Fast start: Simple parts with GOM Scan 1

When your part isn’t too complex, GOM Scan 1 is a compact, dependable choice for everyday tasks. Setup is straightforward:

1.

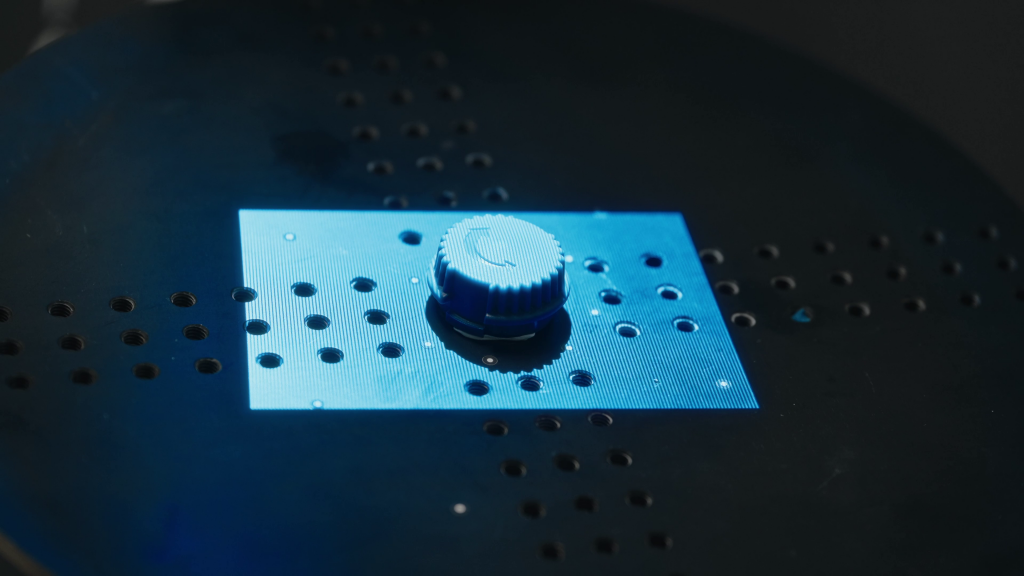

Mount the scanner on a standard tripod or a desk stand with a small turntable

2.

Place the part on a turntable between the reference points

3.

Use the workflow assistant to scan the part

The workflow assistant in ZEISS INSPECT guides you step by step through the process. This ensures consistent results, even for less experienced operators.

Detailed parts: Capturing fine features with ATOS Q

For intricate geometries and small features, ATOS Q delivers the required details and accuracy. This 3D scanner is more versatile because of the exchangeable lenses that allow for a wide range of metrology tasks. For small parts, a 50 mm measuring volume with up to 12 megapixels resolution is the right solution.

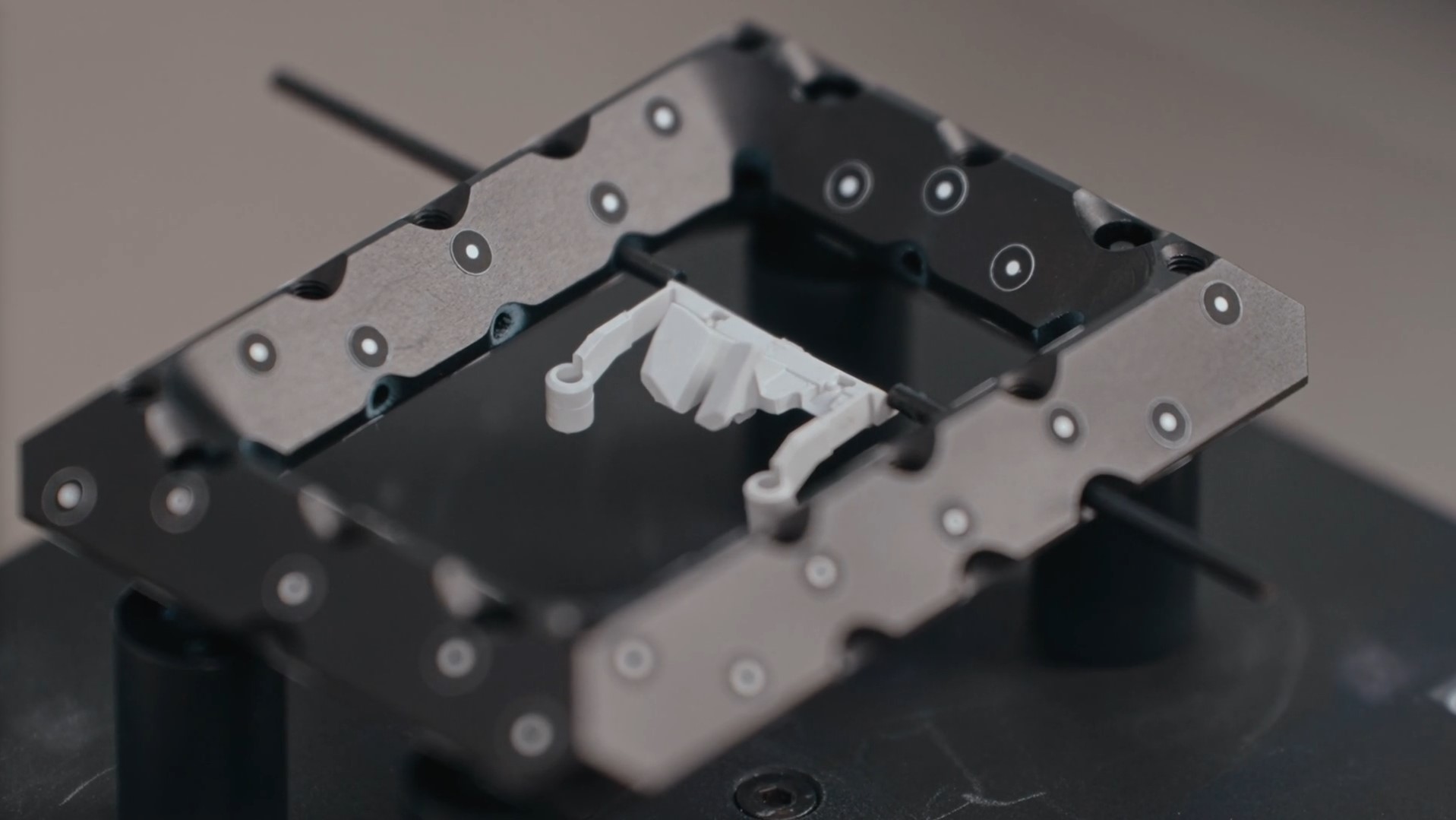

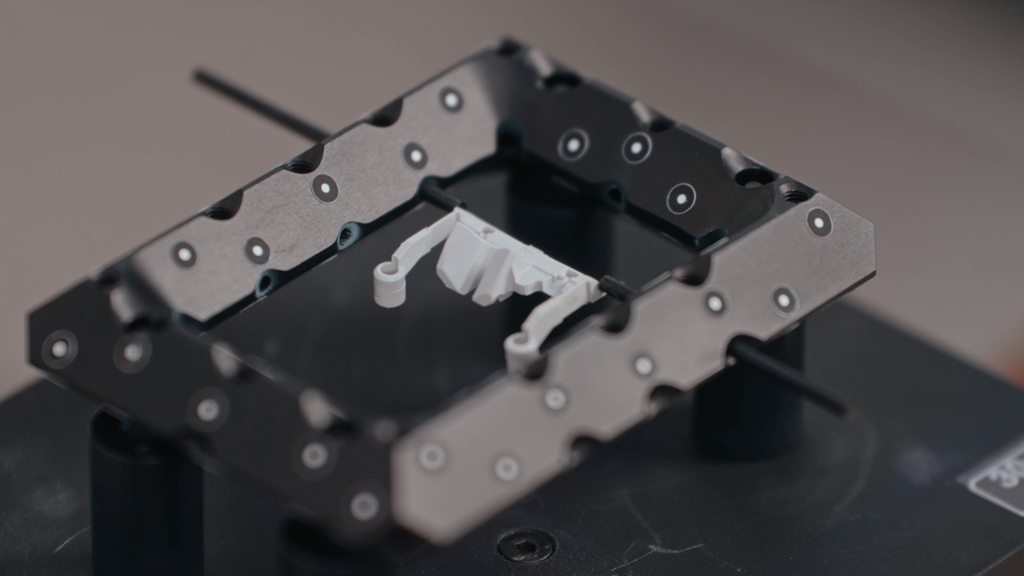

Pairing ATOS Q with a motorization kit takes your scanning a step further. It makes it easy to capture the part across multiple angles and rotations. For very small parts, placing reference points on the part may not be possible. Instead, place the points on the turntable or use a reference frame. Scanning the part takes just a few minutes, and you’ll have a complete, high-detail dataset.

A practical workflow might look like this:

1.

Place the part on the turntable

2.

To scan complex features, define the number of angles and turns. For example, 2 angles and 8 turns

3.

Scan the top, flip the part, and scan the bottom

Additional software features: Motion Replay, project templates, and Kiosk Mode

Motion Replay enables fast, repeatable scans for recurring parts. The software records all measurement positions and repeats the same scan on subsequent parts at the touch of a button.

Scanning small parts becomes even easier with project templates. These templates include the scanning, inspection and reports. The inspection is fast and reliable and there’s no need for an expert, as it is now done automatically.

Kiosk Mode keeps things simple. Operators simply enter their name and the part’s serial number, and press start. After scanning, the software automatically performs the full inspection. You can then review the generated report and approve or reject the part.

Watch the full video

With the right tools and workflow, small parts can be scanned quickly, precisely, and repeatably. GOM Scan 1 offers an easy entry for simple parts. For detailed features, ATOS Q in combination with a motorization kit is the right choice. Motion Replay, project templates, and Kiosk Mode offer additional capabilities to streamline, standardize, and simplify your scanning and inspection process. Watch our How-to video to learn more about scanning small parts.

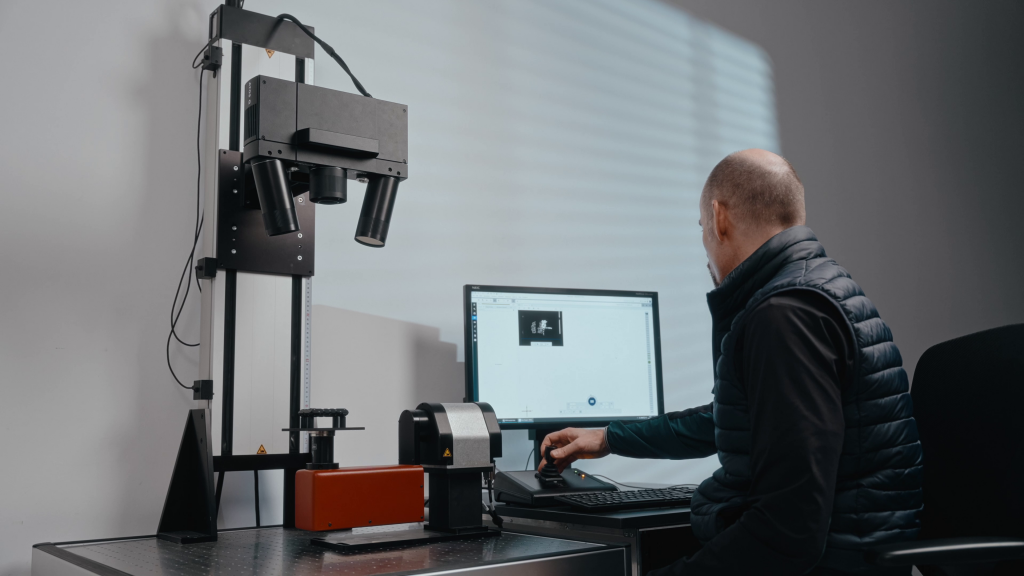

How to scan small parts using compact 3D scanners

3D scanning of small parts and fine details is often a challenge that can take a lot of time. In this How-to, Matthias shows you how you can take the 3D scanning process to a new level with the help of ATOS Q, GOM Scan 1 and the Motorization Kit.

Do you have any question on our 3D scanners? Contact us via support@HandsOnMetrology.com

GOM Scan 1

ATOS Q

How Immensa transforms the physical into digital

Dive into the fascinating world of Immensa, a company that’s making waves in the supply chain and manufacturing sectors. Immensa is well-known as a supply chain technology company or as an on-demand manufacturer. But what truly sets them apart is their unique ability to transform physical objects into digital assets. Let’s explore how they’re bridging the gap between the physical and digital!

Inspect the insides of medical plastic parts

Medical parts are often transparent and translucent which can be tricky for optical measurements. At the same time, medical components require confident evaluation of tiny channels and inner structures. A scanner like ZEISS METROTOM 1, which acquires data via X-ray images, captures the complete inside and outside geometry non-destructively and with high precision.

3D scanning and the future of electric motors

At Additive Drives, it isn’t just about building electric motors. It’s about shaping a sustainable future across different industries by developing highly efficient and powerful electric motors.