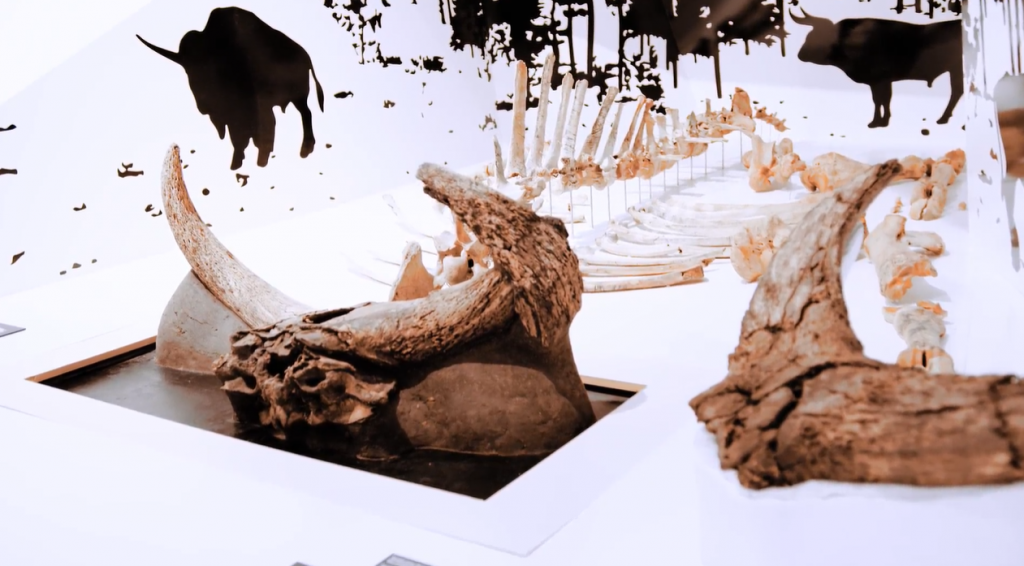

"The [...] preservation is a window into the past"

Jordi Serangeli

A past which lies back around 300,000 years to be precise. Due to dedicated work at the Museum and the archaeological excavation site nearby, conclusions about the flora and fauna can be made. In total more than 30,000 finds have been made already at the Museum of Research Schöningen.

The various applications of 3D metrology in archaeology

The areas of application for 3D scanning solutions are just as diverse as archeology itself. From archiving finds to digital sharing, scan systems are the first choice:

Preservation

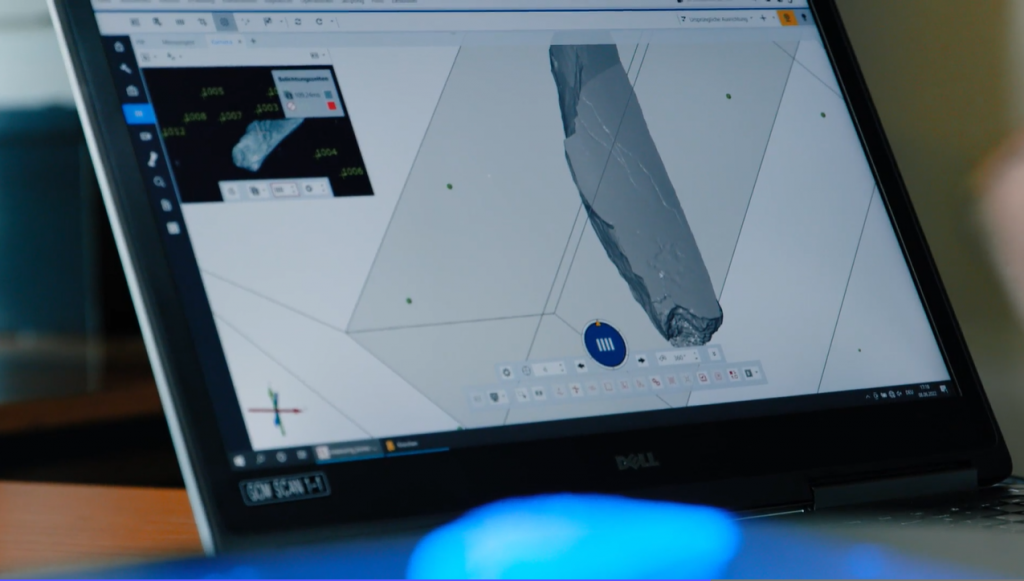

With the amount of archeological finds, it’s easy to lose track of them all. Scanning with the GOM Scan 1 helps employees organize their finds and get a quick overview of their collection. Instead of real archives, digital catalogs of scanned findings are created. The advantage: all necessary information of the part is available thru high-detailed scan data.

3D inspection

Of course, defects of the finds are to be assumed as well. With whom or what the living beings at that time came into contact, can be partly reconstructed by the surface inspection with 3D scanning systems like the GOM Scan 1. The build-in industrial standards, such as the GOM fringe projection technology and Blue Light Technology, deliver the foundation for detailed and accurate scans.

The laser scanner operates with the GOM Inspect software. It guides the user through the process, simplifies and accelerates the inspection. The generated mesh is the perfect base for further projects, like 3D printing and reverse engineering.

Reverse engineering

&

3D printing

High-resolution optical 3D measurement technology can be used to produce realistic copies of the original inform of 3D prints. The finds can be experienced directly – without sacrificing the detail of the parts.

For the reverse engineering processes, the ZEISS Reverse Engineering software comes in handy. It allows for an easy reversal of the development or production process from the product to the design drawing.

Archive & participation

Interested ones from all over the world get the chance to have a glance at the findings. Sharing of digital data is as easy as the push of a button and makes real-time knowledge transfer realizable.

Virtual exhibitions

Virtual exhibitions bring archelogy to life. To be able to present the findings to everyone, virtual exhibitions of the exhibits are used. Detailed illustrations and explanatory texts provide a realistic experience of history.

Get exclusive insights into the work of archeologists and the role of 3D scan technology.

Watch the new Maker Portrait now!

Museum of Research Schöningen: Archeology meets 3D Scan-Technology

300.000 years of history are archived at the Museum of Research in Schöningen. 3D metrology solutions help to collect detailed information about the findings. Whether the reconstruction of parts or precise surface inspection: Thus the GOM Scan 1 and the software solution allow an insight into the past, which is accessible to everyone. Learn more about the Museum: https://forschungsmuseum-schoeningen.de/home