Multitasking semplificato

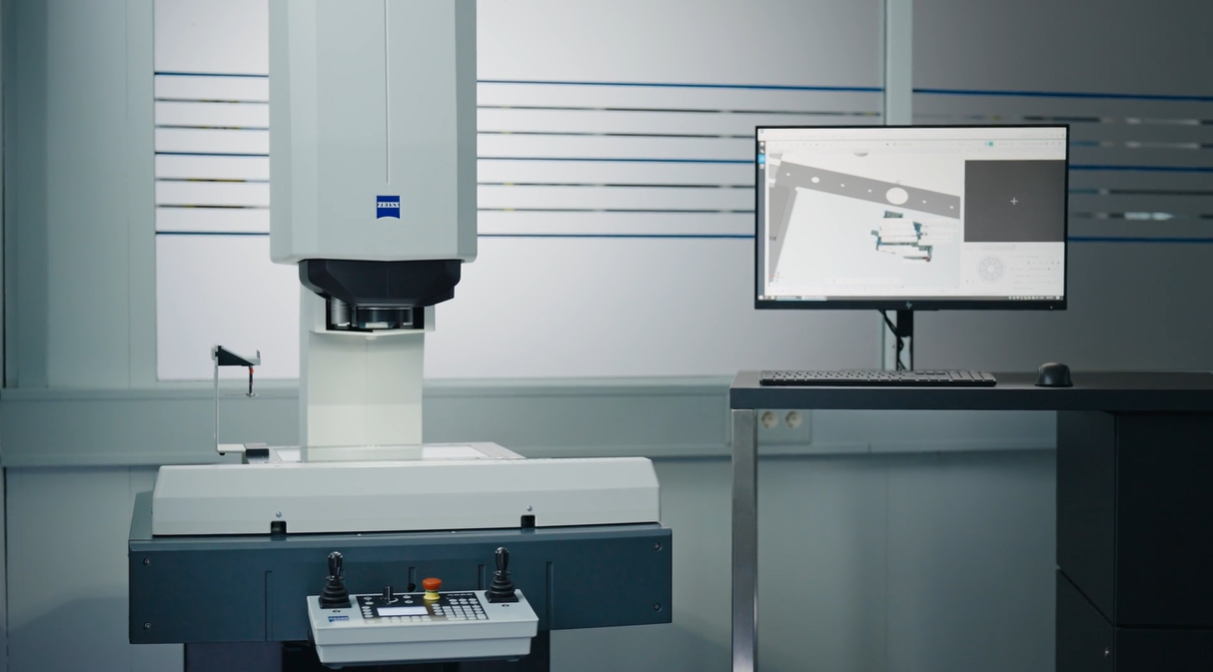

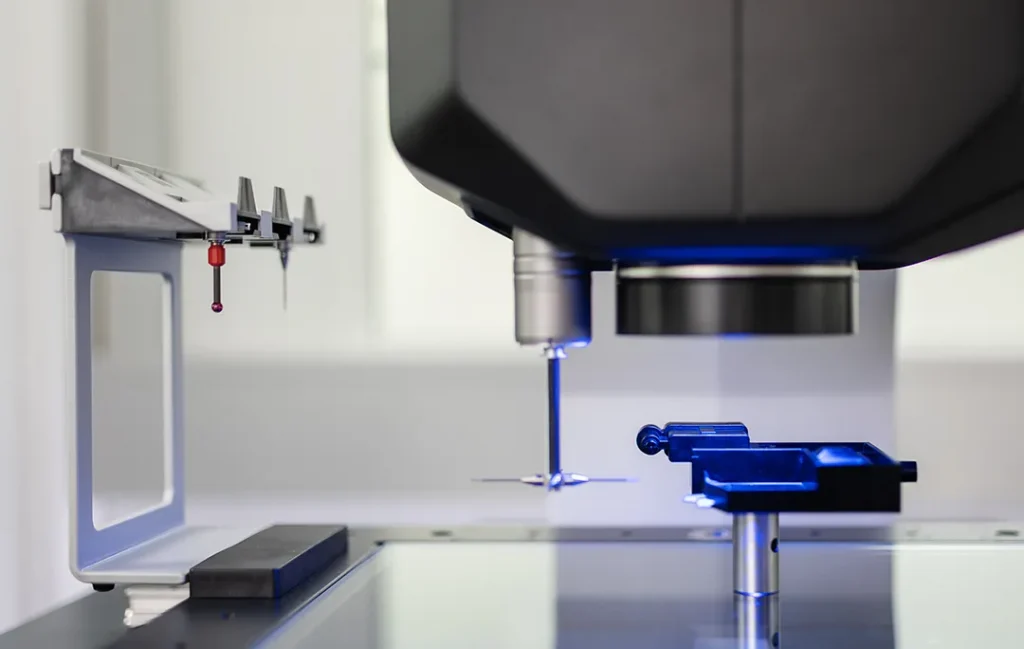

La combinazione di misure ottiche e a contatto fa di ZEISS O-DETECT con ZEISS INSPECT un asso del multitasking, adatto per un’ampia gamma di attività di misura in vari settori.

La macchina di misura ottica è progettata per una garanzia di qualità ottimale grazie a immagini di alta qualità. Ampliate l’ispezione ottica in modo semplice includendo la misurazione a contatto con i sistemi a stilo disponibili per ZEISS O-DETECT.

Due fotocamere che vedono tutto

Questa soluzione è equipaggiata con due fotocamere, che consentono di avere sempre una visione d’insieme. Una fotocamera a colori panoramica integrata individua il pezzo più rapidamente per iniziare la misurazione. L’ottima ottica ZEISS della fotocamera di misura e ZEISS Digital Zoom offrono un ampio campo visivo con risoluzione elevata – per una maggior efficienza e per acquisire più dettagli. In combinazione con la tecnologia di elaborazione delle immagini ZEISS, trasforma le immagini in risultati di misura precisi.

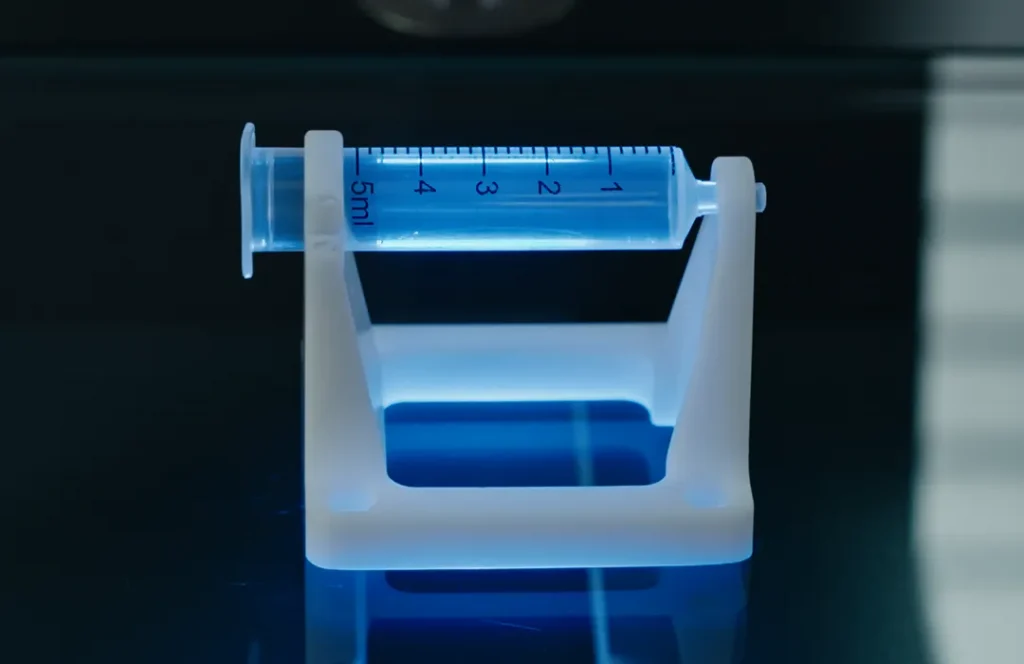

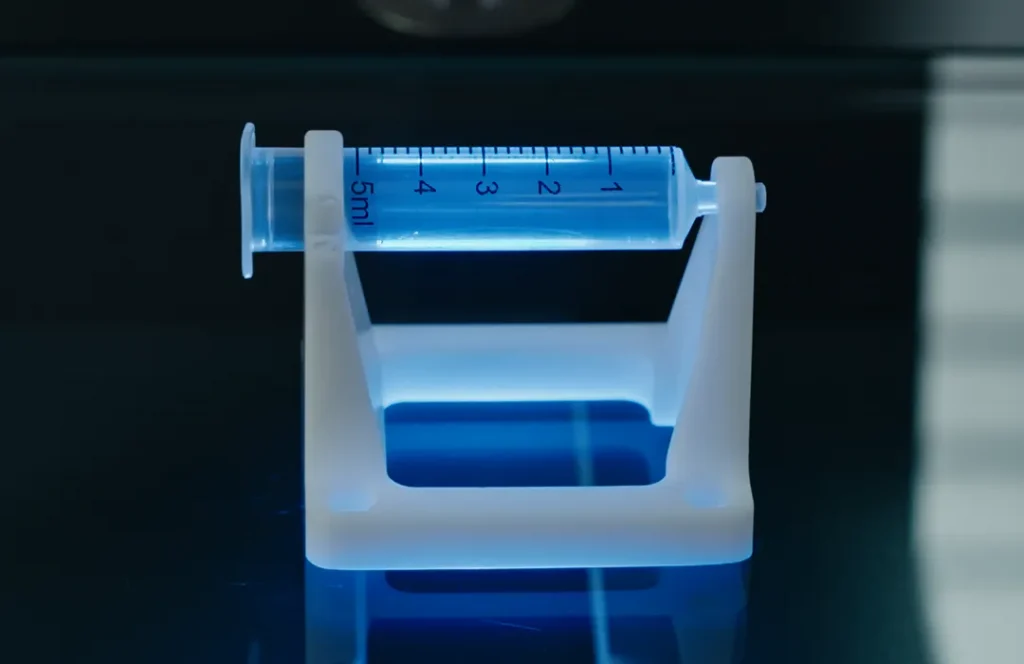

Non sono necessari lunghi preparativi

Con ZEISS O-DETECT e ZEISS INSPECT, i pezzi possono essere ispezionati fin da subito. Praticamente non servono preparativi prima della misura. Basta inserire l’oggetto nel suo stegno, posizionarlo sul vetro e avviare l’ispezione. Nessun compromesso in termini di precisione e rapido inizio della valutazione.

Controllato da ZEISS INSPECT per un uso intuitivo

ZEISS O-DETECT funziona con ZEISS INSPECT. La soluzione software tutto in uno centrata sull’utente è lo standard affermato nella metrologia 3D. Approfittate di funzioni intuitive, come la pianificazione del percorso senza collisioni, la selezione automatica delle strategie di misura e la cella di misura virtuale (VMR) quale elemento centrale per il controllo e la pianificazione delle misure.

Caratteristiche

Illuminazione che fa la differenza

Grazie alle diverse opzioni di illuminazione, questa soluzione si adatta perfettamente alle vostre attività di ispezione. A seconda della superficie del pezzo, diverse luci illuminano il pezzo dall’alto. In questo modo anche le parti lucide o riflettenti possono essere misurate utilizzando la sorgente di luce diffusa. Volete controllare i profili di un oggetto? La retroilluminazione dal basso migliora la qualità dei bordi, per un’ispezione ottica ancora più precisa.

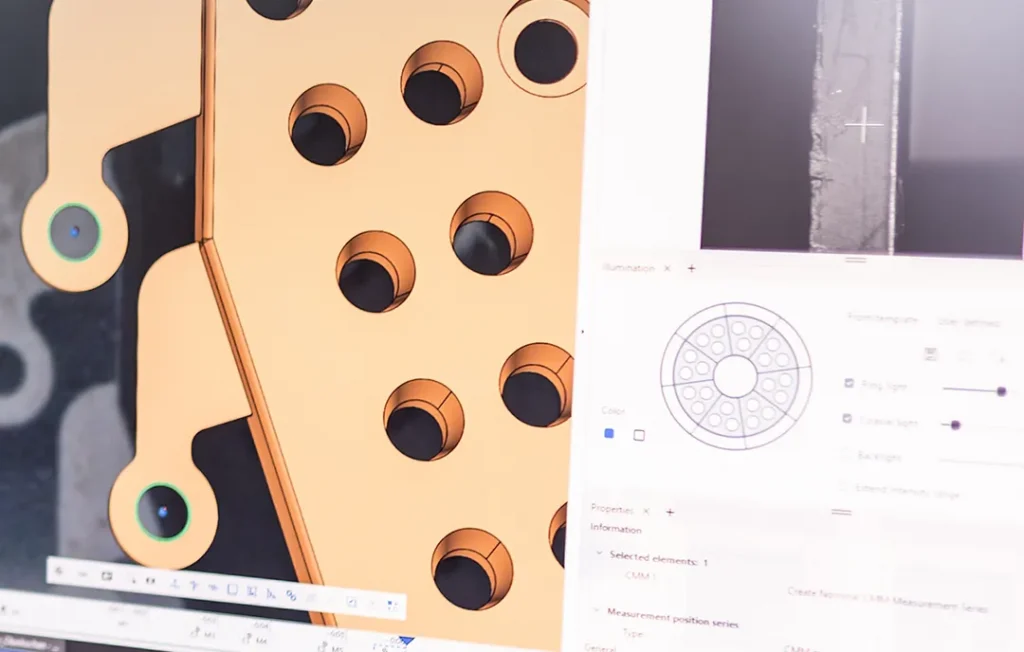

Programmazione di pezzi guidata

Per garantire risultati di misura accurati, la strada da seguire è la programmazione dei pezzi. Lasciatevi guidare nella programmazione del pezzo dal software ZEISS INSPECT. Il vantaggio: piani di misura rapidi e ripetibili per ispezioni in serie con massima qualità dei dati.

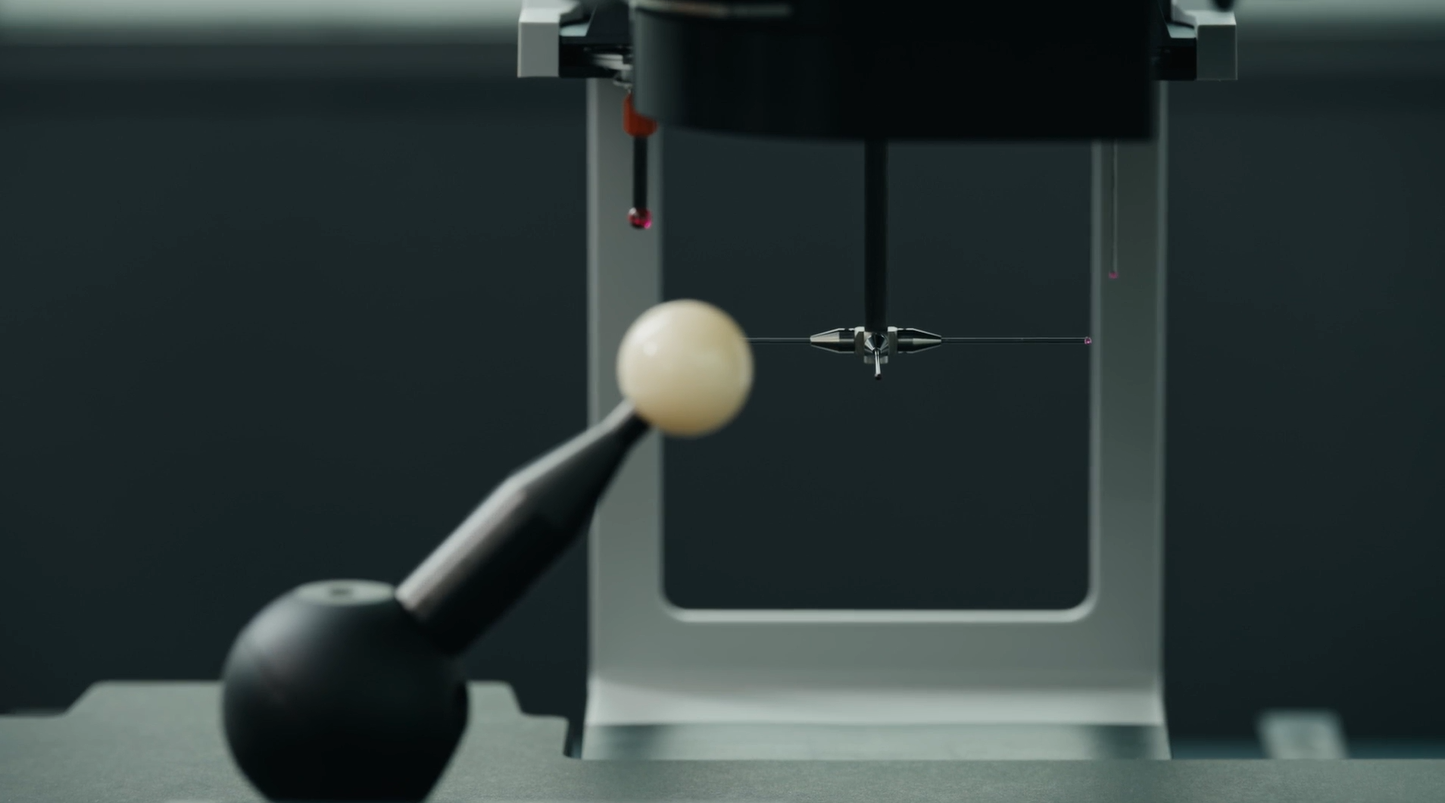

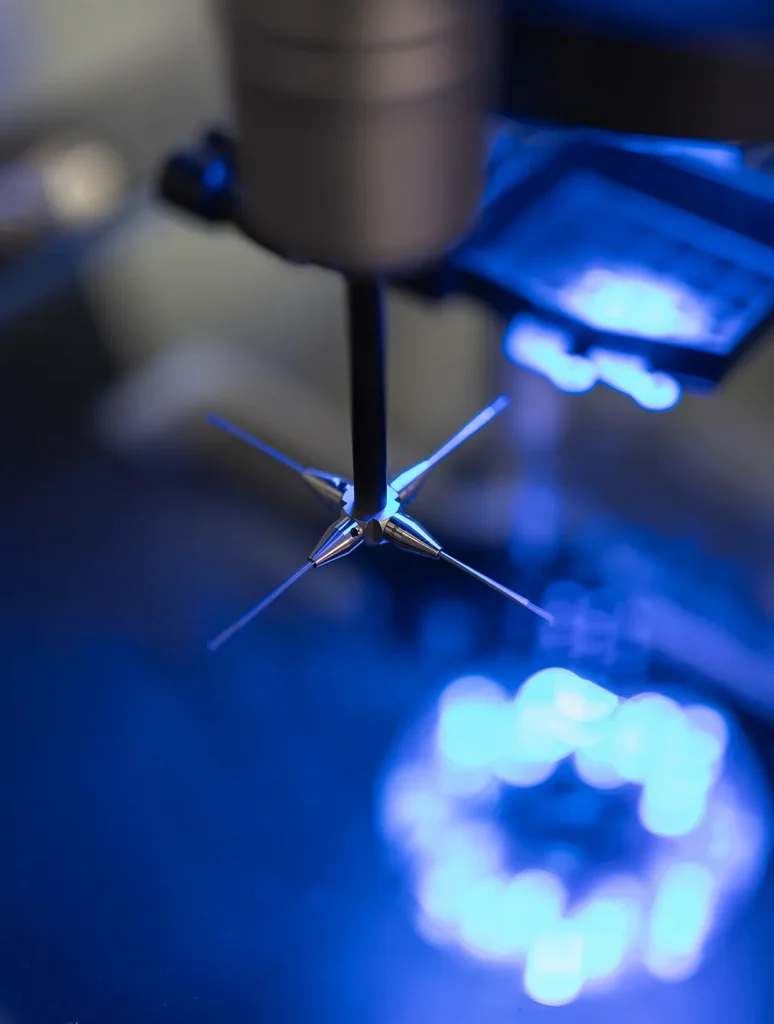

Stili per misurazioni al volo

A volte la misurazione ottica non è sufficiente. Per le aree d’interesse difficili da raggiungere, ZEISS O-DETECT con ZEISS INSPECT offre una semplice estensione della misurazione a contatto. Il sistema a stilo passivo ZEISS XDT è ideato per misure a contatto precise, grazie al comportamento di tastatura stabile durante l’ispezione dei pezzi.

Risultati di misura di alta precisione

Con ZEISS O-DETECT con ZEISS INSPECT non dubiterete mai più dei vostri risultati di misura. Calibrato in base a MPE E(3D) secondo ISO 10360, fornisce dati 2D e 3D affidabili e confrontabili.

Accessori

Casi d’uso illimitati

O-DETECT con ZEISS INSPECT è la scelta ideale per ispezionare parti piccole e piatte, nonché superfici luminose o scure. Grazie alla concezione intelligente dell’illuminazione e all’opzione di misurazione a contatto, è adatto per un’ampia gamma di applicazioni e settori.

Vasta gamma di applicazioni

Settori industriali

- Medico/farmaceutico

- Automotive

- Elettronica

- Aerospaziale

- Plastiche

- Lavorazione di acciai

Materiali

- Metalli

- Ceramiche

- Compositi

- Plastiche e gomma

- Vetro

Processi

- Stampaggio e taglio

- Fusione e fresatura

- Incisione

- Estrusione e sinterizzazione

Dati tecnici

ZEISS INSPECT

in 3D: 2.4 μm + L /150 μm

in 3D: 2.4 μm + L /150 μm

Volete scoprire di più?

Mettetevi in contatto con il vostro partner #HandsOnMetrology locale.

Scopri di più

i

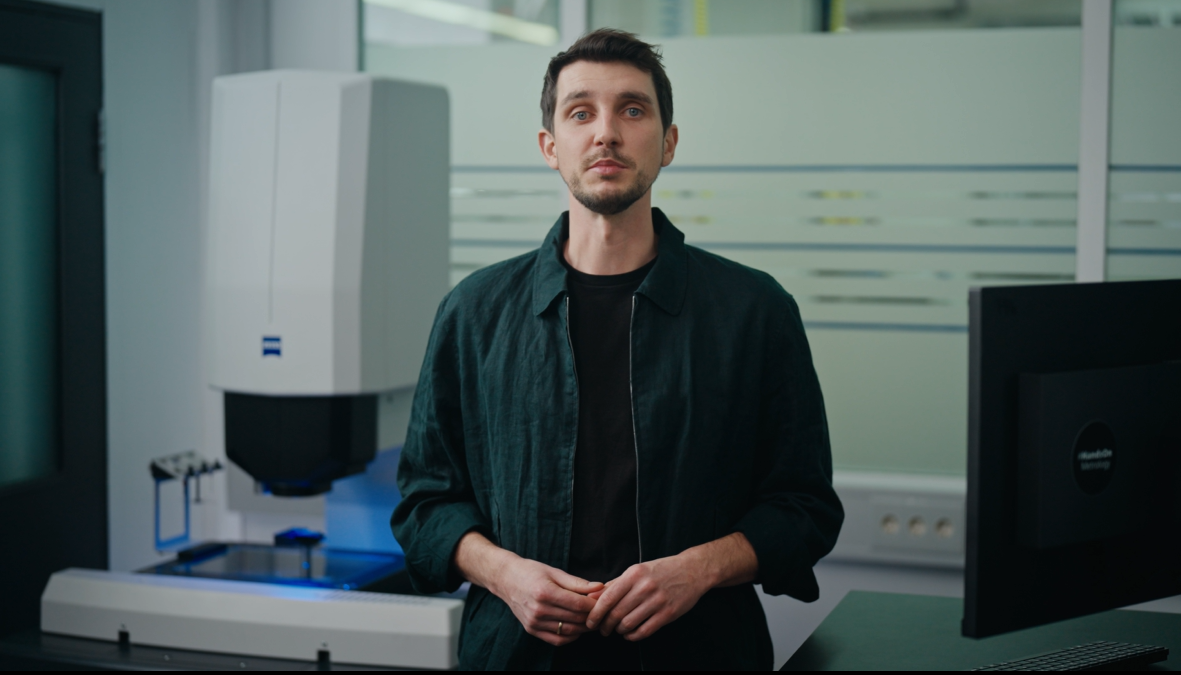

Please select the topic you seek more information aboutO-DETECT with ZEISS INSPECT: The basics of vision measurement technology

This video covers the basics of vision measurement technology. Our VMM expert Timo gives an overview of the optical and tactile inspections possibilities and the features of our VMM ZEISS O-DETECT with ZEISS INSEPCT.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

O-DETECT with ZEISS INSPECT: The setup

You just got your VMM and directly want to start with your optical or tactile inspection task? Watch this Getting Started to learn how to set up ZEISS O-DETECT with ZEISS INSPECT for fast and accurate tactile inspections.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

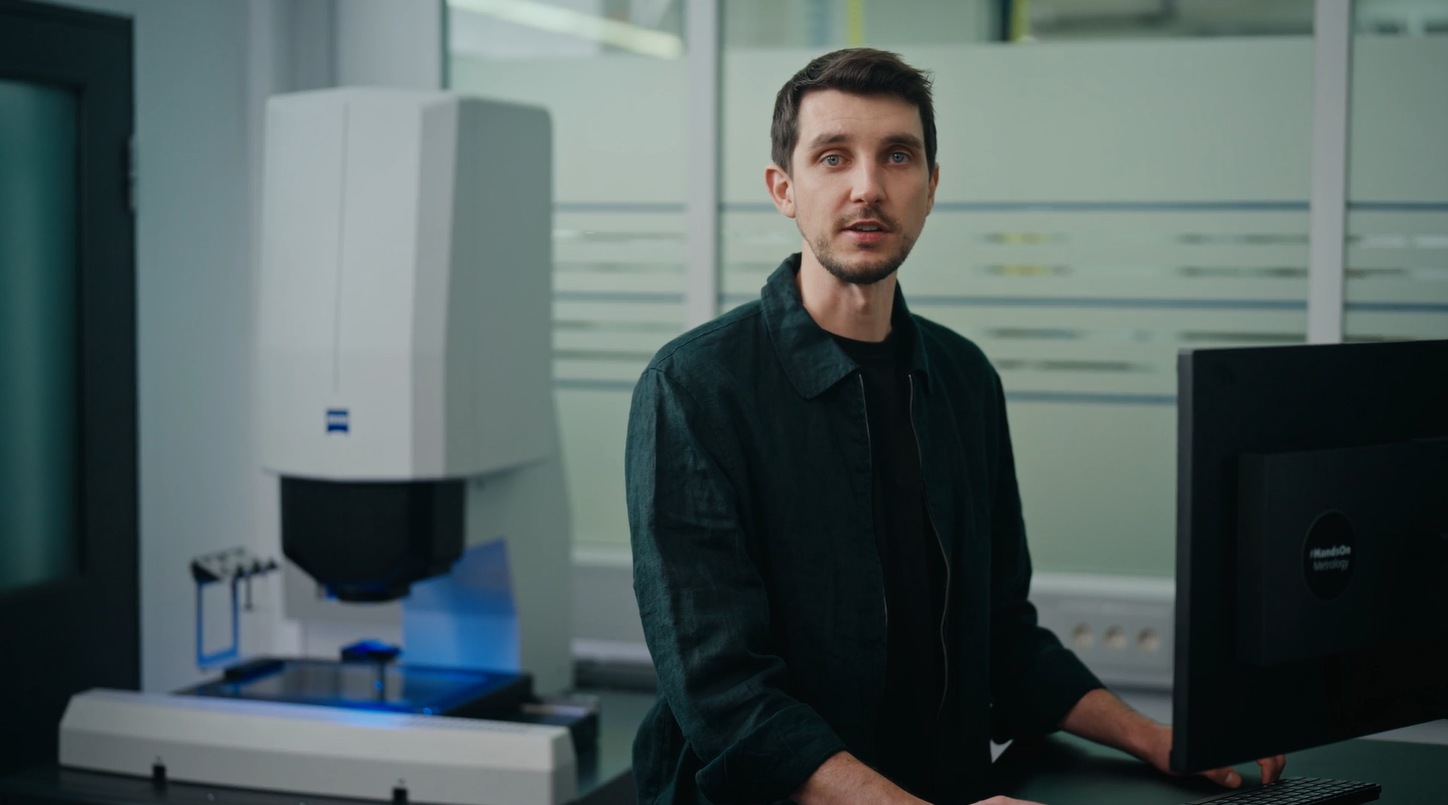

O-DETECT with ZEISS INSPECT: Introduction to ZEISS INSPECT

ZEISS INSPECT software offers easy operation of your VMM and simplifies the evaluation of optical and tactile measurement data of your VMM. In this Getting Started, Timo gives insights into our software solution for VMMs and highlights important features, like the VMR.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

O-DETECT with ZEISS INSPECT: Aligning optical and tactile sensors

Unlock the full potential of your Vision Measuring Machine by preparing measurements the right way. Let Timo show you how to align the optical and tactile sensor of your VMM to receive accurate measurement data every time.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

O-DETECT with ZEISS INSPECT: Performing simple measurements

Start your first multi-sensory inspection with ZEISS O-DETECT with ZEISS INSPECT by following a few simple steps. Watch this Getting Started to learn more about multi-sensory measurements with a VMM and recieve your precise optical and tactile data in a matter of moments.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

O-DETECT with ZEISS INSPECT: Measuring complex parts

VMMs are made for inspection in various industries and thus often need to capture complex geometries and small features at the highest accuracy possible. In this video you will learn the basics of complex parts measurements, including tips to simplify part programming.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

O-DETECT with ZEISS INSPECT: Reports for series measurements

Reports are what give meaning to the inspection data of your VMM. With ZEISS INSPECT software for VMMs you have all features at hand to level up data evaluation, even for series measurements. Let Timo show you how it’s done in our all-in-one software.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com