects into pieces with Delete by Plane

Do you want to print a piece of art that is bigger than the volume of your 3D printer? Jurgen from Tetra Vision shows you an easy way to do just that, using the Delety by Plane function in ZEISS INSPECT.

All functions shown are available in the current software version

Have you got any questions about ZEISS INSPECT? Then contact us via email: support@HandsOnMetrology.com

Visualize 3D deviation using isolines

You want to see exactly which areas of a 3D scan are in and out of tolerance? Discover deviations at a glance – by doing a surface comparison and using your 3D scanner to project the isolines directly onto the part. Have you got any questions about 3D scanning? Then contact us via email: support@HandsOnMetrology.com

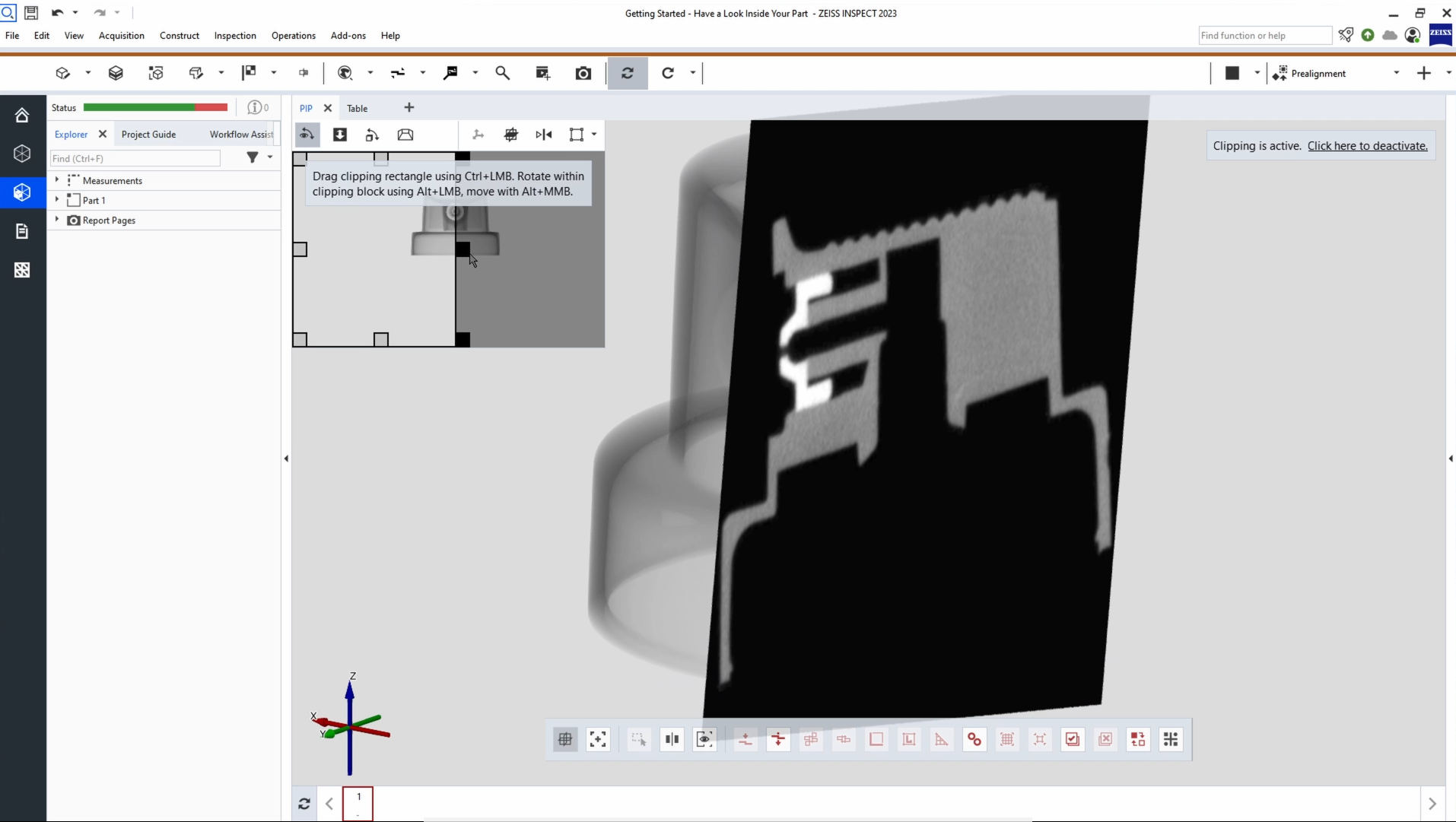

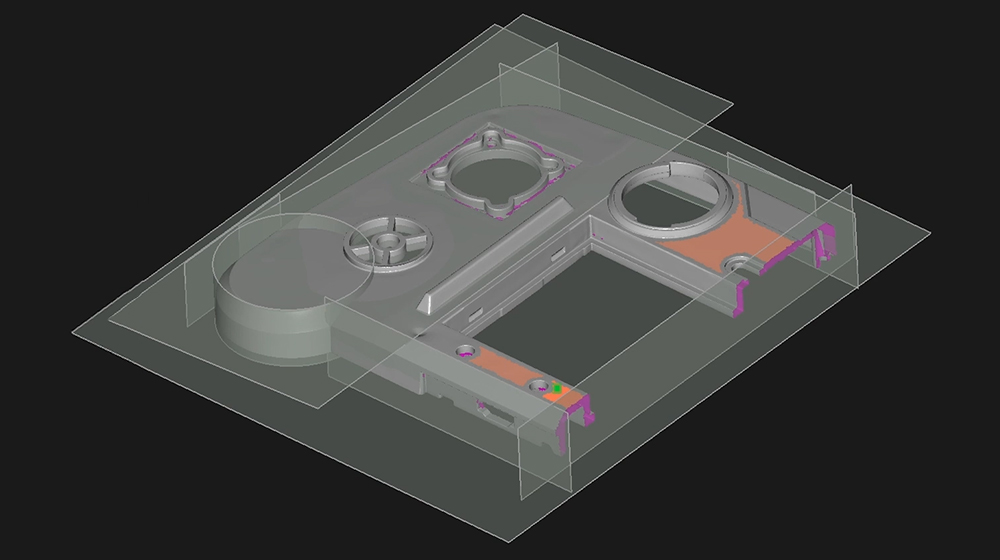

Use the Clipping Cube function to get a perfect view

Need to look at a project with a lot of details and obstructed parts? Nanno shows you a trick to get a clear view of just the details you are interested in – by using the Clipping Cube function in ZEISS INSPECT.

All functions shown are available in the current software version.

Have you got any questions about ZEISS INSPECT? Then contact us via email: support@HandsOnMetrology.com

How to save time with Quick GD&T

Get a One Minute Insight from Christine, Carl Zeiss GOM Metrology Braunschweig. She shows you how to save many mouse miles with a single click on “Quick GD&T” to get an extra fast tolerance check. All functions shown are available in the current software version.

Have you got any questions about ZEISS INSPECT ? Then contact us via email: support@HandsOnMetrology.com

Data import from 3rd party scanners

Working with different types of scanners? Well, you only need one software to evaluate your data. In this video, Kai shows you how easy it is to import point cloud data into ZEISS INSPECT, to create a mesh and to start your inspection.

All functions shown are available in the current software version.

Have you got any questions about ZEISS INSPECT? Then contact us via email: support@HandsOnMetrology.com

3D scan like a pro without a rotation table

You’re starting out in 3D scanning and don’t have a rotation table (yet)? Don’t worry. Follow Daniel’s easy approach to scanning without one: Simply scan the part in eight steps, turning it by 45° between each scan.

All functions shown are available in the current software version.

Have you got any questions about 3D scanning? Then contact us via email: support@HandsOnMetrology.com

Reduce mouse miles with the Smart Creation button

Some 3D inspection projects involve creating a lot of elements – and a lot of mouse miles. Avoid moving your mouse to «Create» over and over again by using the Smart Creation button directly under your mouse pointer.

All functions shown are available in the current software version.

Have you got any questions about GOM Inspect? Then contact us via email: support@HandsOnMetrology.com

How to scan large objects with the new satellite mode

How does satellite mode work and why do you need it

Scanning larger parts can be challenging. We simplified the the process with the new satellite mode of the handheld laser scanner ZEISS T-SCAN hawk 2. It does without coded markers thus preparations are easy and fast. Learn more about the advanced way of photogrammetry here. Got any questions? Contact us via support@HandsOnMetrology.com.

GOM Scan 1

GOM Scan 1: Unboxing

GOM Scan 1: The setup

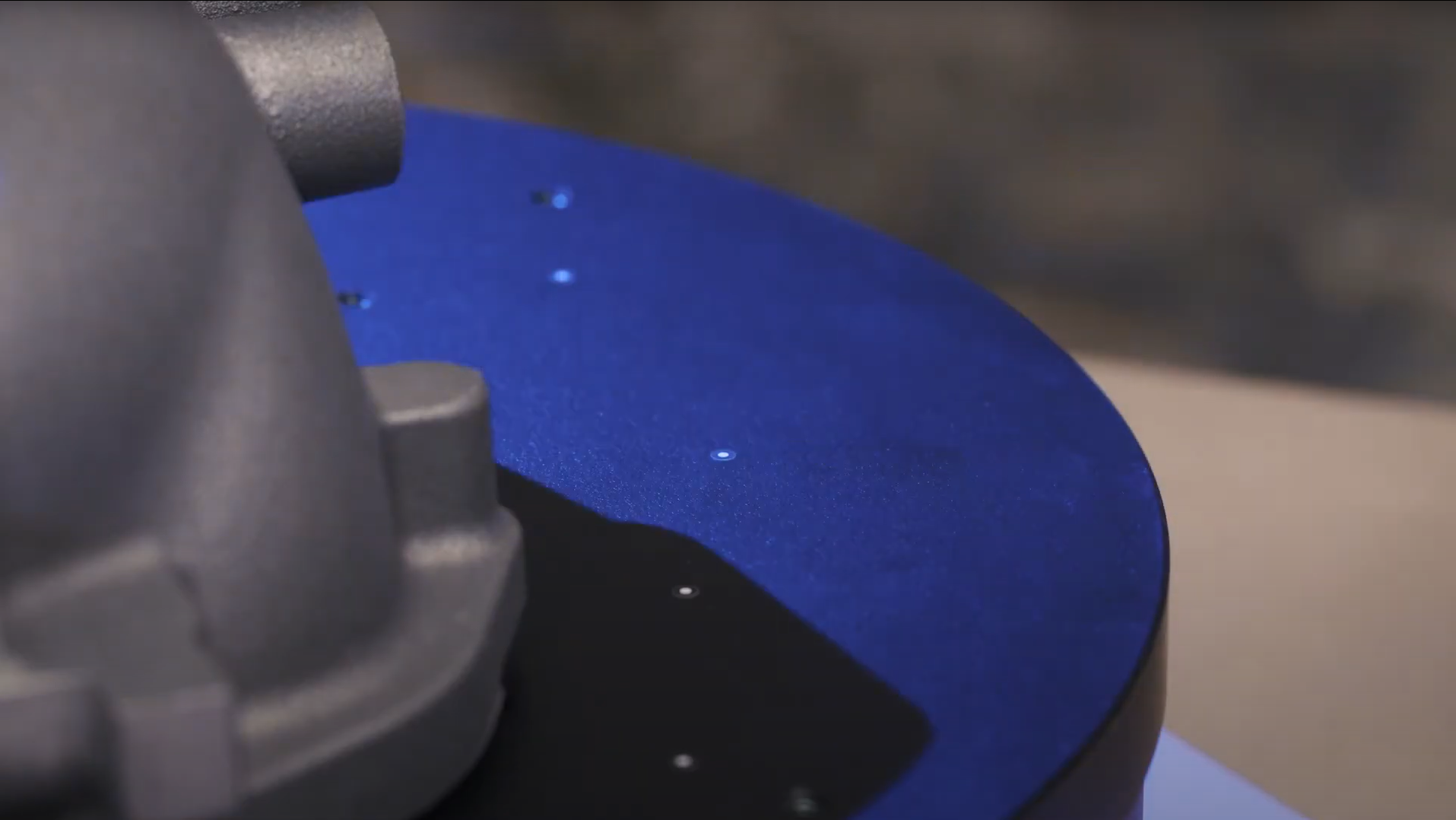

Discover how to scan a part with the new GOM Scan 1 using a manual measuring plate. The distance radar makes finding the correct stand-off distance super easy. Scanning can be done with or without reference points – either way, you get a precise mesh of the part.

GOM Scan 1: Calibration

GOM Scan 1: Select the right sensor for your application

GOM Scan 1: Your first use of ZEISS INSPECT

Let Miles guide you through your first use of ZEISS INSPECT with your new GOM Scan 1. It’s so easy to navigate the start screen and choose the correct workspace. Select the digitize workspace to can start scanning straight away – and get fast, precise results.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via email: support@HandsOnMetrology.com

GOM Scan 1: Introduction to part inspection

GOM Scan 1: Scanning Multiple Parts

GOM Scan 1 for reverse engineering and 3D printing

GOM Scan 1: Scan a part with high levels of detail

Discover how to capture the highest possible detail with the GOM Scan 1, using a sensor with a 100 mm field of view. When scanning a small part, best results are achieved with a desk stand. The result: a detailed mesh that’s ready for 3D printing or reverse engineering.

GOM Scan 1: Measure both sides of an object

Capturing all sides of an object has never been easier. Let Miles show you how to measure a part from the top and from the bottom using a rotary table and the new GOM Scan 1. The result: a highly detailed mesh and perfect digital twin of the object you’ve scanned.

GOM Scan 1: Measure with a rotation table

Learn how easy and fast it is to scan a part with the new GOM Scan 1 using an automatic rotation table. Just choose the right template, define the number of rotations and start scanning – you can watch the data building up on the screen as you go along.

GOM Scan 1: Measure with a measuring plate

Discover how to scan a part with the new GOM Scan 1 using a manual measuring plate. The distance radar makes finding the correct stand-off distance super easy. Scanning can be done with or without reference points – either way, you get a precise mesh of the part.

How to 3D scan different materials

How to 3D scan with the right distance to object

How to find your perfect exposure time with ZEISS INSPECT

Let Norman show you how to find the perfect exposure time for your part. The live camera image in ZEISS INSPECT offers multiple options of automatic exposure times: automatic by matrix computes up to three different exposure times for the entire field of view – making it a good choice for parts that combine light and dark surfaces. Other options: automatic by spot, automatic for reference points and interactive. Take a pick and start scanning!

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to scan and reprint broken parts

How to inspect your 3D print with metrology

T-SCAN hawk 2

T-SCAN hawk 2: Unboxing your new 3D laser scanner

Get started with your T-SCAN hawk 2. In this first episode you get to unbox the new hand-held laser scanner together with Aysel. Whether the power cable, the calibration panel or reference points, we got you covered for easy, fast and precise 3D scanning. Have you got any questions about 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: The setup

Want to know what to consider when setting up your new T-SCAN hawk 2? Let Aysel show you an easy step-by-step guide for starting your laptop as well as the system. Get ready for your first scan with the T-SCAN hawk 2! Have you got any questions about 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Your first use of ZEISS INSPECT

In our Getting Started we demonstrate how easy it is to start scanning with the T-SCAN hawk 2. Besides the calibration process, Aysel navigates you through the ZEISS INSPECT software and gives useful tips and tricks for your first scan.

All functions shown are available in the current software version.

Have you got any questions about 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Scanning in ZEISS INSPECT

Have a look at the remote workflow which guides you through different scanning task with ease. Aysel applies the common scanning strategy of scanning one side of the part only. The buttons on the backside of the scanner simplify the process, even when scanning deep pockets.

All functions shown are available in the current software version.

Got a question? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Scanning with reference points

Have a look at how to easily scan both sides of your part using reference points. With just a push of a button on the T-SCAN hawk 2, the guided workflow assists in the scan. The software optimizes the polygonization of the final mesh. Have you got any questions about 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Scanning without reference points

You are scanning a lot of 3D geometries? Then go ahead and try the scanning strategy Aysel presents in this Getting Started: Scanning without any reference points. Just select the right template in the software, define the background plane and start your 3D scan. Have you got any questions? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: The new Satellite mode

In this Getting Started we demonstrate how to accurately scan large parts with photogrammetry. The new integrated satellite mode ensures precise pre-referencing. No other features, like coded markers, are necessary. Watch the video to see the T-SCAN hawk 2 unleash its full potential.

Do you want to find out more about the portable 3D laser scanner T-SCAN hawk 2? Visit HandsOnMetrology.com/sessions

T-SCAN hawk 2: Scanning fine details

Whether you are scanning large parts with local details or a completely detailed part, T-SCAN hawk 2 is the right solution. Let Aysel explain you, how to operate the scanner and get useful tips and tricks for both cases. Have you got any questions? Contact us via support@HandsOnMetrology.com

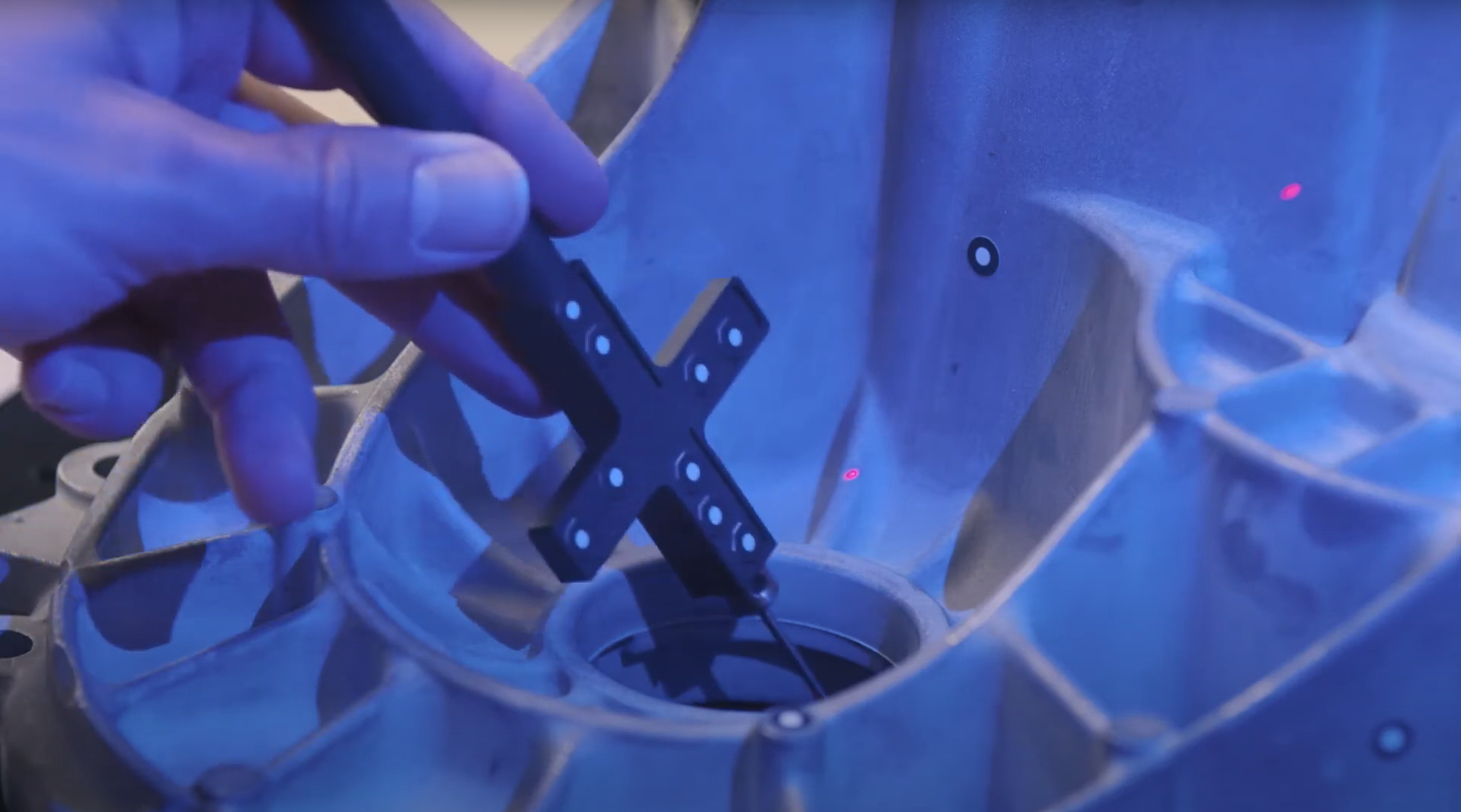

T-SCAN hawk 2: Scanning deep pockets

Your challenge is to scan deep pockets of a part? The single laser line mode of the T-SCAN hawk 2 allows you to scan even deeper into wholes. Watch the Getting Started to learn more about the detailed scan of hard to reach areas. Have you got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: All features of the remote control buttons

Let Aysel show you the different possibilities of the control buttons on the back of the T-SCAN hawk 2. It makes starting the remote workflow, zooming in and out, opening the menu and more as easy as a push of the button. Have you got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Accessories

You want to scan your parts without sticking reference points on it? We have the right accessory for you: the magnetic reference pillars. Placing them around the part ensures easy, intuitive and accurate data collection. Have you got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

T-SCAN hawk 2: Get some useful tips & tricks

Need more tricks on the new T-SCAN hawk 2? Aysel is going to reveal useful tips that make your scanning process even more successful. Get more information on topics, like exposure modes, scanner orientation, defining background planes and customizing workflows. Have you got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to scan large parts using ZEISS T-SCAN hawk 2

Looking for an easy and intuitive way to 3d scan large parts up to multiple meter? Then the 3D laser scanner ZEISS T-SCAN hawk 2 with the new satellite mode is the right solution for you. Let Matthias show you how it’s done.

Do you have any questions about ZEISS T-SCAN hawk 2? Contact us via support@HandsOnMetrology.com

How to 3D scanning for fast and efficient incoming inspection in MRO

Keeping equipment in good condition is necessary for an efficient production process. 3D scanning helps to capture all dimensions of parts for a fast inspection. Roel shows you how reparation or modification of equipment can be done using hand-held solutions. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to perform fast inspection in electric motorcycle assembly

Components with different tolerances, make building safe motorcycles a challenge. Let Alex show you how easy it can be to inspect single motorcycle components and the digital assembly with ZEISS T-SCAN hawk 2 and the inspection software of the ZEISS Quality Suite. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to set up a digital warehouse with 3D scanning

3D scanning helps to create your digital warehouse in MRO. With the digital copy you have important information at hand in the event of a sudden defect. Reduce costs due to extended downtime or storage, and easily access your digital inventory where and when you need it. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to reproduce unavailable spare parts in MRO

Currently facing the challenge of reproducing unavailable spare parts? 3D scanning might be the solution you need to minimize risky downtime. By capturing the dimensions of the equipment, a reproduction is possible in no time. Watch the How to to learn more about it. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to 3D scanning for wear control in MRO

Wear and tear of production equipment causes malfunctioning, delays, downtime. In this How to, Roel shows you how 3D scanning is used to implement predictive maintenance – and therefore keep production running efficiently.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to weld check on electric motorcycle frames

The basic structure of a motorcycle is the welded frame. Weld inspection is therefore necessary not only to maintain quality of parts, but also for customer safety. With the ZEISS T-SCAN hawk 2 and the weld inspection package of the ZEISS Quality Suite, you can easily scan, classify and inspect welds. Let Juan show you how it’s done.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How does satellite mode work and why do you need it

Scanning larger parts can be challenging. We simplified the the process with the new satellite mode of the handheld laser scanner ZEISS T-SCAN hawk 2. It does without coded markers thus preparations are easy and fast. Learn more about the advanced way of photogrammetry here. Got any questions? Contact us via support@HandsOnMetrology.com.

How to use a 3D scanner for dent detection

Looking for a way to speed up and refine your aircraft MRO? Let Roel show you how the ZEISS T-SCAN hawk 2 and the Inspect Software aid in various inspection tasks, like GD&T, CAD comparisons or defect maps. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to measure in production

Small and portable: the ZEISS T-SCAN hawk 2 is made for the use in production. See here how it supports your complete process chain from data collection for reverse engineering, different inspection tasks to the digital assembly of produced parts.

Do you want to find out more about the portable 3D laser scanner T-SCAN hawk 2? Visit HandsOnMetrology.com/sessions

How to scan large objects using a portable 3D scanner

Learn how to measure big parts, like sand molds. Roel is using the new Satellite Mode of the ZEISS T-SCAN hawk 2 – replacing the built-in photogrammtry of the previous scanner generation. Together with scale bars, reference points and the big field of view of the handheld sensor, it is a powerful combination which ensures highly accurate data.

How to use a 3D scanner in confined spaces

In this How to Roel is scanning complex and hard to reach areas of a van interior. Whether for inspection or design purposes – the ZEISS T-SCAN hawk 2 is the perfect fit for extracting accurate and complete dimensions in confined spaces. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

ATOS Q

ATOS Q: Start a project in ZEISS INSPECT

Let Dokus show you how to make your first scan with ZEISS INSPECT. He takes you from the start screen to the checkered flag: a very detailed mesh. See different workspaces and scanning templates. Learn how to scan and watch what happens when you rotate the table.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

Chapters

00:42 Start software

01:03 Workspaces

01:33 Digitizing workspace

01:58 Main toolbar

02:22 First scan and cut out background

02:50 Reference points

03:18 Polygonize and recalculate

ATOS Q: Unboxing your new 3D scanner

Meet Dokus and the ATOS Q with its two cases. The first case contains the ATOS Q sensor and everything you might need on location, from rotation table to measuring volumes or the calibration plate. The second, smaller case contains the laptop and the mobile controller.

Chapters

00:27 The case

00:50 First compartment level

01:05 Second compartment level

01:26 Bottom compartment level

01:34 Mobile controller

01:52 The laptop

ATOS Q: How to set up the system

Watch Dokus set up the ATOS Q scanner and connect the sensor to the laptop. From opening up the mobile controller and mounting the sensor on the tripod to plugging in the licence key and connecting the automatic rotation table, he guides you step by step

ATOS Q: Change to a small measuring volume

If you need a high resolution for a small, detailed object, switching measuring volumes is easy with this 3D scanner. Dokus shows you step by step how to prepare and change the lenses, define the measuring volume in GOM Inspect Suite and calibrate the sensor.

ATOS Q: How to measure big parts

Use the 3D scanner ATOS Q to scan a large part with the measuring volume MV500. Even if the object is bigger than the measuring volume, you can capture it easily using reference points and stitching scans to get a high quality result including small details.

Chapter:

00:42 Start new project and perform first scan

01:24 Stitching scans with reference points

02:01 Finish scan

ATOS Q: How to measure top and bottom of a part

In this video, Dokus measures a part from the top and the bottom side to create a digital twin. A fast and easy workflow with the 3D scanner ATOS Q, assisted by the automatic rotation table and GOM Inspect. After measuring, simply combine and polygonize the data.

Chapters

00:38 Start new project

00:54 Use rotation table

01:38 Flip over the part

01:55 New measurement series

02:42 Combine top and bottom

03:23 Polygonize and recalculate

ATOS Q: Measure with the automatic rotation table

Learn how to use the automatic rotation table to speed up the 3D scanning workflow with ATOS Q. GOM Inspect allows you to choose the number of automatic rotations. A rule of thumb: With 8 rotations you capture almost every aspect of the part.

Chapters

00:45 Rotate rotation table

01:14 Select scanning template and perform first scan

01:41 Use rotation table

02:20 Polygonize and recalculate

ATOS Q: Add single points with a touch probe

Learn how to use a touch probe to capture 3D data. Dokus shows you how to scan in difficult-to-reach areas and explains guided touch probe measurements in GOM Inspect Suite.

Chapters

00:27 The touch probe

00:49 Live workspace

01:16 Select touch probe

01:44 Finish measurement

02:00 Guided touch probe measurements

02:42 Start guided touch probe measurements

ATOS Q: Tips & tricks to scan even faster

Dokus gives valuable tips on using the 3D scanner ATOS Q. Learn how to measure the automatic exposure time and move the focus point, how to change into fast scan mode – if you don’t need details – or how to manually cut out points.

Chapters

00:42 Automatic exposure time

00:59 Move the focus point

01:36 Fast scanning

02:22 Cut out points

02:52 Selection tools

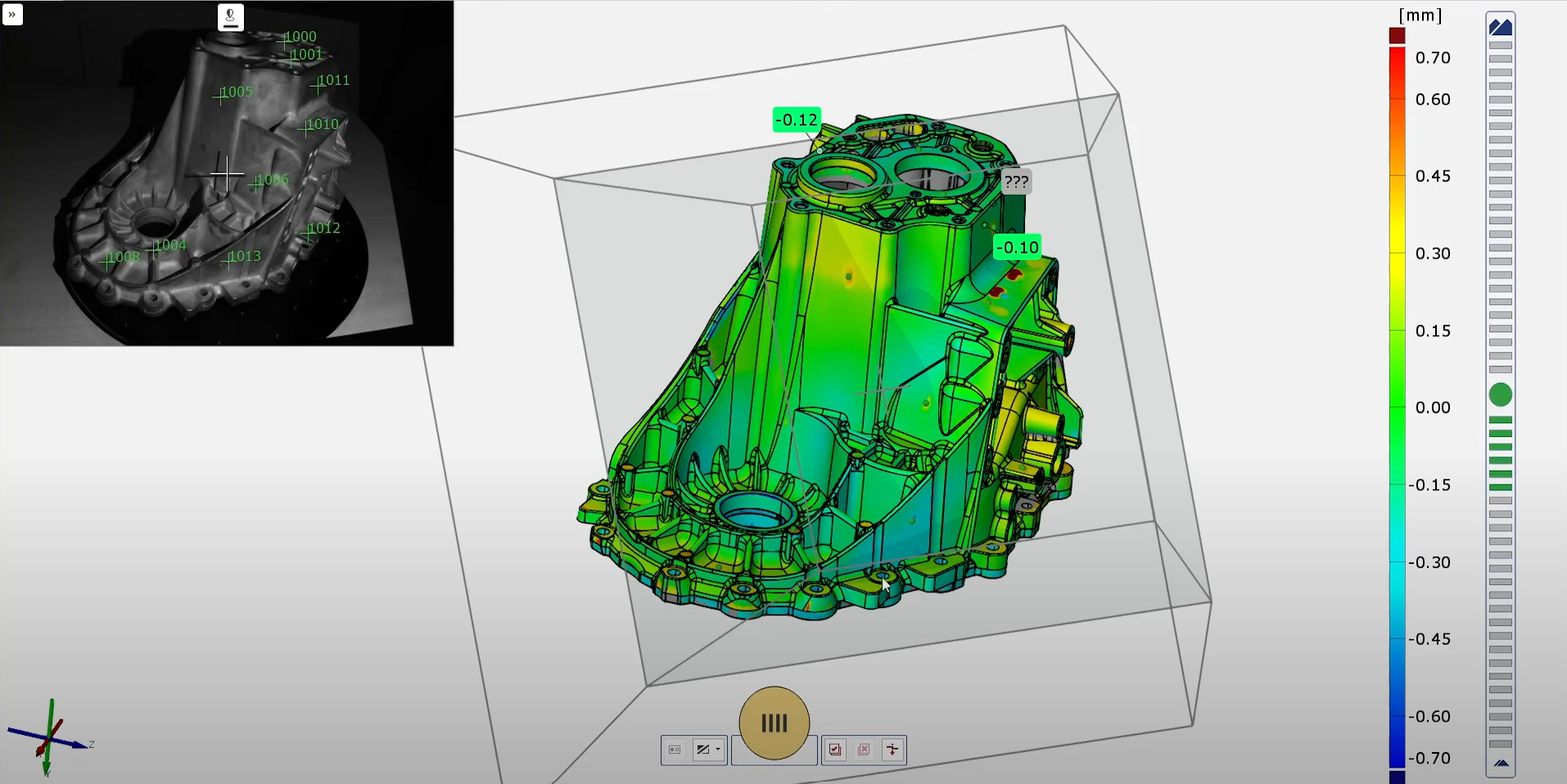

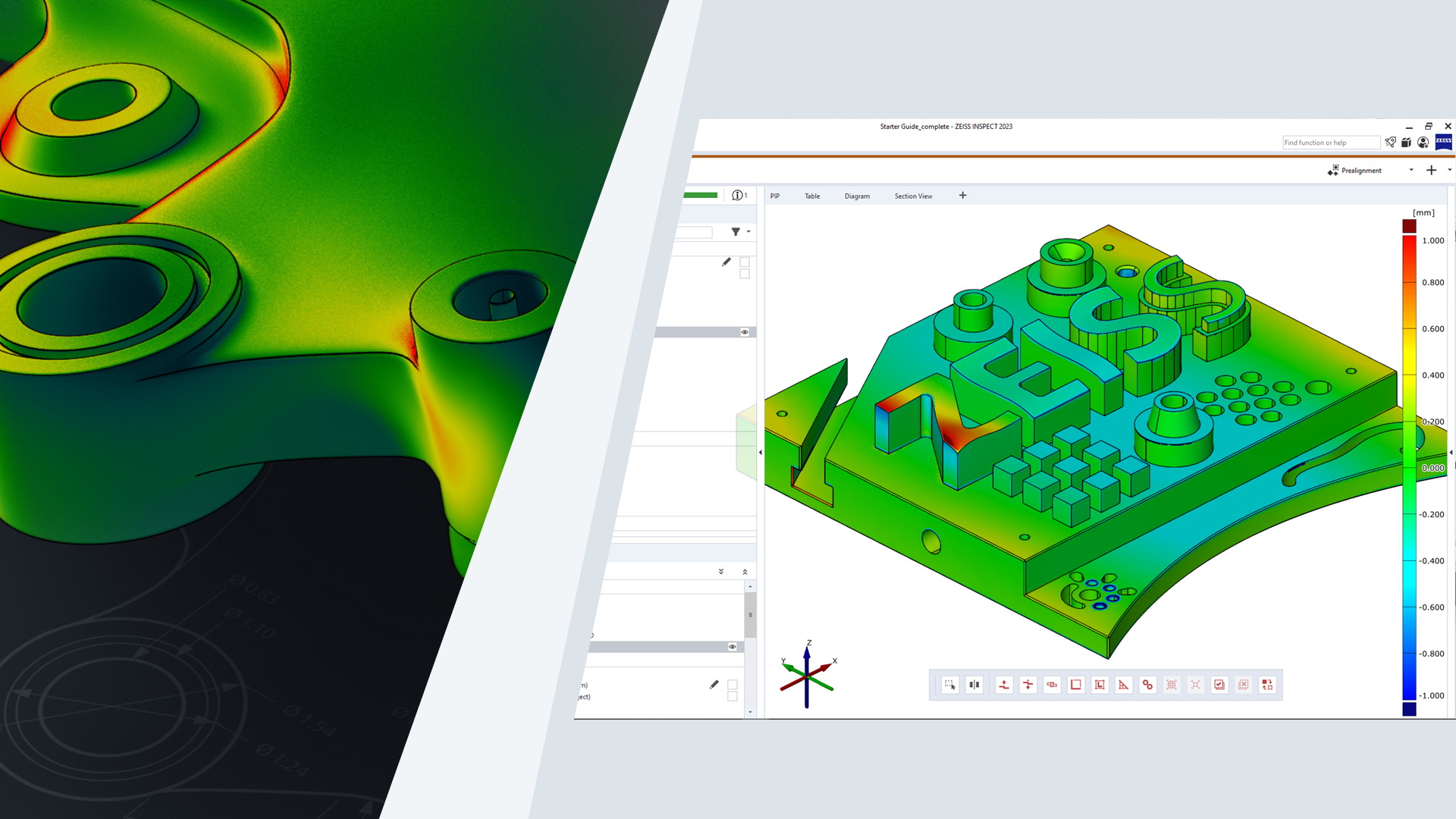

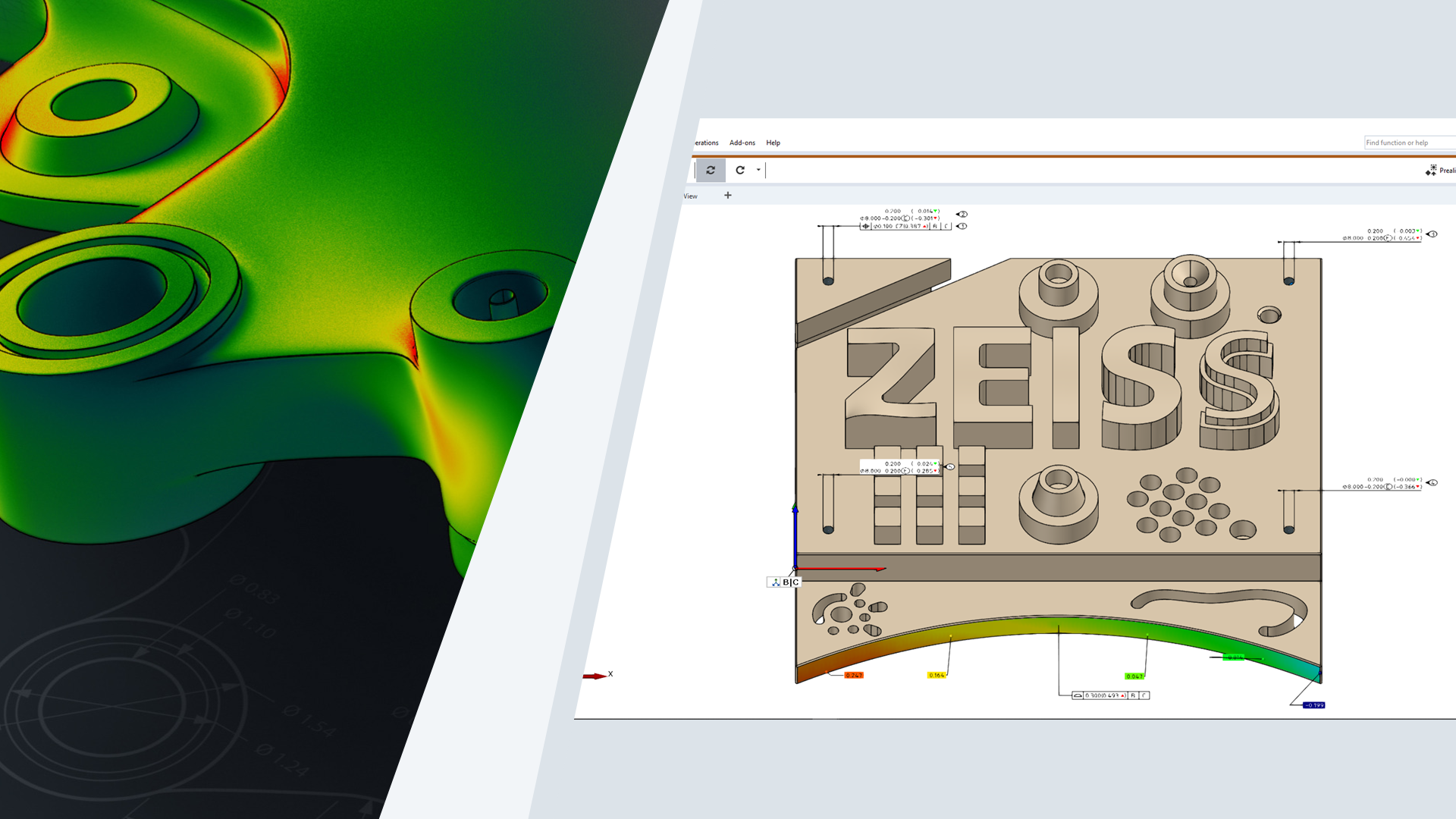

ATOS Q: Fast inspection with ZEISS INSPECT

Learn how to perform a fast inspection in ZEISS INSPECT by preparing a project in the inspection workspace, including the prealignment of a CAD file and a surface comparison. After the first scan, you can immediately look at the results.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

Chapters

00:29 Prepare the project

00:53 Inspection workspace

01:32 Prealignment

01:44 Surface comparison

02:04 Digitizing workspace

02:30 Automated recalculation through parametrics

How to save time with ZEISS INSPECT

Let Matt show how quality control becomes more efficient using the full version of ZEISS INSPECT. Whether inspecting one or multiple parts, templates transfer pre-made inspection steps in one click. Trend project function furthermore helps when all parts need to be checked at once – making evaluation fast, easy and intuitive.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to 3D scan multiple parts with ATOS Q

Learn how to scan multiple identical parts simultaneously using the ATOS Q and a rotation table. Simply choose the workflow assistant for scanning multiple parts and follow the software as it guides you through the scanning process. Since the rotation table is marked with reference points, you can start scanning straight away. Partitioning the parts and aligning top and bottom scans is done with just a few clicks.

Do you have any question on our 3D scanners? Contact us via support@HandsOnMetrology.com

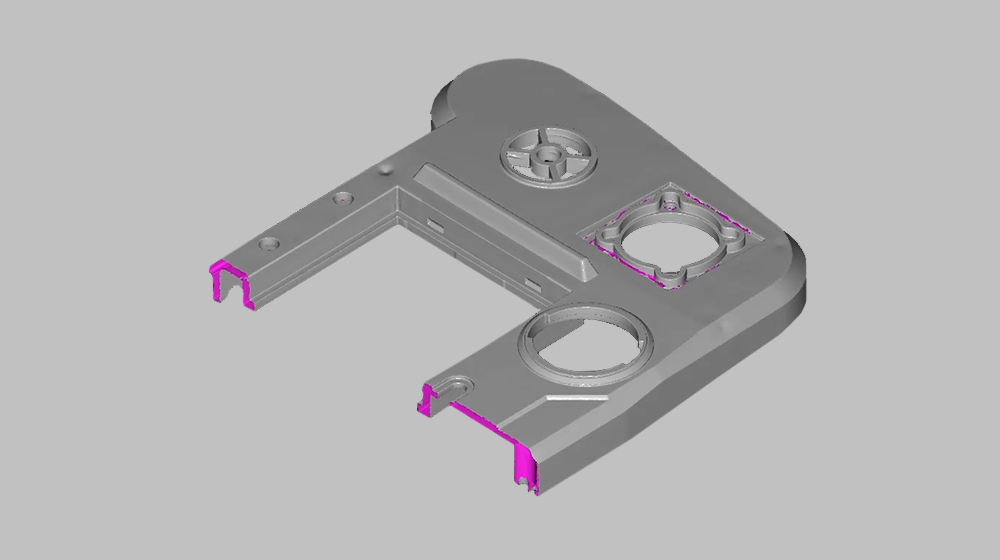

How to eliminate plastic warpage in Quality Control

Annoyed about plastic warpage and how it makes quality control of unassembled parts difficult? In this video, Toon shows you how to solve this problem: with the De-warp function that can be found in the full version of ZEISS INSPECT . It puts scanned plastic parts into a virtually assembled state, allowing you to check their dimensions as if they were assembled.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to perform a digital assembly in GOM Inspect

How to 3D scan objects without reference points

How to 3D scan faster with an automated rotation table

How to get even more out of your ATOS Q

How to use 3D scanning to build up rally cars

METROTOM 1

METROTOM 1: The Setup

The 3D scanner ZEISS METROTOM 1 is powered by CT technology and allows you to inspect internal structures that can’t be detected with tactile or optical measuring systems. Sounds interesting? In this Getting Started video Aysel and John will teach you how to set up the hardware. Find out how to power up. Discover the scanner’s control hardware with all its switches, buttons and functions. Then learn how to connect the solution to the software ZEISS INSPECT and warm up the X-ray tube.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

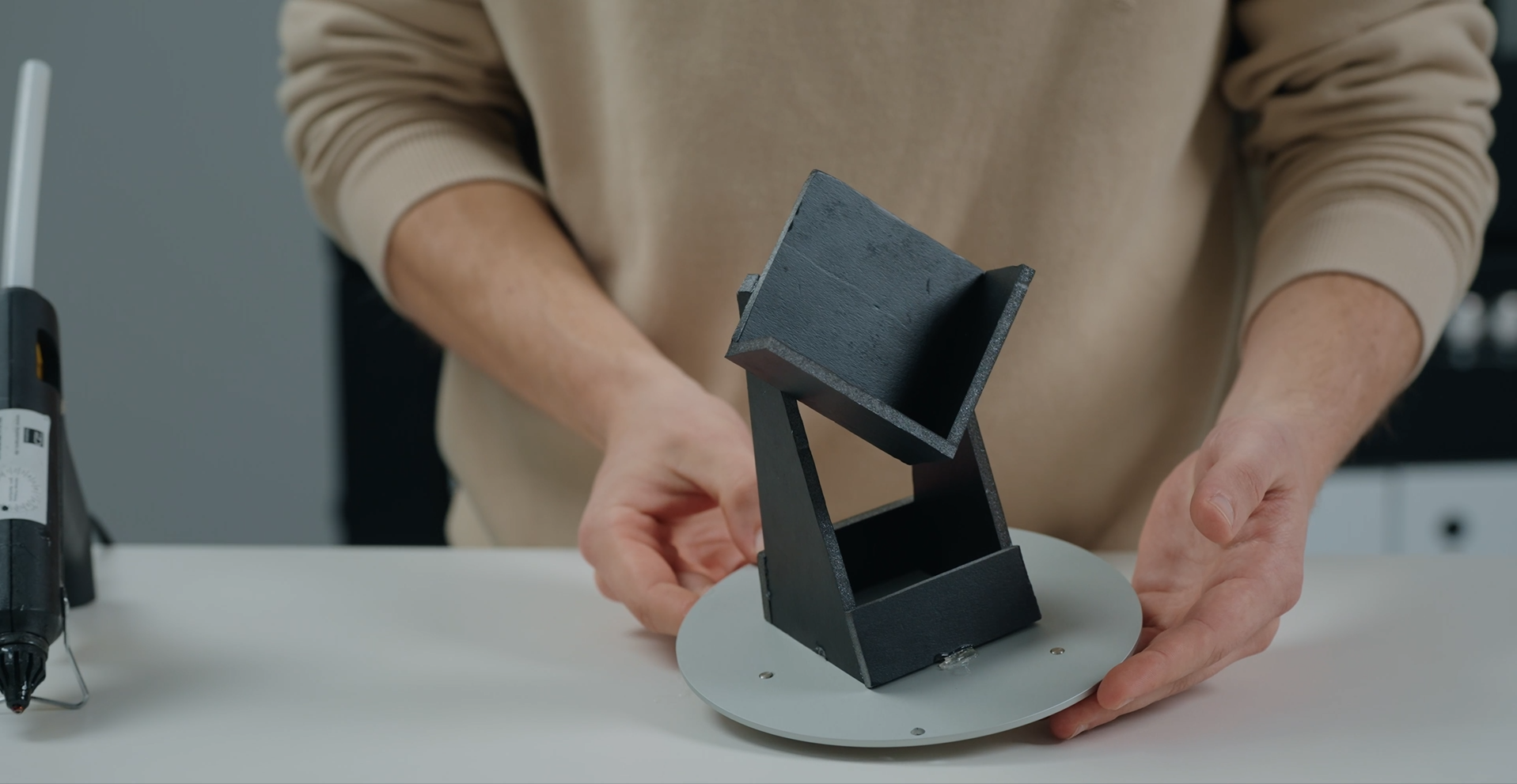

METROTOM 1: Easy part fixture

So you got yourself the 3D scanner ZEISS METROTOM 1 – powered by CT technology – and want to learn how to fix a part so it won’t move during the scan? In this Getting Started video Aysel and John will show you a few quick and cost-efficient tricks for creating the perfect part fixture. Watch the two 3D experts as they get crafty with insulation foam and hot glue before placing their part on the fixture plate and locking it into the rotation table inside the system.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Introduction to ZEISS INSPECT

ZEISS METROTOM 1 – powered by CT technology – is yet another 3D scanning solution that fully reaches its outstanding potential once connected to the software ZEISS INSPECT. Follow Aysel and John, as they take you into ZEISS INSPECT via the ZEISS Quality Suite, and get a quick tour around the four different workspaces, dedicated to scanning, inspecting, reporting and mesh editing.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Quick & easy calibration

In this video, Aysel and John will show you how to calibrate the 3D scanner ZEISS METROTOM 1. The solution comes with a calibration object and fixture device so you can recalibrate at any time. Good news: The software ZEISS INSPECT guides you through the process. After that, your METROTOM 1 is ready for 100 % accurate 3D scanning.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Scanning single parts

You want start your first 3D scan with ZEISS METROTOM 1 so you can inspect the internal structures of a part via CT technology? Then watch Aysel and John’s Getting Started video first: Their step-by-step tutorial takes you through the basic scanning strategy of scanning a single, transparent plastic part. You’ll learn about all the adjustments to be made on the METROTOM 1 before the scan – including the adjustment of the filter wheel and the x-ray tube parameters voltage, power and exposure time. Just follow them along – it’s easy.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Scanning multiple parts

The 3D scanner ZEISS METROTOM 1 – powered by CT technology – is perfect for scanning multiple parts at once, as it seriously reduces scan times. Interested? Then watch Aysel and John’s tutorial. Learn how to prepare the parts for 3D scanning, discover how to set up the software – and experience its simple, built-in separation tool: for separating out the batch volume into smaller volumes for each individual part.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Easy volume visualization

When combined with the software ZEISS INSPECT, the 3D scanner ZEISS METROTOM 1 offers incredible advantages for the inspection of internal defects – and John and Aysel know all the visualization tricks. Follow their tutorial to learn about slicing through a part in order to look inside. Scroll through parts with the clever picture-in-picture view. Choose the multi-view function for a view of all three directions. And get several insights at a single glance by making the mesh and CAD visible, too.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

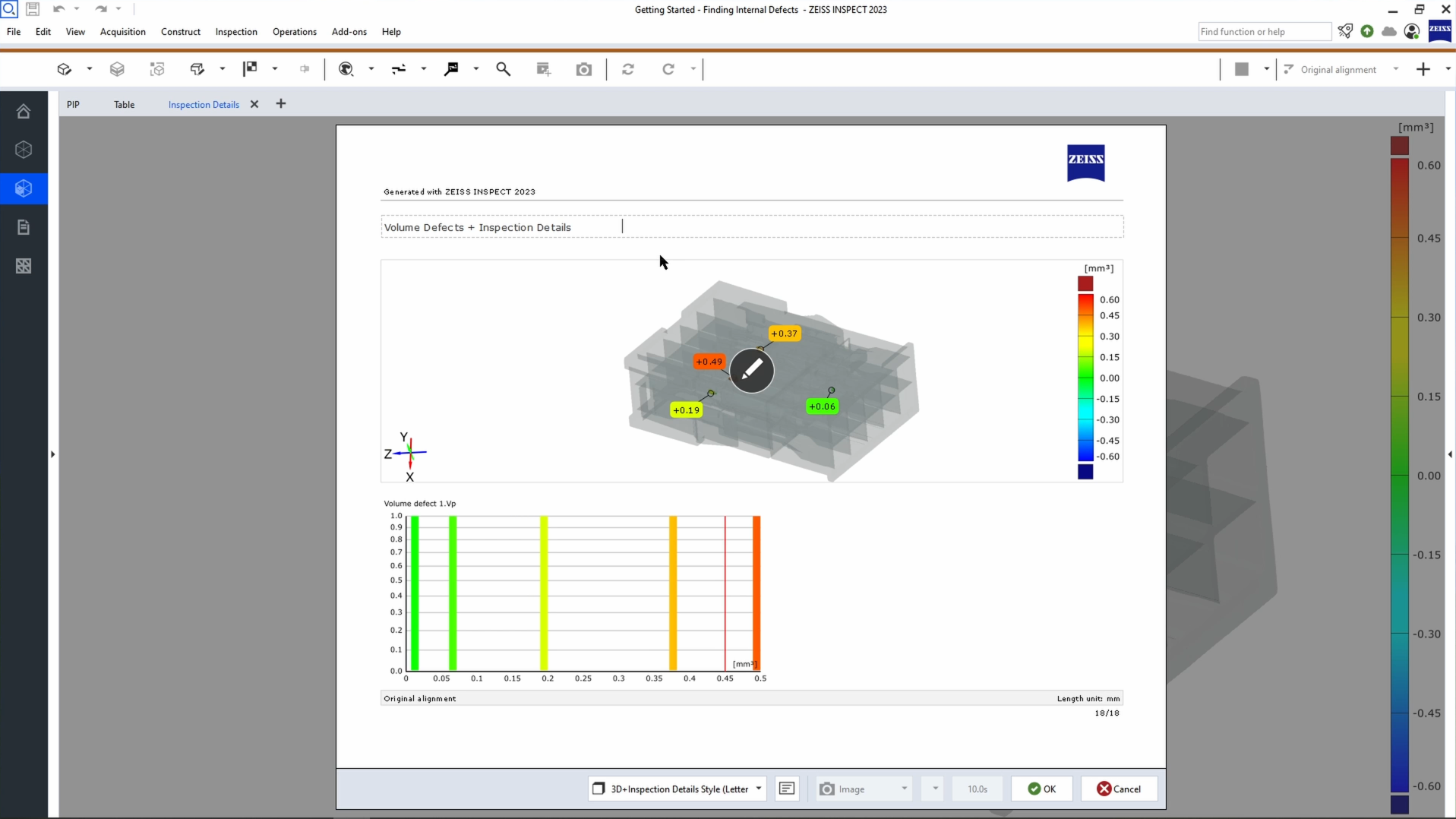

METROTOM 1: Easy internal defect inspection

You’re looking for a solution to help you locate and classify internal part defects? Then ZEISS METROTOM 1 – powered by CT technology – is the perfect solution and this video teaches you how it’s done. Learn how to do automated, high-quantity internal inspections on the digital twin of any part. Take a look at all aspects of a defect – from porosity percentage or defect volume to defect length or defect distance to the surface of the part.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Automated parameter selection

What makes the use of your 3D scanner ZEISS METROTOM 1 even more convenient? Automated parameter selection: a standard function in ZEISS INSPECT. Sounds interesting? In this video you’ll learn how to let the solution calculate suitable parameter settings for you – based on part shape, thickness, density and desired scan resolution. Time for you to sit back and wait for the magic to happen.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

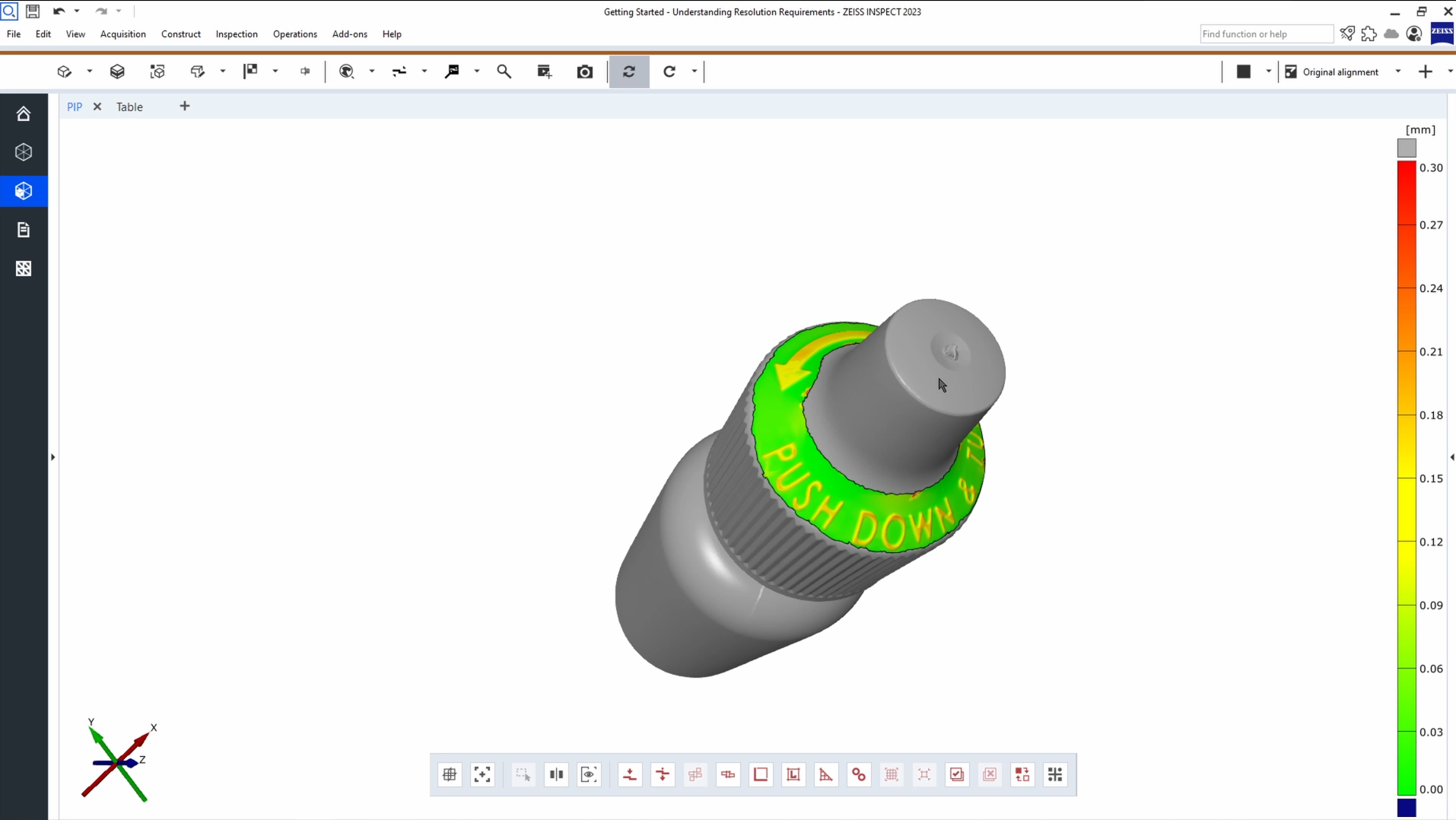

METROTOM 1: Introduction to scan resolution

The 3D scanner ZEISS METROTOM 1 – powered by CT technology – is a versatile system with a useful set of pre-defined scan resolutions to cover a wide range of objects and measuring tasks. In this Getting Started video you’ll get an introduction to scan resolution requirements. You’ll learn how to calculate a suitable resolution with a simple rule of thumb. You’ll discover the advantages of 3D scanning in a lower or higher resolution. And you’ll discover the system’s most commonly used resolution settings.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

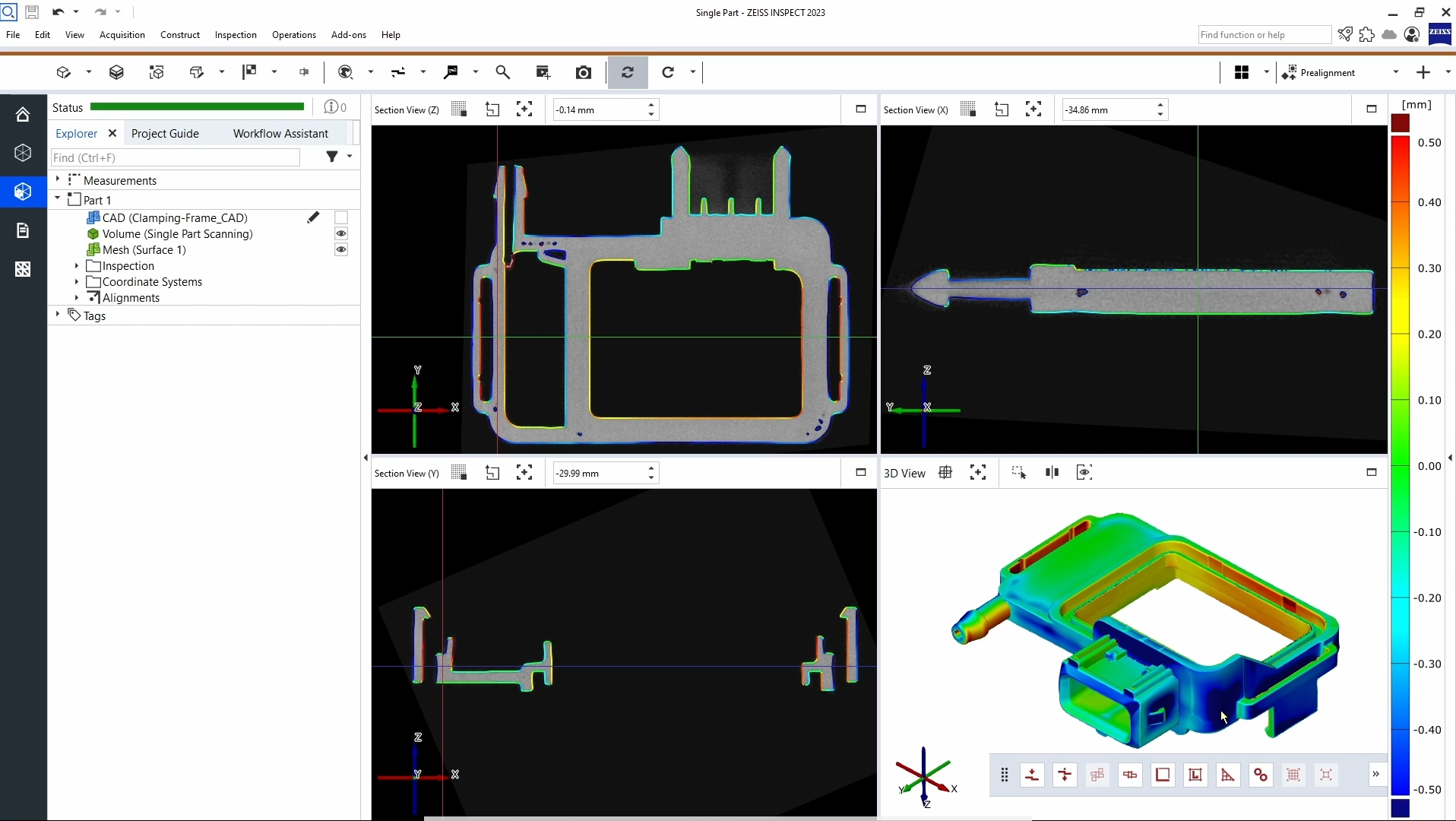

METROTOM 1: Part inspection with CAD data

In this Getting Started Aysel and John will show you how to inspect a 3D scan of your METROTOM 1 using not only scan data but CAD data, too. Find out about the benefits of 3D inspection with CAD data. Discover how to join and align a scan mesh with a CAD file. Learn about the software’s surface comparison, distance inspection and GD&T analysis function. The cherry on top: all inspections are documented in the report workspace – making reporting extra easy.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: How to inspect the inside of electronic connector housings

Did you know that the 3D scanner METROTOM 1 is ideal for the overall inspection of electronic connectors housings? Let Alex show you how a simple 3D scan – powered by CT technology – can provide you with valuable data to determine the external and internal part quality.

Do you have any question on our 3D scanners? Contact us via support@HandsOnMetrology.com

Consiga el software 3D, inicie el

proyecto.

Software

ZEISS REVERSE ENGINEERING

ZEISS REVERSE ENGINEERING: Software user interface

In this video, Josh provides a quick overview of the ZEISS REVERSE ENGINEERING software user interface and shows you how to set up and start using the software. He covers the basics, including the software settings, the workspaces and some additional functionalities. Watch it and get started!

All functions shown are available in the current software version.

Got any questions on the ZEISS software? Contact us via support@HandsOnMetrology.com

ZEISS REVERSE ENGINEERING: Most common functions

Discover the most common functions of ZEISS REVERSE ENGINEERING. In first place: the «extract surfaces from parts» function, which leads directly to the «extract solid body» function – two powerful tools, especially for geometry-based parts. Second place: the creation of symmetric parts. Third place: the creation of freeform surfaces. And last but not least: the analysis function of your parts. Let Josh show you what’s what.

All functions shown are available in the current software version.

Got any questions on the ZEISS software? Contact us via support@HandsOnMetrology.com

ZEISS REVERSE ENGINEERING: Importing data

Take it from Josh: Importing data into ZEISS REVERSE ENGINEERING is just as easy as importing it into ZEISS INSPECT. If ou’re already using ZEISS INSPECT, simply export into ZEISS REVERSE ENGINEERING. Alternatively, you can drag and drop files from your file explorer or use the import option as the top of ZEISS REVERSE ENGINEERING. Want to know which file types are supported? Simply take a look at the user guide.

All functions shown are available in the current software version.

Got any questions on the ZEISS software? Contact us via support@HandsOnMetrology.com

ZEISS REVERSE ENGINEERING: Edit and align meshes

Let Josh show you how to align and edit your mesh in ZEISS REVERSE ENGINEERING. Step 1: Align your mesh with the «best fit via three planes» function to review your part in an intuitive manner. Step 2: Edit your mesh by closing small holes with the «fill holes in mesh automatically» function. Now you have a fully closed and aligned mesh without any unwanted data – and you’re ready to start the reverse engineering process.

All functions shown are available in the current software version.

Got any questions on the ZEISS software? Contact us via support@HandsOnMetrology.com

ZEISS REVERSE ENGINEERING: Tips and tricks

In this video, Josh lets you in on some handy tips and tricks to help you get started even faster with ZEISS REVERSE ENGINEERING. Learn how to bookmark your favorite functions. Discover how the transparency tool can help you get a better look at specific elements. Learn about how the snapshot tool makes it easy for you to create images for reports. Start using the «fit to screen» icon to get a better view of your part. And minimize clicks by looking at the shortcut list in the user guide.

All functions shown are available in the current software version.

Got any questions on the ZEISS software? Contact us via support@HandsOnMetrology.com

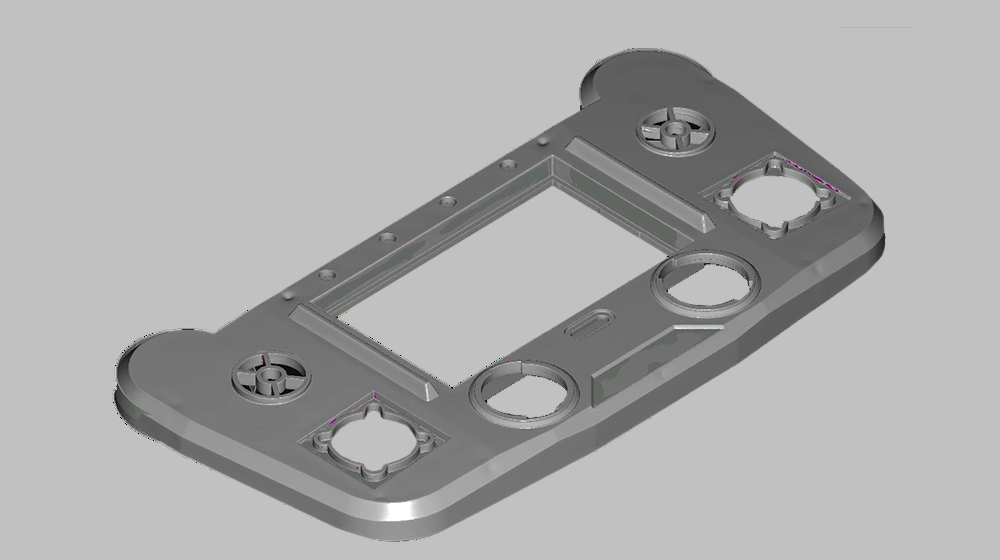

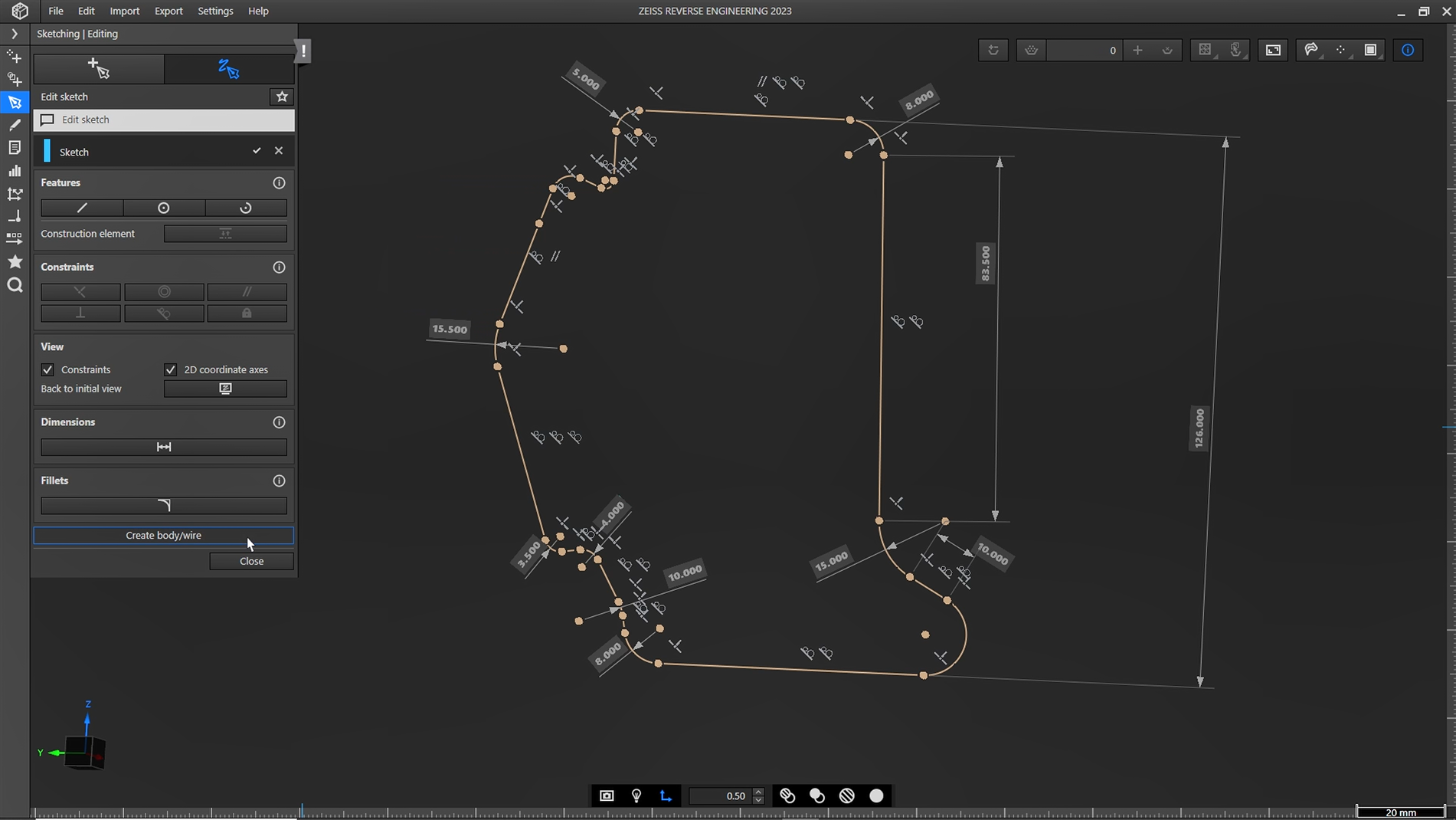

New Sketching function in ZEISS REVERSE ENGINEERING

Looking for an easy way to get more control over your reverse engineered models? With the new sketching function in ZEISS REVERSE ENGINEERING, creating CAD models is easier than ever. Your benefit: fully dimensioned and constrained CAD from scan data.

Do you have any questions about ZEISS REVERSE ENGINEERING? Contact us via support@HandsOnMetrology.com

ZEISS REVERSE ENGINEERING: How to create a CAD file out of manually modelled parts

Looking for an easy way to create a CAD out of your individually modelled part? Let Matt show you how! With the help of the ATOS Q and the ZEISS REVERSE ENGINEERING software the part gets digitized and undergoes step by step virtual modeling. Helpful features support the process to enable fast and intuitive work.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

ZEISS REVERSE ENGINEERING: How to transform your 3D scans into CAD models

Meet Josh and let him show you how to transform your 3D scans into CAD models using the software ZEISS REVERSE ENGINEERING. Wether you want to reverse engineer a geometrical part, a freeform shaped part or an organic shaped part – Josh gives you a quick introduction to each task, from scanning to obtaining a CAD model.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

ZEISS INSPECT

ZEISS INSPECT: Optical 3D User Interface

Find out how to perform accurate 3D data evaluation in ZEISS INSPECT. Whether you are facing simple or more complex inspection tasks, the software has it all: mesh editing functions, CAD import, GD&T inspections, trend analysis and digital assembly.

Do you have any questions about ZEISS INSPECT?

Contact us via email: support@HandsOnMetrology.com

ZEISS INSPECT: Data import

Starting your 3D inspection is easy with ZEISS INSPECT. Learn which formats are supported in our software and how easy it is for you to import your 3D data.

Do you have any questions about ZEISS INSPECT?

Contact us via email: support@HandsOnMetrology.com

ZEISS INSPECT: Performing single inspection

Learn how to compare your 3D data to the CAD in ZEISS INSPECT. The software solution offers you a wide range of inspection possibilities, like the color plot, deviation labels for discrete deviation labels or the clipping functionalities for small or hard to reach areas.

Do you have any questions about ZEISS INSPECT?

Contact us via email: support@HandsOnMetrology.com

ZEISS INSPECT: Performing GD&T inspections

Learn how to compare your 3D data to the CAD in ZEISS INSPECT. The software solution offers you a wide range of inspection possibilities, like the color plot, deviation labels for discrete deviation labels or the clipping functionalities for small or hard to reach areas.

Do you have any questions about ZEISS INSPECT?

Contact us via email: support@HandsOnMetrology.com

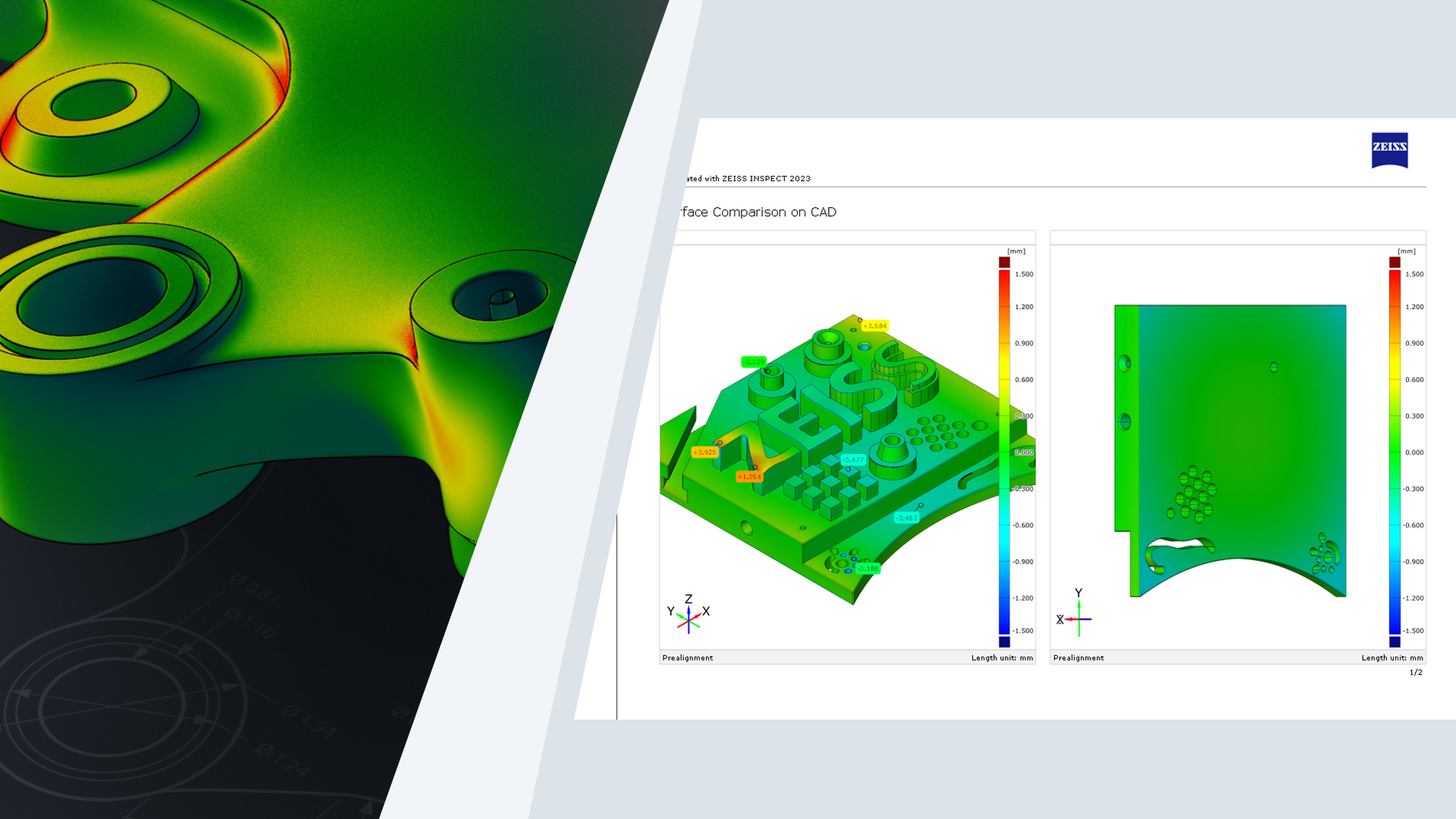

ZEISS INSPECT: Reporting

Need tips on how to create, edit and present your 3D inspection reports? The ZEISS INSPECT report workspace got you covered. Learn here how to use the workspace to receive comprehensive and customizable reports pages.

Do you have any questions about ZEISS INSPECT?

Contact us via email: support@HandsOnMetrology.com

How to perform CAD surfacing in ZEISS INSPECT

No CAD available for projects like 3D printing? The new surfacing function in ZEISS INSPECT got you covered. With a simple mouse click you receive a customizable CAD based on our 3D scan data. Let Luca show you how to simplify the creation of CAD with the latest release ouf our software solution.

Do you have any questions about ZEISS INSPECT? Contact us via support@HandsOnMetrology.com

How to deliver first class report presentations

Let Norman show you how to deliver impressive presentations with ZEISS INSPECT. Simply export your measurements to a PDF? It’s an option, but a static one. You can do better! Simply open ZEISS INSPECT in the meeting room, hit the F5 key for the presentation mode – and get the option to zoom in or rotate the part and adjust the display. You can even show your mesaurement results on the object – with the help of a tablet and AR. Now, that’s impressive.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

¿Desea más información sobre nuestras soluciones 3D?

Póngase en contacto con su socio local de #HandsOnMetrology.