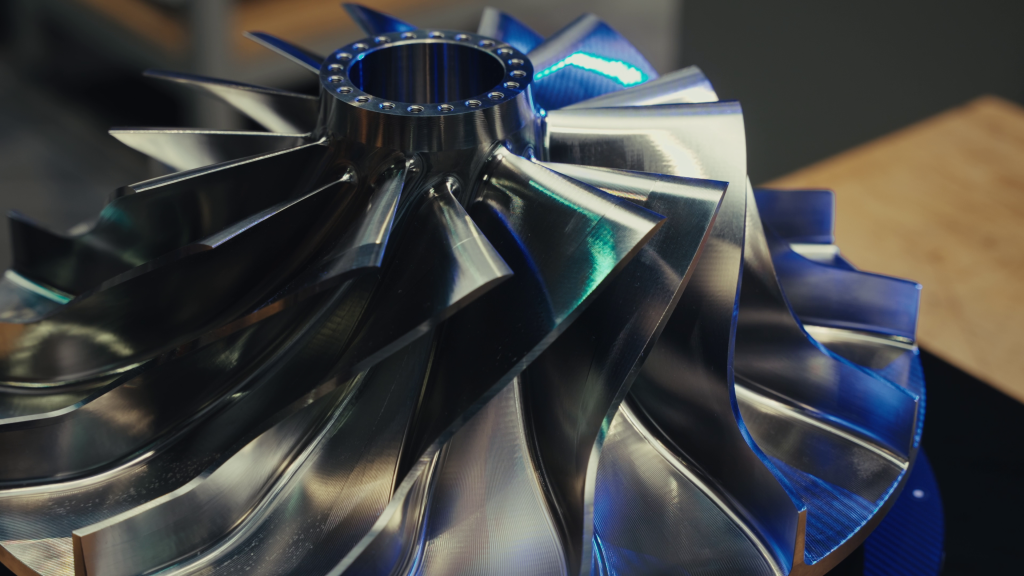

Andreas Bruns Zerspanungstechnik is a traditional contract manufacturer with 14 employees based in Germany. What started in a small garage with just two machines, quickly grew into an established company in a modern manufacturing hall. The company specializes in turning, milling, wire cutting, and testing, and delivers precision-engineered parts for a wide range of industries. A special focus lies on aerospace manufacturing because of the highly complex components and materials.

Navigating aerospace challenges

The aerospace industry is renowned for its strict requirements. Components must meet the highest accuracy levels to ensure safety and performance. Andreas Bruns Zerspanungstechnik has made it their mission to address these challenges head-on, ensuring full functionality and reliability of every part they manufacture.

The role of 3D scanning technology

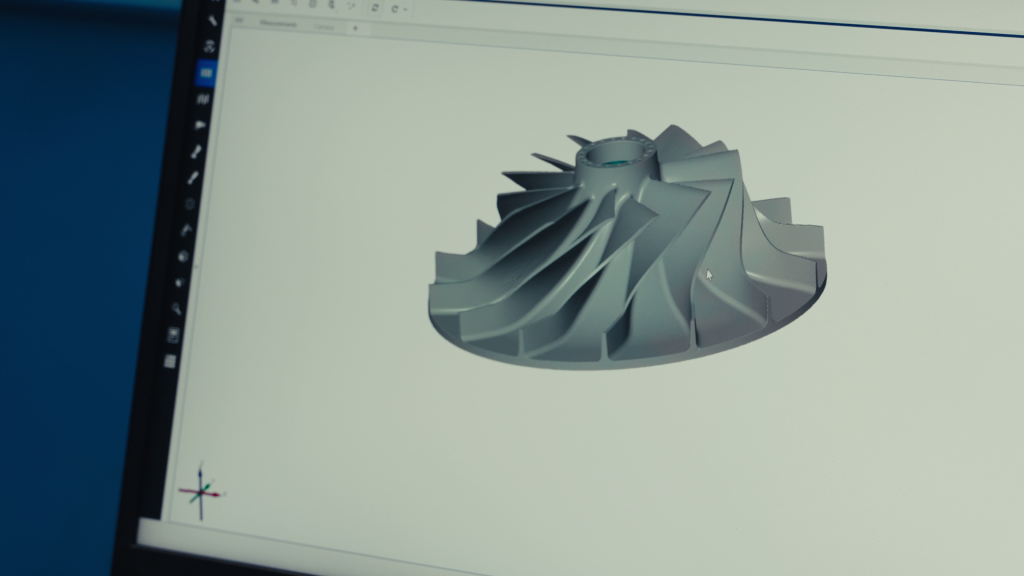

To meet the high standards of aerospace manufacturing, Andreas Bruns Zerspanungstechnik has integrated 3D scanning technology into its workflow. This approach allows them to optimize production processes based on the scanning results and therefore maintain consistent quality of their produced parts, even for the strict specifications required in aviation.

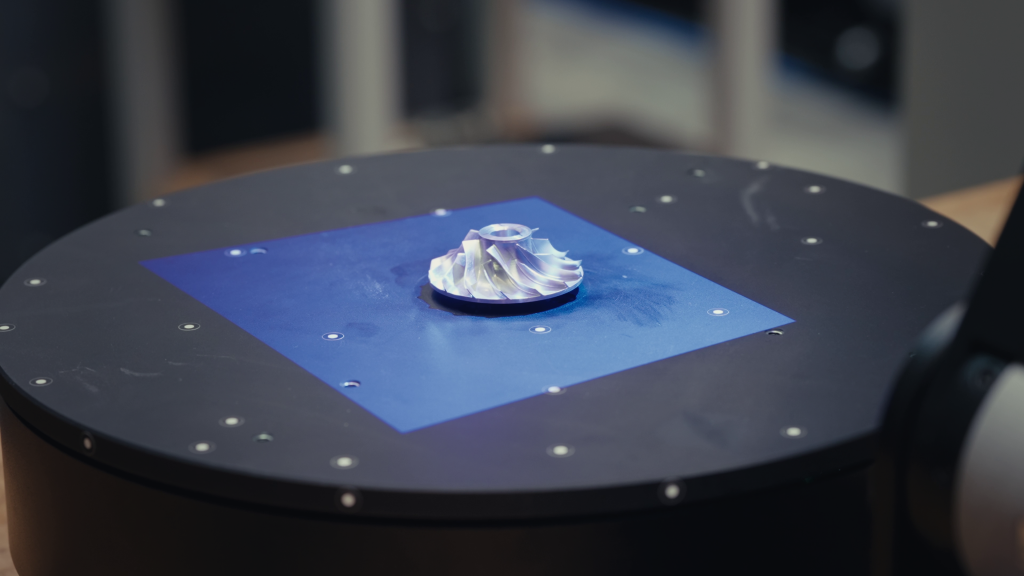

Quality control with ZEISS ScanPort

Central to their quality control is the ZEISS ScanPort equipped with the ATOS Q sensor. This solution offers several advantages:

Time efficiency

Reducing the time needed for measurements and improving production workflows.

Versatility

Different measurement volumes ensure parts of all sizes are scanned with highest accuracy.

Ease of Use

User-friendly operation of the system and the software with clear step-by-step guidance.

3D scanning with ZEISS ScanPort and ATOS Q has become an important tool for the team, enabling them to save time, refine production processes, and deliver precision-engineered products.

Watch the full Maker Portrait

Aerospace manufacturing is a field where precision is non-negotiable. With the integration of 3D scanning technology and ZEISS ScanPort, Andreas Bruns Zerspanungstechnik is not only meeting the industry’s rigorous demands but also shows the company’s commitment to modern and innovative technology. In the future, they want to continue to focus on automation, digital processes and sustainable production. Want to hear more about Andreas Bruns Zerspanungstechnik? Watch the full video:

Andreas Bruns Zerspanungstechnik: Manufacturing of complex parts for aerospace

Discover the story of Andreas Bruns Zerspanungstechnik, a traditional contract manufacturer specializing in precision engineering for industries like aerospace. By utilizing ZEISS ScanPort with ATOS Q, they optimize their production and quality control and deliver highly accurate parts to their customers. Would you like to find out more about Andreas Bruns Zerspanungstechnik? Visit https://andreas-bruns.de/

ScanPort

ATOS Q

3D scanners for 3D printers

3D scanners and 3D printers are widely used across industries for product development, quality assurance, and reverse engineering. The overlap between these applications creates the potential for a powerful combination of both technologies. As a leading manufacturer in metrology, ZEISS offers high-precision 3D scanners for 3D printers that deliver exceptional accuracy and detailed surface capture, making them ideal for seamless integration of 3D scanning and 3D printing in industrial workflows.

3D scanners for small objects

Small objects place unique demands on the scanner, camera, and software used during 3D scanning. To capture even the finest details with precision, systems must offer high accuracy and resolution capable of reproducing complex surfaces correctly. Simple systems, such as depth cameras, often fail to deliver sufficient scanning results when true precision is required.

In this guide, you’ll learn which solutions are best suited for the precise digitization of fine structures, what to consider when choosing a 3D scanner for small objects, and which ZEISS small 3D scanners have proven their reliability in real-world applications.

3D scanners for large objects: Precise measurements at full scale

Large objects such as cars, industrial equipment, or complex mechanical components are often difficult to digitize with conventional scanners. A 3D scanner for large objects needs exceptional range, the ability to capture large scan volumes, and the highest accuracy and resolution. Today’s large 3D scanners combine powerful technology, handheld flexibility, and fast data processing algorithms to produce highly detailed 3D scans of big objects.

In this guide, you’ll discover what requirements a 3D scanner for large objects must meet, which applications benefit most from this scanning technology, and which 3D scanners and software solutions ZEISS offers for large-scale objects.