過酷な条件下でも触覚測定が可能

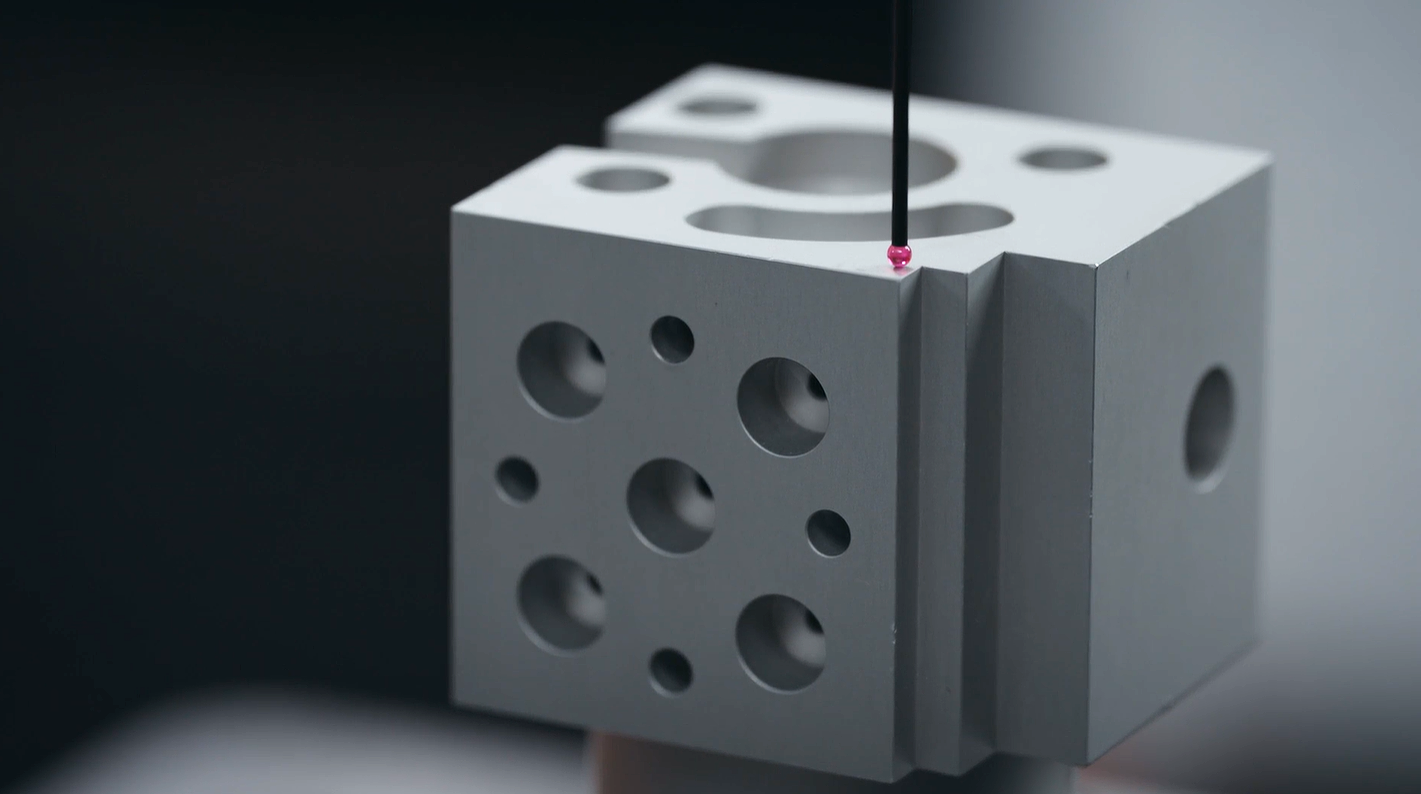

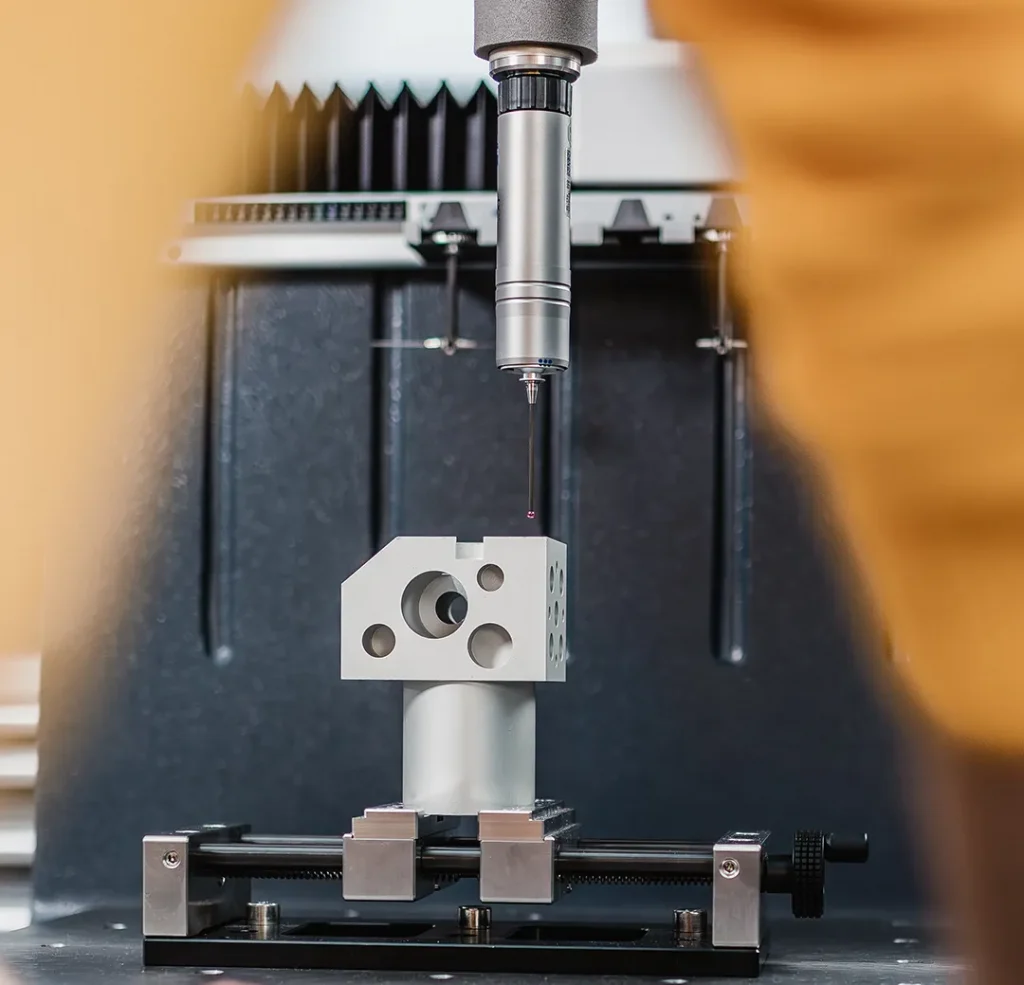

正確で、信頼性が高く、堅牢:ZEISS INSPECT搭載ZEISS DuraMax この三次元測定機は省スペースでありながら、測定容積が大きいため、限られたスペースに最適なソリューションです。測定ラボの管理された環境から、暖かく埃っぽい、あるいは湿度の高い現場まで、どんなに過酷な周囲条件下でも、正確な測定結果を提供します。

暖かく埃っぽい現場の接触ソリューション

どんな製造現場でも使用可能:30℃までの温度と70%の湿度に問題なく耐えられます。耐熱性に優れた材料を使用しているため、どんな周囲条件でも、常に再現性のある測定を保証します。もうひとつのプラス:埃や汚れによる影響を受けません。ZEISS INSPECT搭載ZEISS DuraMaxは特別なガイドカバーで保護されているため、ほとんどすべての作業場所で使用できる耐久性の高いソリューションです。

生産後すぐに検査

すぐに検査を開始することが可能。製造したばかりの部品を三次元測定機で測定できます。準備の必要がほとんどないため、わずかな時間で包括的な測定結果が得られます。

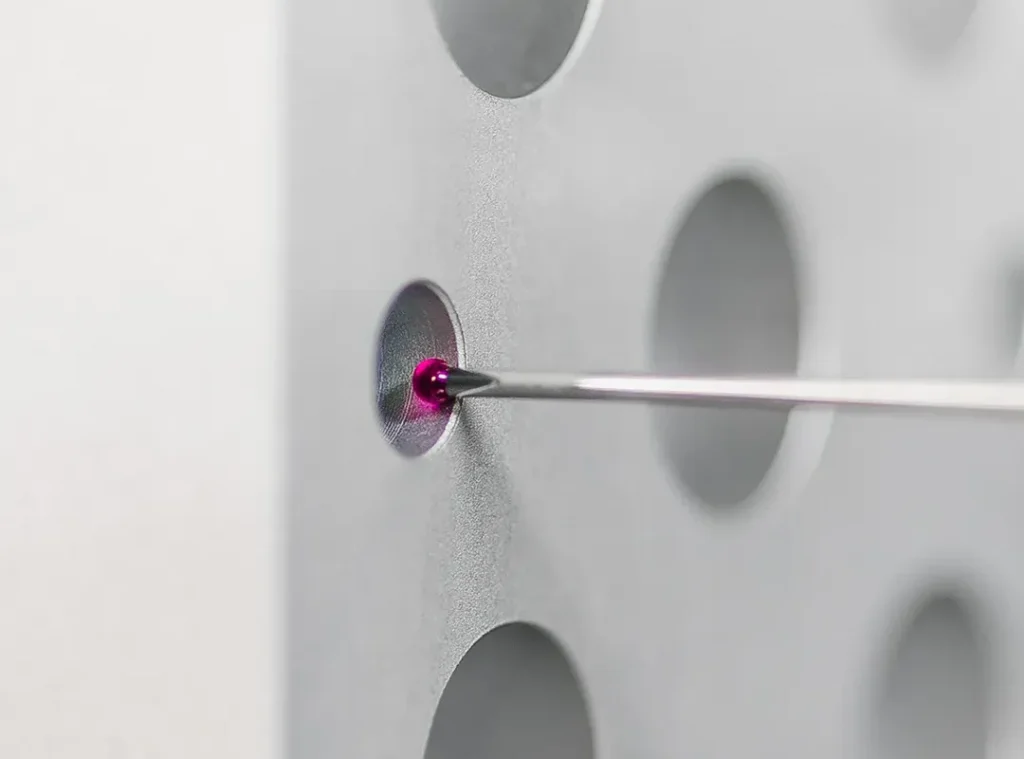

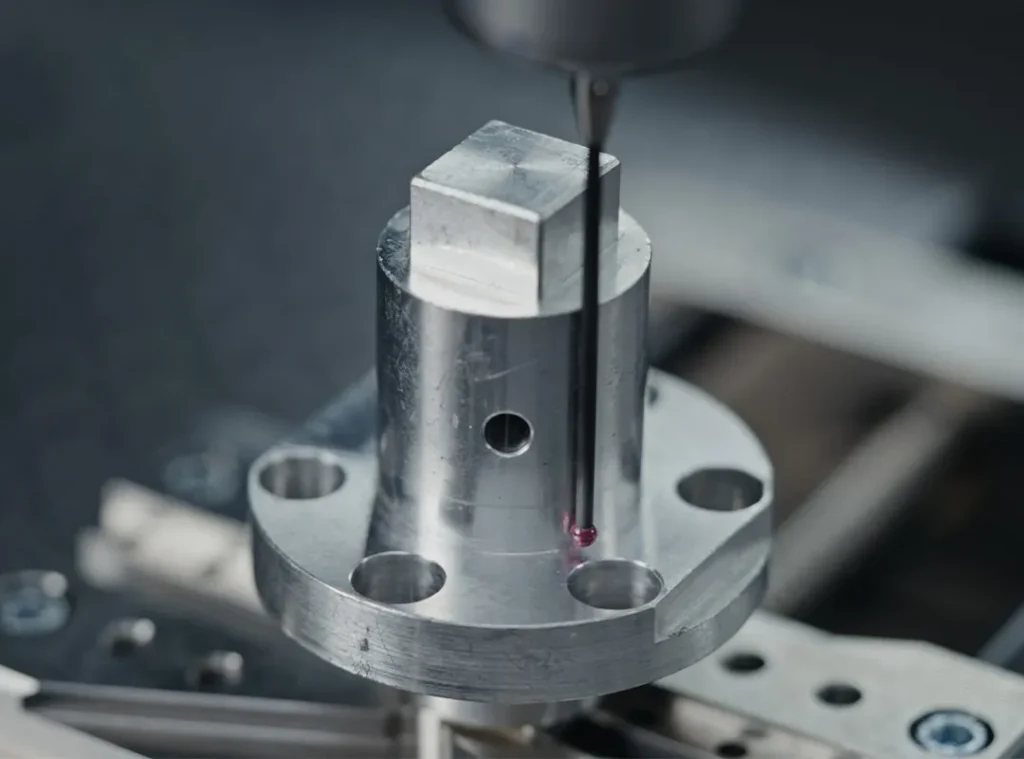

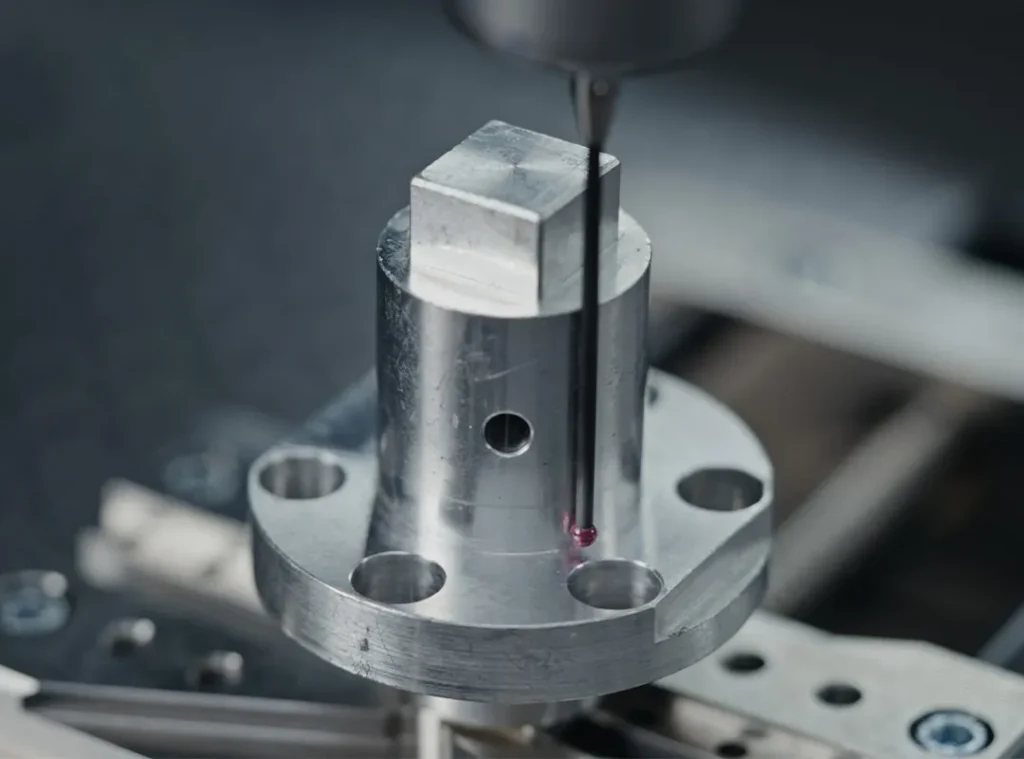

小さな対象物に最適

ZEISS INSPECT搭載ZEISS DuraMaxは細部まで測定可能。プローブの直径が小さいため、ドリリングの穴などの小さな形状を捉えることができます。実用的な長さのスタイラスにより、部品の奥深くまで届きにくい場所の検査が可能です。

その場で正確なデータの取得が可能

ZEISS DuraMaxを使用すれば、非常に正確で信頼性が高いデータの取得が可能。ISO10360に準拠して校正されているため、再現性の高い比較可能なデータが得られます。

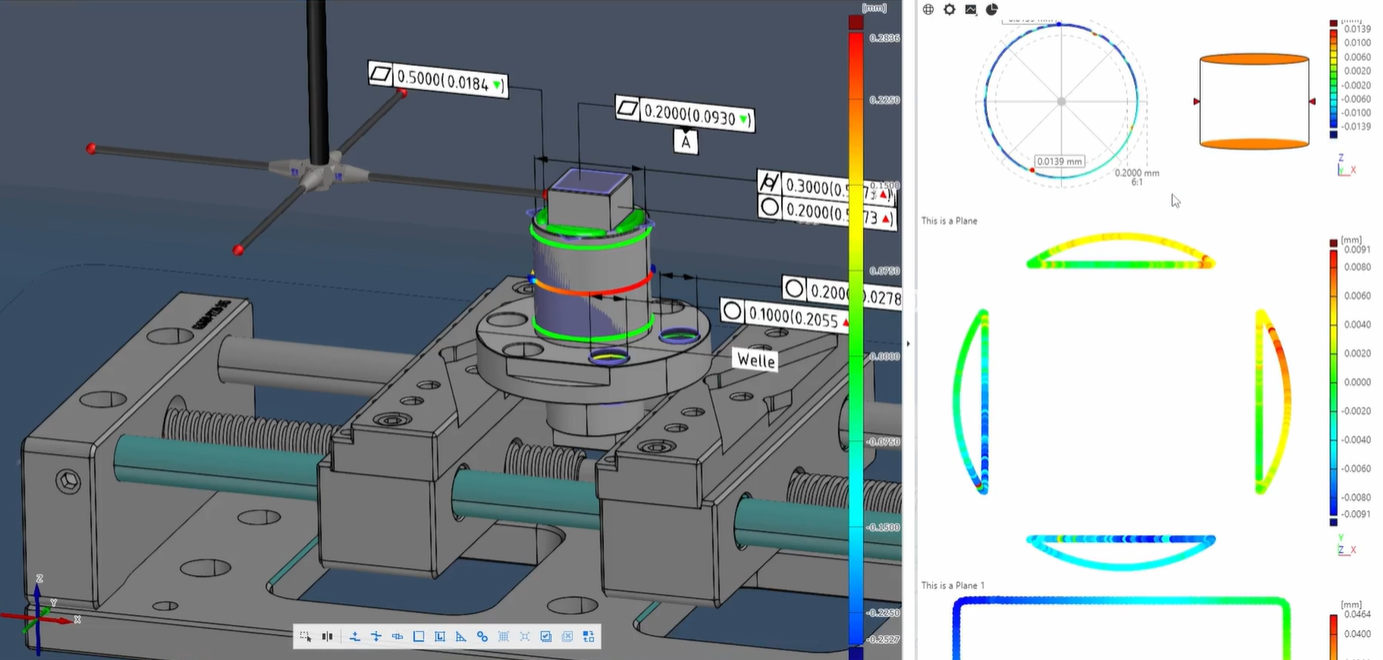

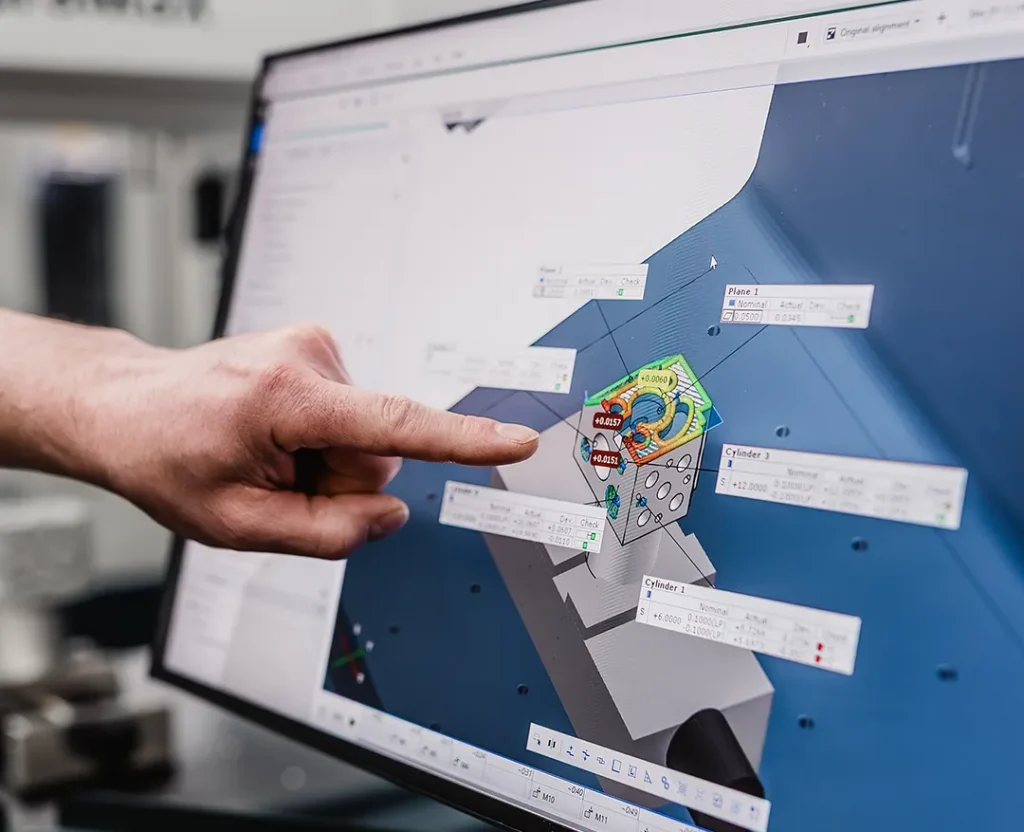

ZEISS INSPECTで 操作

ZEISS INSPECTソフトウェアで操作すると、三次元測定機が触覚測定タスクのための完全なソリューションになります。このオールインワン計測ソフトウェアを使用することで、計測値を直感的に評価し、レポートを作成することができます。高度な検査オプションのガイドにより、ワークフロー全体を通して測定データそのものと同程度正確な評価が得られます。

特徴

測定スピードが速い

ZEISS DuraMaxのZEISS VAST XXTセンサーはスピードと精度を兼ね備えています。 シングルポイント測定では、可能な限り高い精度を実現。より複雑なタスクでは、センサーが表面や輪郭のスキャンの高速化を可能にします。高密度測定により、寸法や形状の評価を可能な限り詳細に行うことができます。

ガイド付き部品プログラミング

ZEISS INSPECTが部品のプログラミングのあらゆるステップをガイドします。一度プログラミングすれば、簡単に繰り返し測定が行えます。ZEISS DuraMaxの測定空間に部品を置くだけで、測定が開始されます。

人間工学に基づいたワークフロー

ワークフローのさらなる改善:部品を3方向から乗せることが可能。巧みな設計により、常に測定空間への高いアクセス性と視認性が確保されています。

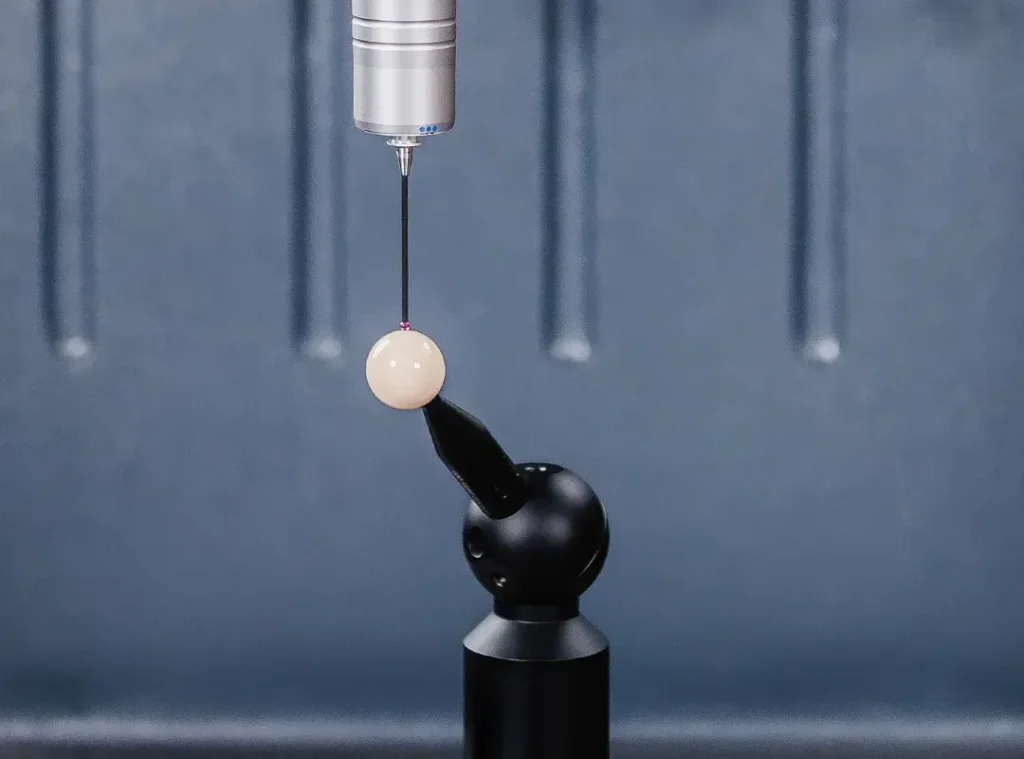

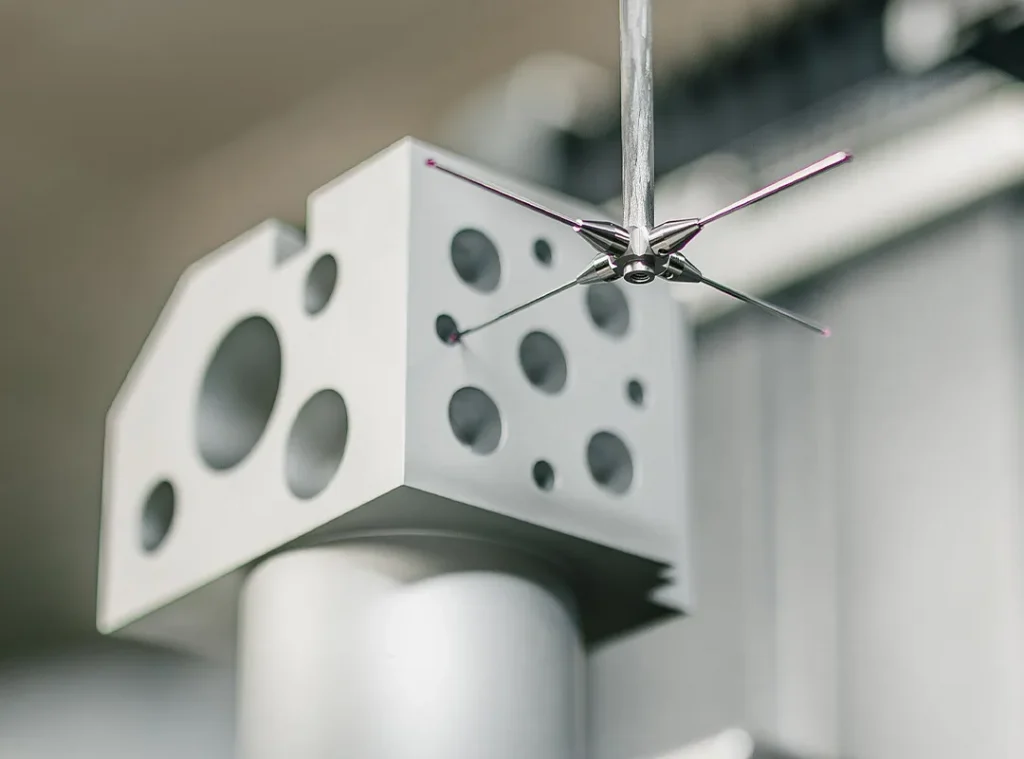

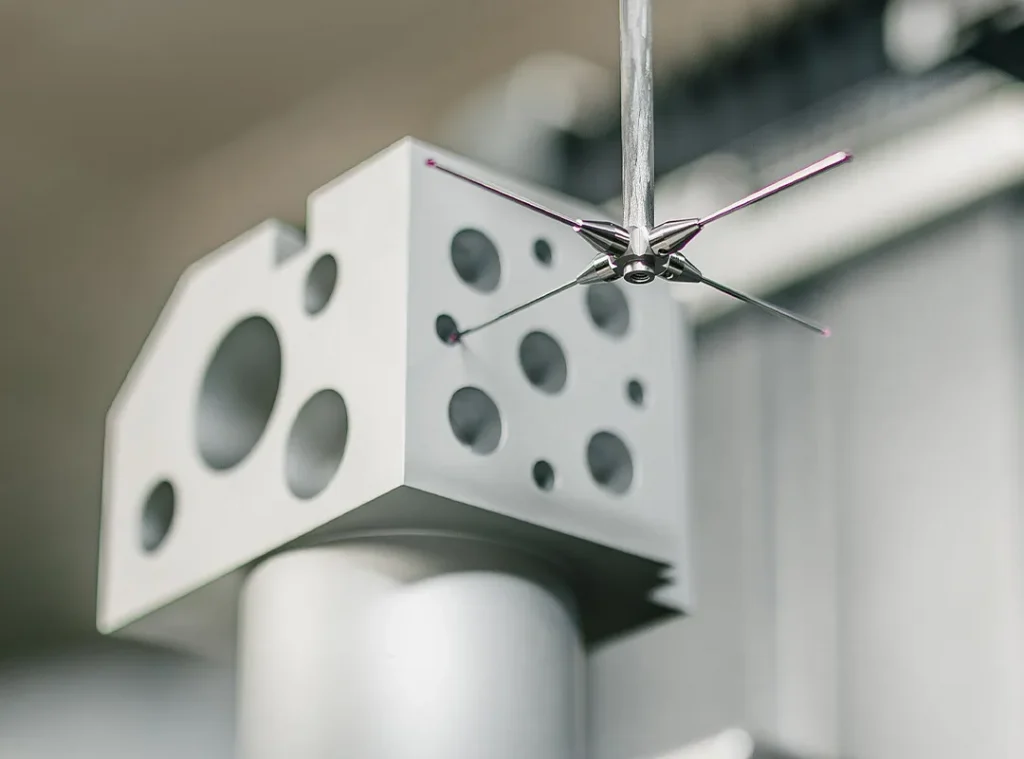

自動スタイラス交換

ZEISS DuraMaxはマルチセンサーラックを装備。個々の検査に応じて、シームレスにスタイラスを切り替えることができます。この自動交換により、ワークフローが効率化されるだけでなく、可能な限り正確な測定結果が得られます。

省スペース、大きなインパクト

設置面積が小さいにもかかわらず、測定容積が大きく、さまざまなサイズの部品を検査することができます。

設置面積が小さいため、運用コストを最小限に抑えながら、高品質な製品の製造に専念することができます。

アクセサリ

どんな検査にでも対応可能

ニーズに合わせて選択が可能です。使用場所に応じて、2種類のベースからお選びいただけます。2セットのスタイラスを使用すれば、それぞれの測定条件に簡単に適合させることができます。簡単に部品を入れ替えたり、大量の部品を検査したりするには、パレットが最適です。

幅広い用途

産業

- 医療/製薬

- 航空宇宙

- エレクトロニクス

- プラスチック産業

- 自動車

- アフターマーケット

- 金属製品製造

プロセス

- フライス加工

- ドリリング

- ターニング

- 研磨

- 付加製造

- 射出成形

材料

- 金属

- セラミックス

- 硬質プラスチック

- 複合材料

部品

- ハウジング

- CNC機械加工部品

- シャフト

技術データ

ZEISS DuraMax

(ZEISS T VA 1) E0/E40 (μm)

(ZEISS T VA 2) E0/E40 (μm)

(1) ISO 10360-2:2009に準拠したE0/E40 (μm) MPE

もっと見る

i

Please select the topic you seek more information aboutDuraMax with ZEISS INSPECT: The basics of tactile measurement technology

Learn the basics of tactile measurement technology. Our CMM expert Florian gives an overview of tactile inspections and the features of our CMM ZEISS DuraMax with ZEISS INSEPCT.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

DuraMax with ZEISS INSPECT: The setup

You just got your CMM and directly want to start with your tactile inspection task? Watch this Getting Started to learn how to set up ZEISS DuraMax with ZEISS INSPECT for fast and accurate tactile inspections.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

DuraMax with ZEISS INSPECT: First use of ZEISS INSPECT

A software that offers easy operation of your CMM and simplifies the evaluation of tactile measurement data? In this Getting Started, Florian gives insights into ZEISS INSPECT software for CMMs and highlights important features, like the VMR.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

DuraMax with ZEISS INSPECT: Assemble and qualify stylus systems

Stylus systems are crucial for tactile data generation. Choosing the right styli for your tactile inspection and qualifying them properly have a major impact on the data quality. Learn here how to assemble and qualify your stylus systems for the CMM ZEISS DuraMax with ZEISS INSPECT.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

DuraMax with ZEISS INSPECT: Your first tactile measurement

Starting your first tactile inspection with ZEISS DuraMax with ZEISS INSPECT is easy. Watch this Getting Started to learn more about measurements with a CMM and recieve your precise tactile data in a matter of moments.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

DuraMax with ZEISS INSPECT: Complex part measurement

CMMs are made for inspecting complex geometries and small features at the highest accuracy possible. In this video you will learn the basics of complex parts measurements, including tips to simplify part programming.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

DuraMax with ZEISS INSPECT: Reports for series measurements

Give more meaning to your tactile measurment data by professional reports. In this Getting Started, Florian shows you what ZEISS INSPECT software has to offer in terms of creating comprehensive resports and how to set up your reports for tactile series inspections with ZEISS DuraMax with ZEISS INSPECT.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com