When the inside matters

ZEISS METROTOM 1 stands for ease of use, precise 3D data and quality control from the outside in.

One scan, deep insights

Fast, intuitive and highly precise

A compact and easy-to-operate system to capture the data for your tasks

The simple-to-operate system enables various users to start the measuring process and capture precise data. Characterized by its compact dimensions, METROTOM 1 fits easily into your space. Get started with your inhouse measurements and inspections in just one step by pushing the button. To keep your maintenance low, the smart and compact solution comes with a closed x-ray tube.

Capture 3D data without part preparation

With METROTOM 1 you can inspect internal structures and defects using non-destructive scanning. No part preparation is needed before starting the measurement process. While you scan the next part, you can inspect or reverse engineer the previous one.

Multiple part scanning

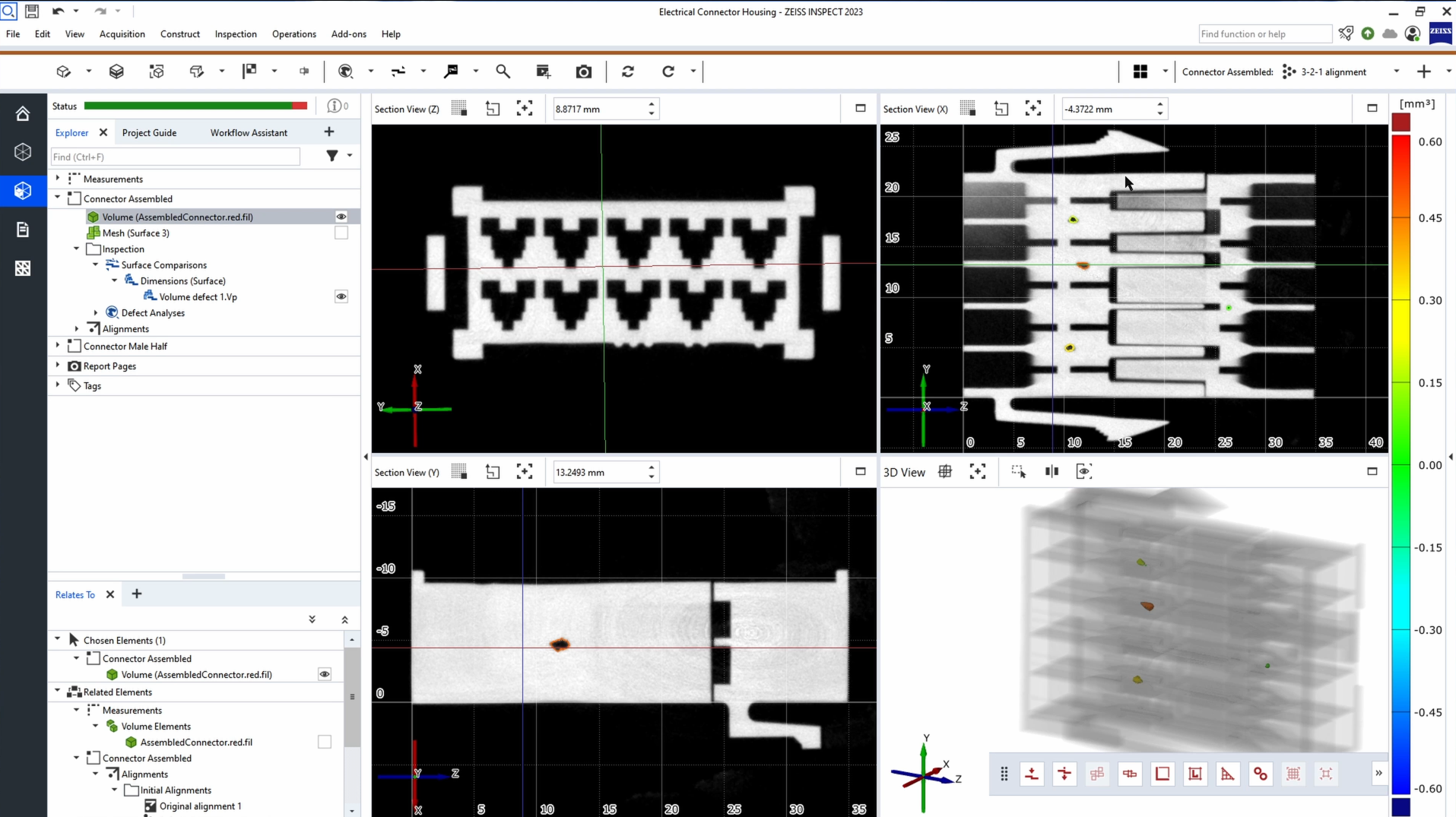

Measuring multiple parts at the same time is one of the most efficient features of METROTOM 1. The formula is simple: high quantities with optimum use of the measuring volume. The result: faster scanning time per part without compromising on quality. ZEISS INSPECT automatically separates and evaluates the individual parts so that results are quickly available as a report.

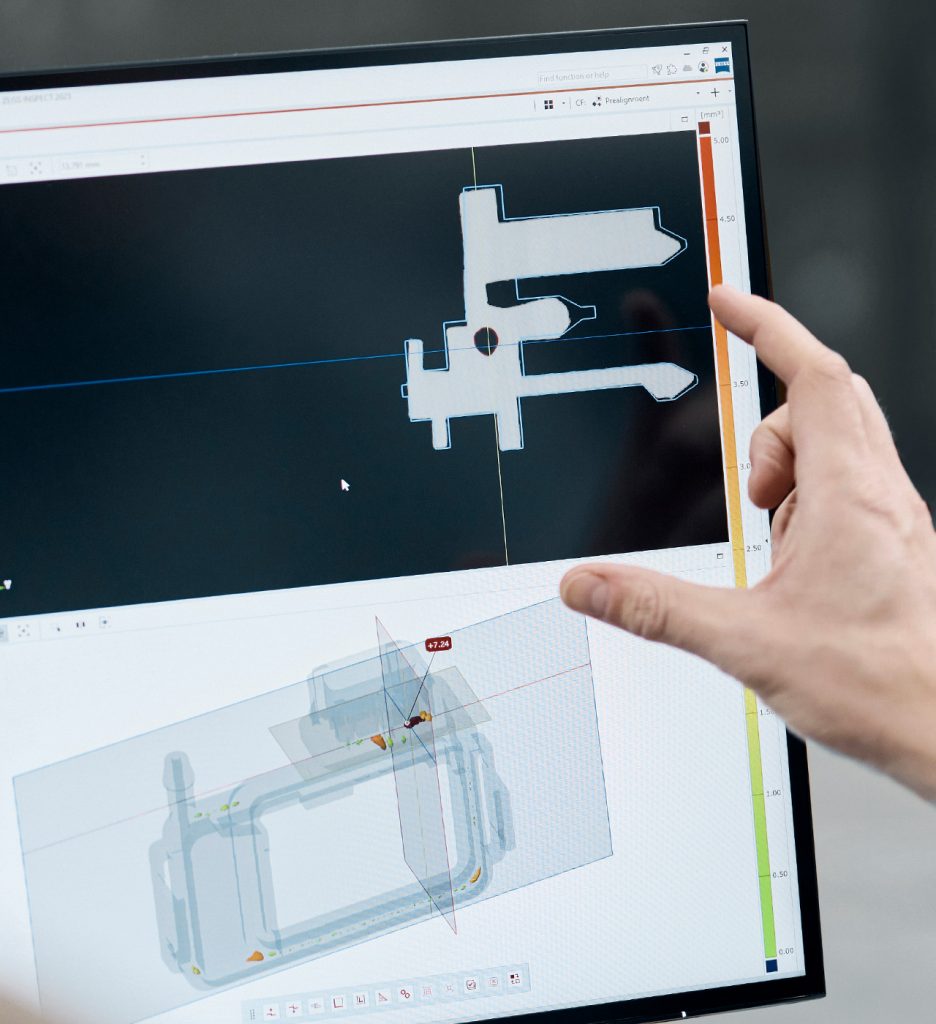

Check internal structures and defects

The METROTOM 1 with ZEISS INSPECT guides you step-by-step through the measurement process. With volume visualization and inspection of your scan data, you can discover all dimensions of your parts, even the hidden ones. By scanning all internal and external structures, parts can be easily reversed.

Easy and efficient. With just one scan. METROTOM 1 supports you with:

- 3D scanning of small to medium components

- Accurate measurement

- Quality inspection and assurance

- Deep analysis of rejects

- Checking components against their CAD

A smart all-in-one concept

Features

Active temperature balancing for precise results

Highly accurate measurement results

Every METROTOM 1 is checked for accuracy – during production and additionally after the on-site installation. The accuracy check is done using a calibrated and DAkkS-certified acceptance artifact. The scanner can be recalibrated by you at any time using the calibration object on site.

Digitally guided by ZEISS INSPECT for optimal results

Different applications have different requirements

Measure everything easily within a measuring volume of 165 x 140 mm. The measuring volume can be fine-tuned digitally. At the same time, you can adjust the resolution to speed up your process resulting in fast scanning times according to your needs.

Accessories

Inside the METROTOM 1

The compact system is packed with:

- Calibration object

- Continuous scan mode

- Operation station

- ZEISS INSPECT

- 2.5k detector developed by ZEISS

- 160 kV X-ray source

- Temperature controlled cabinet

- Active temperature control

- 360 Degree Automatic Rotation Table – 5kg part capacity

Applications

Limitless use cases

A wide range of applications

- Nominal-actual CAD-to-part comparison

- Dimensional measurements

- Section inspection at any depth of the part

- Analyse wall thickness distribution

- Functional dimensioning for first article

- Ensure correct first part by scanning multiple samples produced with different parameters

- Reducing the number of iterations in your process

- Monitor production process with fast inspection of multiple parts

- Actual capture following tool approval

- Warpage compensation of component

- Examine even high demanding products like transparent objects and soft polymers

- Functional and error analysis of assemblies

- Non- destructive material defect analysis e.g. blowholes, pores or cracks

- Reverse engineering of existing parts or part geometries

- Validate engineered designs

Technical Data

Do you want to find out more?

Discover more

i

Please select the topic you seek more information aboutMETROTOM 1: The Setup

The 3D scanner ZEISS METROTOM 1 is powered by CT technology and allows you to inspect internal structures that can’t be detected with tactile or optical measuring systems. Sounds interesting? In this Getting Started video Aysel and John will teach you how to set up the hardware. Find out how to power up. Discover the scanner’s control hardware with all its switches, buttons and functions. Then learn how to connect the solution to the software ZEISS INSPECT and warm up the X-ray tube.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

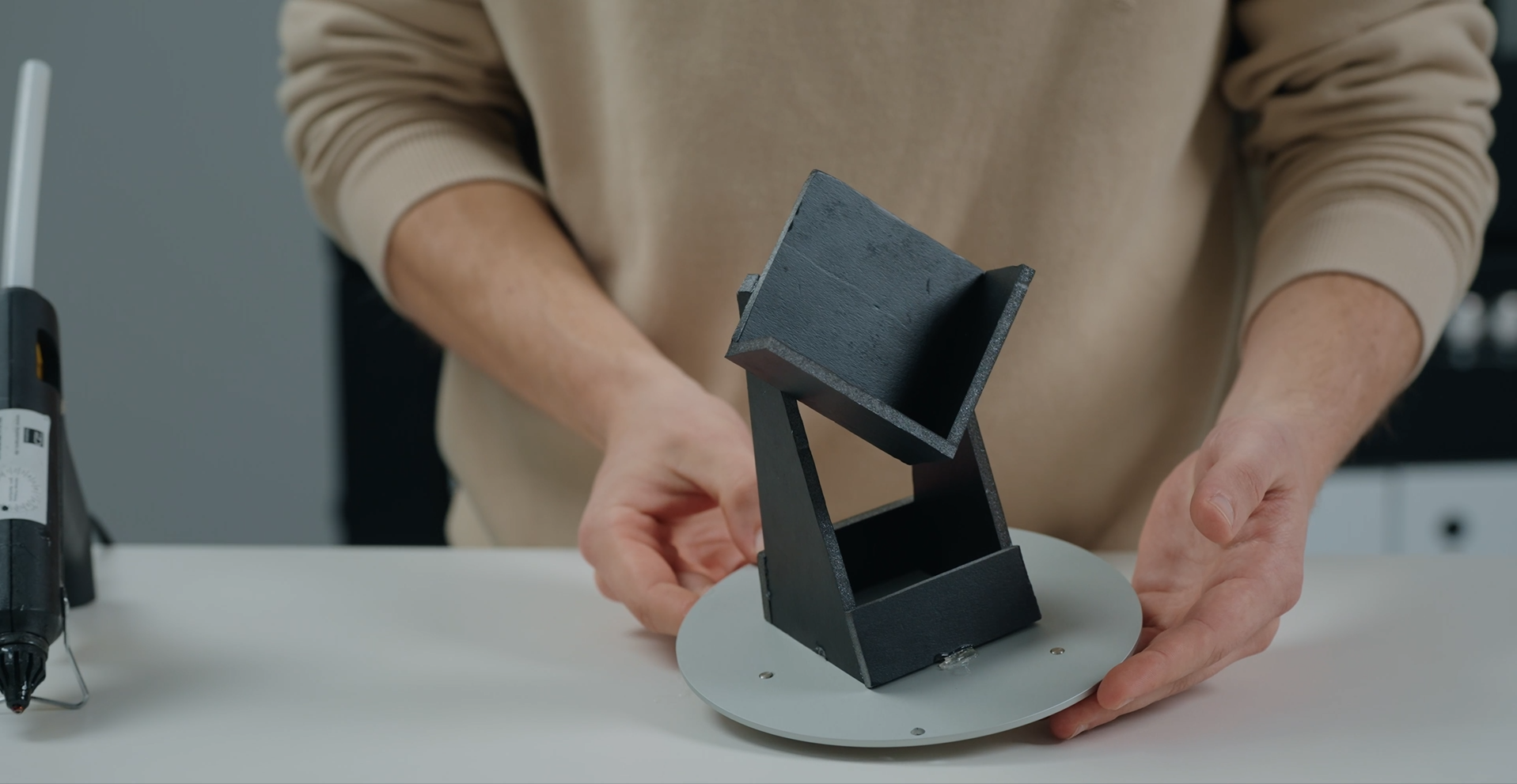

METROTOM 1: Easy part fixture

So you got yourself the 3D scanner ZEISS METROTOM 1 – powered by CT technology – and want to learn how to fix a part so it won’t move during the scan? In this Getting Started video Aysel and John will show you a few quick and cost-efficient tricks for creating the perfect part fixture. Watch the two 3D experts as they get crafty with insulation foam and hot glue before placing their part on the fixture plate and locking it into the rotation table inside the system.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Introduction to ZEISS INSPECT

ZEISS METROTOM 1 – powered by CT technology – is yet another 3D scanning solution that fully reaches its outstanding potential once connected to the software ZEISS INSPECT. Follow Aysel and John, as they take you into ZEISS INSPECT via the ZEISS Quality Suite, and get a quick tour around the four different workspaces, dedicated to scanning, inspecting, reporting and mesh editing.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Scanning single parts

You want start your first 3D scan with ZEISS METROTOM 1 so you can inspect the internal structures of a part via CT technology? Then watch Aysel and John’s Getting Started video first: Their step-by-step tutorial takes you through the basic scanning strategy of scanning a single, transparent plastic part. You’ll learn about all the adjustments to be made on the METROTOM 1 before the scan – including the adjustment of the filter wheel and the x-ray tube parameters voltage, power and exposure time. Just follow them along – it’s easy.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Scanning multiple parts

The 3D scanner ZEISS METROTOM 1 – powered by CT technology – is perfect for scanning multiple parts at once, as it seriously reduces scan times. Interested? Then watch Aysel and John’s tutorial. Learn how to prepare the parts for 3D scanning, discover how to set up the software – and experience its simple, built-in separation tool: for separating out the batch volume into smaller volumes for each individual part.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

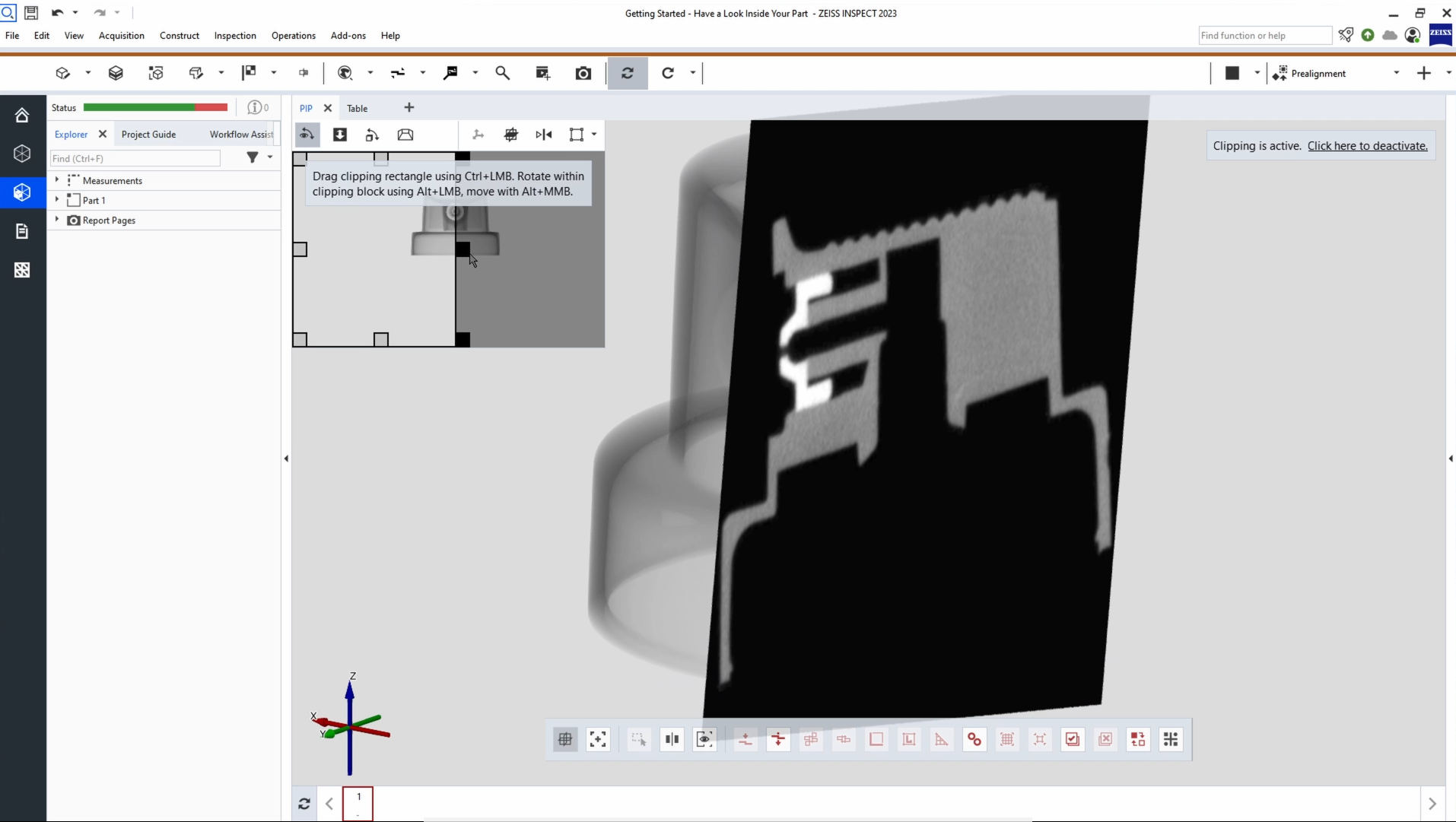

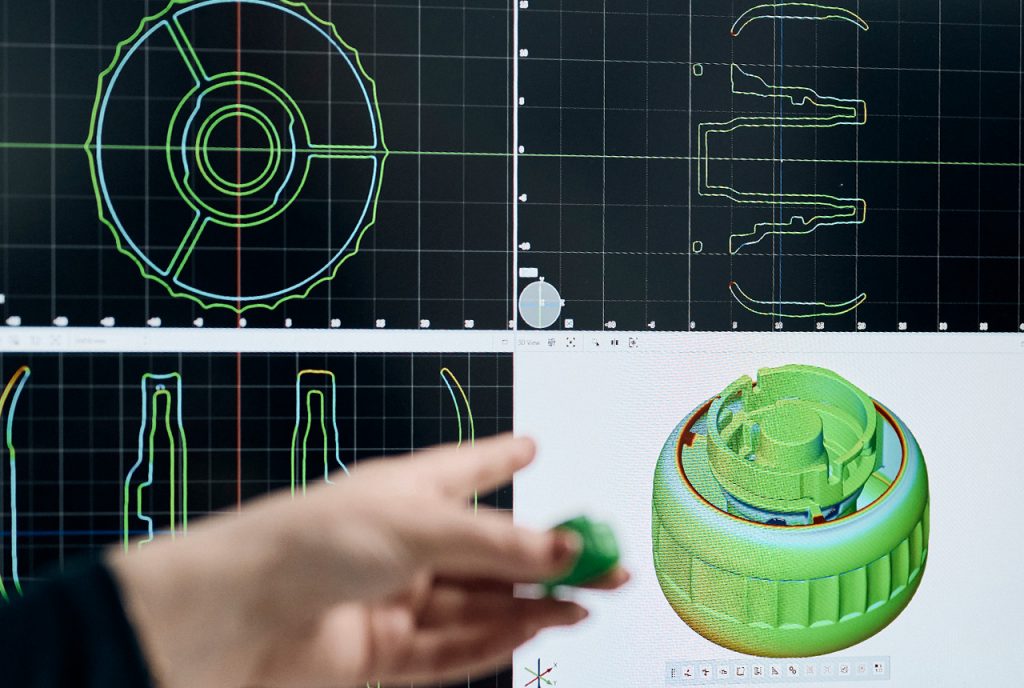

METROTOM 1: Easy volume visualization

When combined with the software ZEISS INSPECT, the 3D scanner ZEISS METROTOM 1 offers incredible advantages for the inspection of internal defects – and John and Aysel know all the visualization tricks. Follow their tutorial to learn about slicing through a part in order to look inside. Scroll through parts with the clever picture-in-picture view. Choose the multi-view function for a view of all three directions. And get several insights at a single glance by making the mesh and CAD visible, too.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

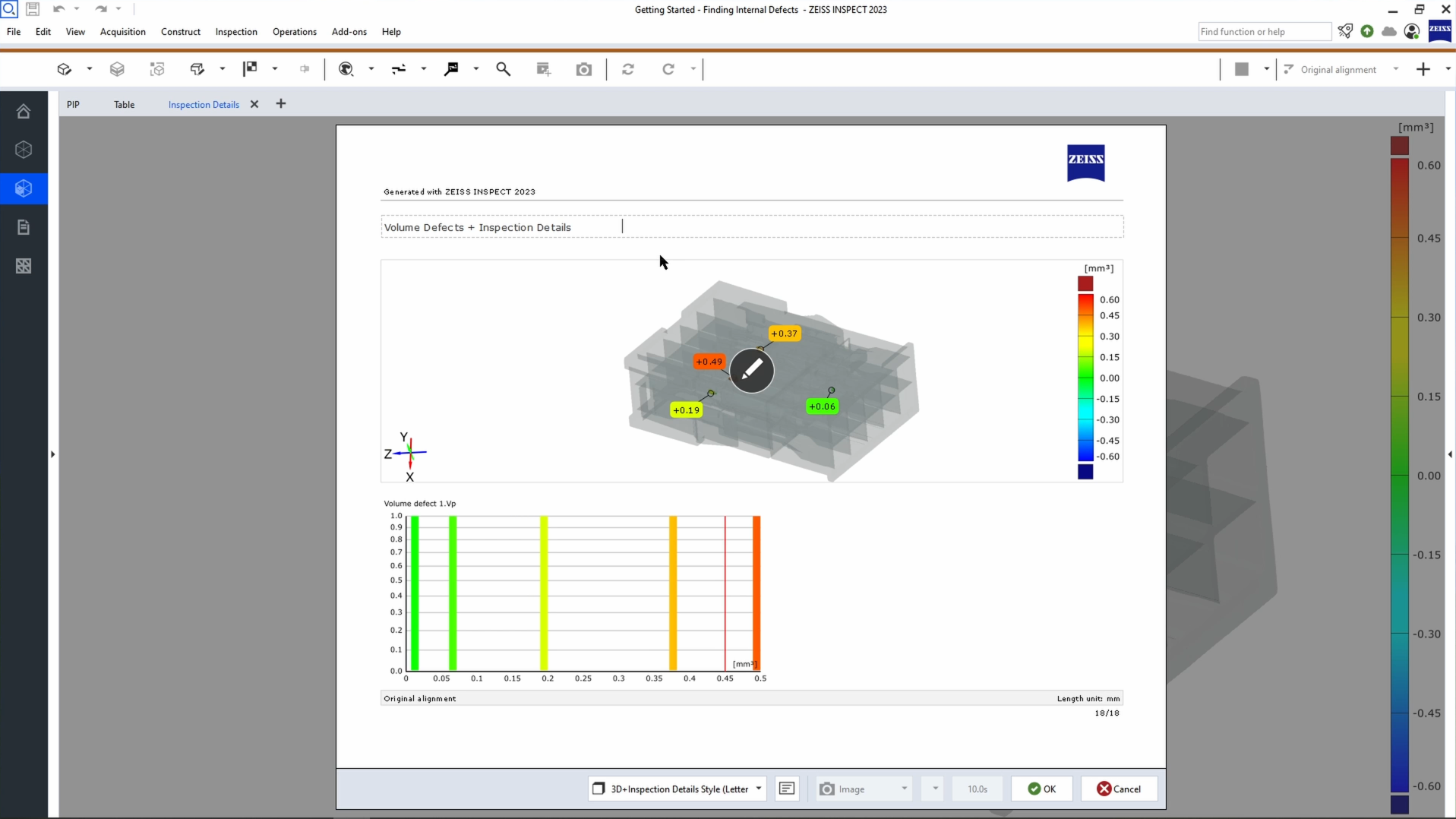

METROTOM 1: Easy internal defect inspection

You’re looking for a solution to help you locate and classify internal part defects? Then ZEISS METROTOM 1 – powered by CT technology – is the perfect solution and this video teaches you how it’s done. Learn how to do automated, high-quantity internal inspections on the digital twin of any part. Take a look at all aspects of a defect – from porosity percentage or defect volume to defect length or defect distance to the surface of the part.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Quick & easy calibration

In this video, Aysel and John will show you how to calibrate the 3D scanner ZEISS METROTOM 1. The solution comes with a calibration object and fixture device so you can recalibrate at any time. Good news: The software ZEISS INSPECT guides you through the process. After that, your METROTOM 1 is ready for 100 % accurate 3D scanning.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

METROTOM 1: Automated parameter selection

What makes the use of your 3D scanner ZEISS METROTOM 1 even more convenient? Automated parameter selection: a standard function in ZEISS INSPECT. Sounds interesting? In this video you’ll learn how to let the solution calculate suitable parameter settings for you – based on part shape, thickness, density and desired scan resolution. Time for you to sit back and wait for the magic to happen.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

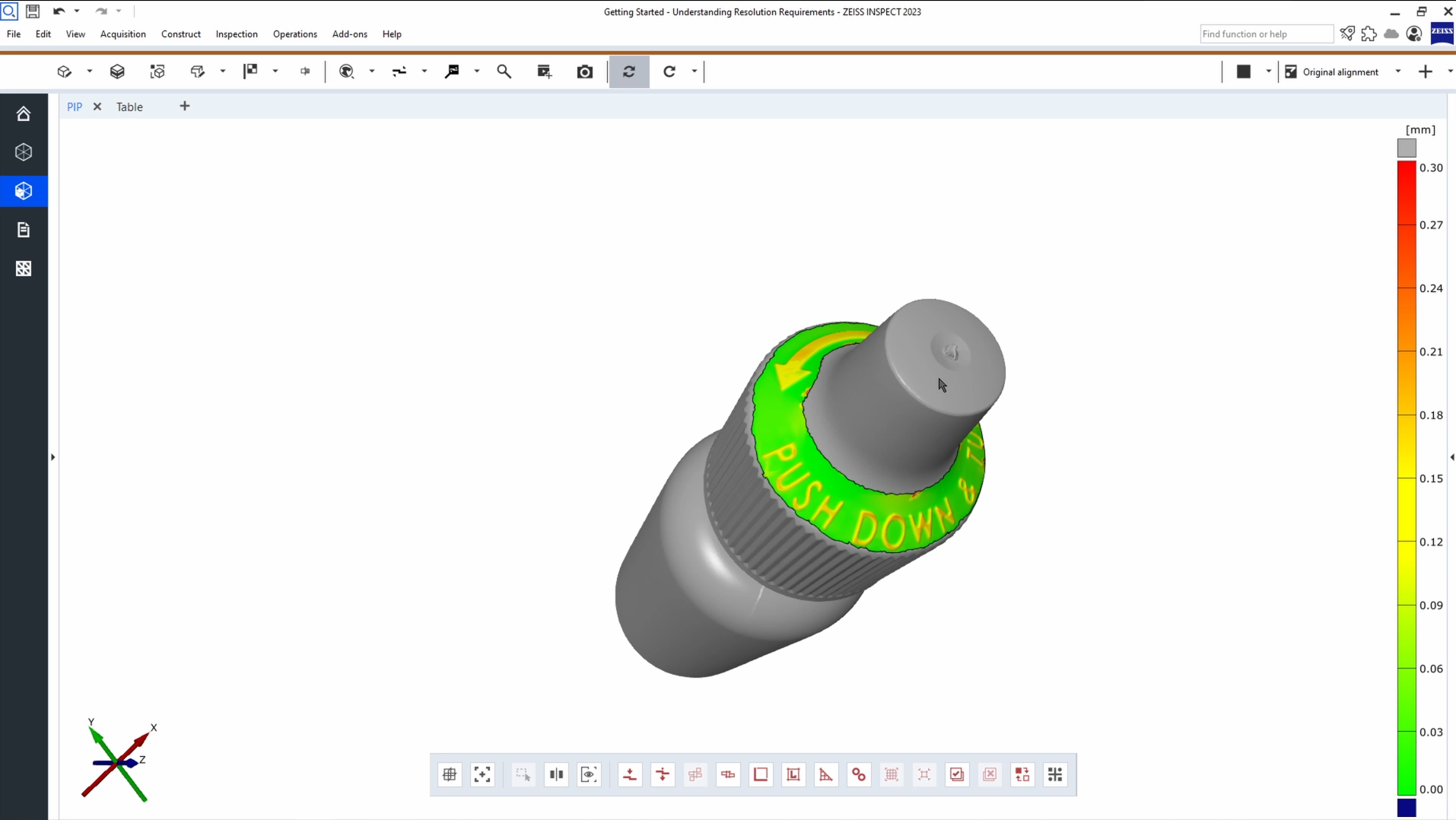

METROTOM 1: Introduction to scan resolution

The 3D scanner ZEISS METROTOM 1 – powered by CT technology – is a versatile system with a useful set of pre-defined scan resolutions to cover a wide range of objects and measuring tasks. In this Getting Started video you’ll get an introduction to scan resolution requirements. You’ll learn how to calculate a suitable resolution with a simple rule of thumb. You’ll discover the advantages of 3D scanning in a lower or higher resolution. And you’ll discover the system’s most commonly used resolution settings.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

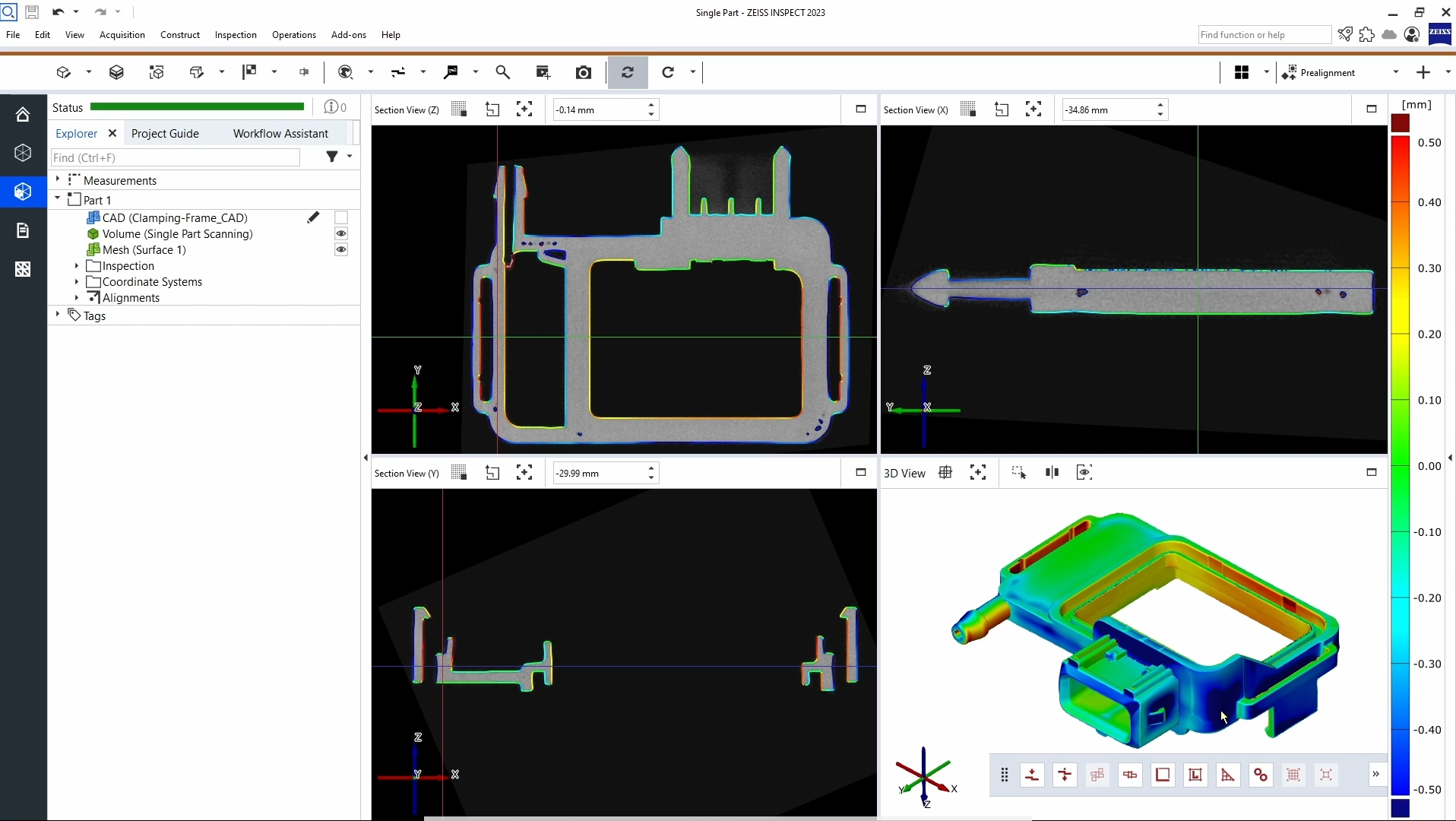

METROTOM 1: Part inspection with CAD data

In this Getting Started Aysel and John will show you how to inspect a 3D scan of your METROTOM 1 using not only scan data but CAD data, too. Find out about the benefits of 3D inspection with CAD data. Discover how to join and align a scan mesh with a CAD file. Learn about the software’s surface comparison, distance inspection and GD&T analysis function. The cherry on top: all inspections are documented in the report workspace – making reporting extra easy.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

Discover our newest video sessions

Follow us

Sessions

Solutions

Digital Events

Subscribe to our newsletter

- Privacy Policy

- Imprint

- ©2023. All Rights Reserved