Descripción general de la tecnología

La tecnología adecuada para tu aplicación

Escaneo 3DEscaneo láser

El escaneo láser se centra en aplicaciones en el lugar donde la portabilidad es clave. Las líneas láser se proyectan sobre la pieza moviendo el escáner alrededor de ella para capturar datos 3D de alta precisión.

ZEISS T‑SCAN hawk 2

Portátil, fiable y fácil de usar: ZEISS T-SCAN hawk 2 está diseñado para mediciones de alta precisión donde las necesites, incluso en espacios estrechos y de difícil acceso.

Escaneo 3DProyección de franjas

Con la proyección de franjas, un patrón de luz estructurada se proyecta rápidamente sobre la pieza. Esta tecnología de escaneo 3D ofrece la máxima precisión y nivel de detalle.

GOM Scan 1

El compacto y fácil de usar GOM Scan 1 proporciona mallas precisas y detalladas para grandes ideas.

ATOS Q

ATOS Q combina velocidad y precisión para tareas complejas de medición e inspección industrial.

ZEISS ScanPort

Gracias a su diseño móvil y flexible, ZEISS ScanPort te ofrece escaneo 3D semiautomatizado donde lo necesites. Es una solución todo en uno para mediciones automatizadas de alta precisión.

Rayos X

El escaneo por rayos X genera imágenes 3D de estructuras internas y externas. Proporciona una solución no destructiva para inspeccionar defectos ocultos y estructuras, así como para examinar piezas ensambladas.

ZEISS METROTOM 1

Control de calidad de fuera hacia dentro. ZEISS METROTOM 1 es una solución fácil de usar que captura datos 3D precisos sin necesidad de preparación de la pieza.

Máquinas de medición por coordenadas

Mediante el uso de una sonda táctil que toca físicamente la pieza, las máquinas de medición por coordenadas (CMM) recopilan coordenadas precisas de la superficie de un objeto. Las CMM son muy precisas y se utilizan para medir y verificar geometrías complejas y formas intrincadas.

ZEISS DuraMax con ZEISS INSPECT

ZEISS DuraMax con ZEISS INSPECT es una máquina de medición por coordenadas robusta para inspecciones táctiles fiables. Captura datos precisos incluso en entornos adversos.

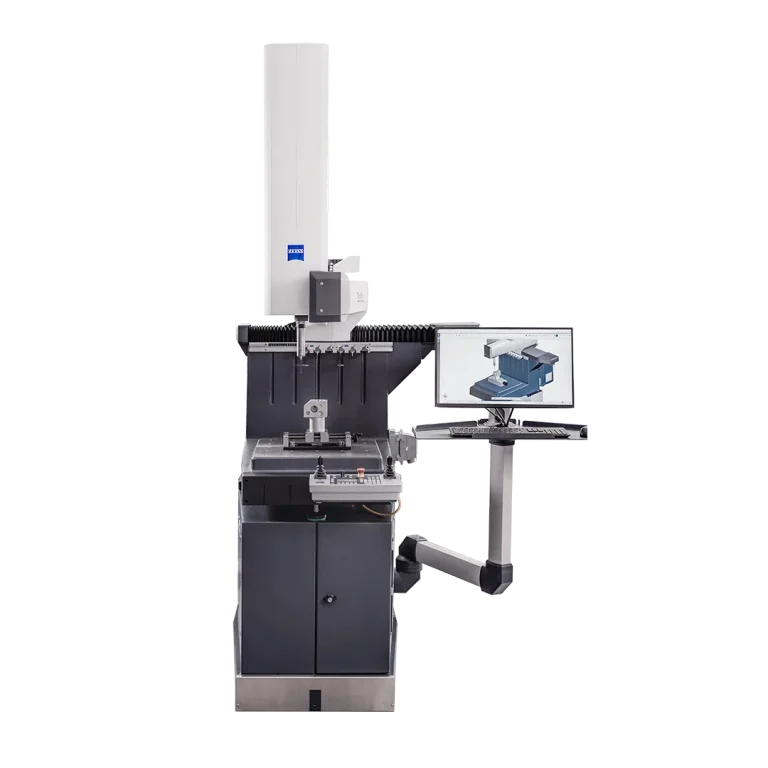

Máquinas de medición por visión

Las máquinas de medición por visión (VMM) utilizan cámaras e iluminación variable para capturar imágenes de alta resolución de una pieza. La medición sin contacto analiza de manera fiable los detalles finos de partes delicadas o planas.

ZEISS O-DETECT con ZEISS INSPECT

La combinación de mediciones ópticas y táctiles convierte a ZEISS O-DETECT con ZEISS INSPECT en un verdadero todoterreno para una amplia variedad de tareas de medición en distintos sectores.

Software

Nuestras soluciones de software todo en uno y centradas en el usuario simplifican los flujos de trabajo de metrología y respaldan el escaneo, la inspección, el reverse engineering y la elaboración de informes para una amplia variedad de aplicaciones.

ZEISS INSPECT

Con ZEISS INSPECT puede gestionar sin esfuerzo todas las tareas del proceso de inspección, con un solo software. Empiece ahora con un amplio conjunto de funciones de inspección gratuitas. Empiece ahora con un amplio conjunto de funciones de inspección gratuitas.

ZEISS INSPECT versión pro

La versión pro de ZEISS INSPECT ofrece funciones avanzadas y aplicaciones con características aún más especializadas para diferentes sectores.

ZEISS REVERSE ENGINEERING

Convierte fácilmente tus datos de escaneo 3D en un modelo CAD de alta precisión en solo unos pocos pasos guiados con nuestro potente software ZEISS REVERSE ENGINEERING.