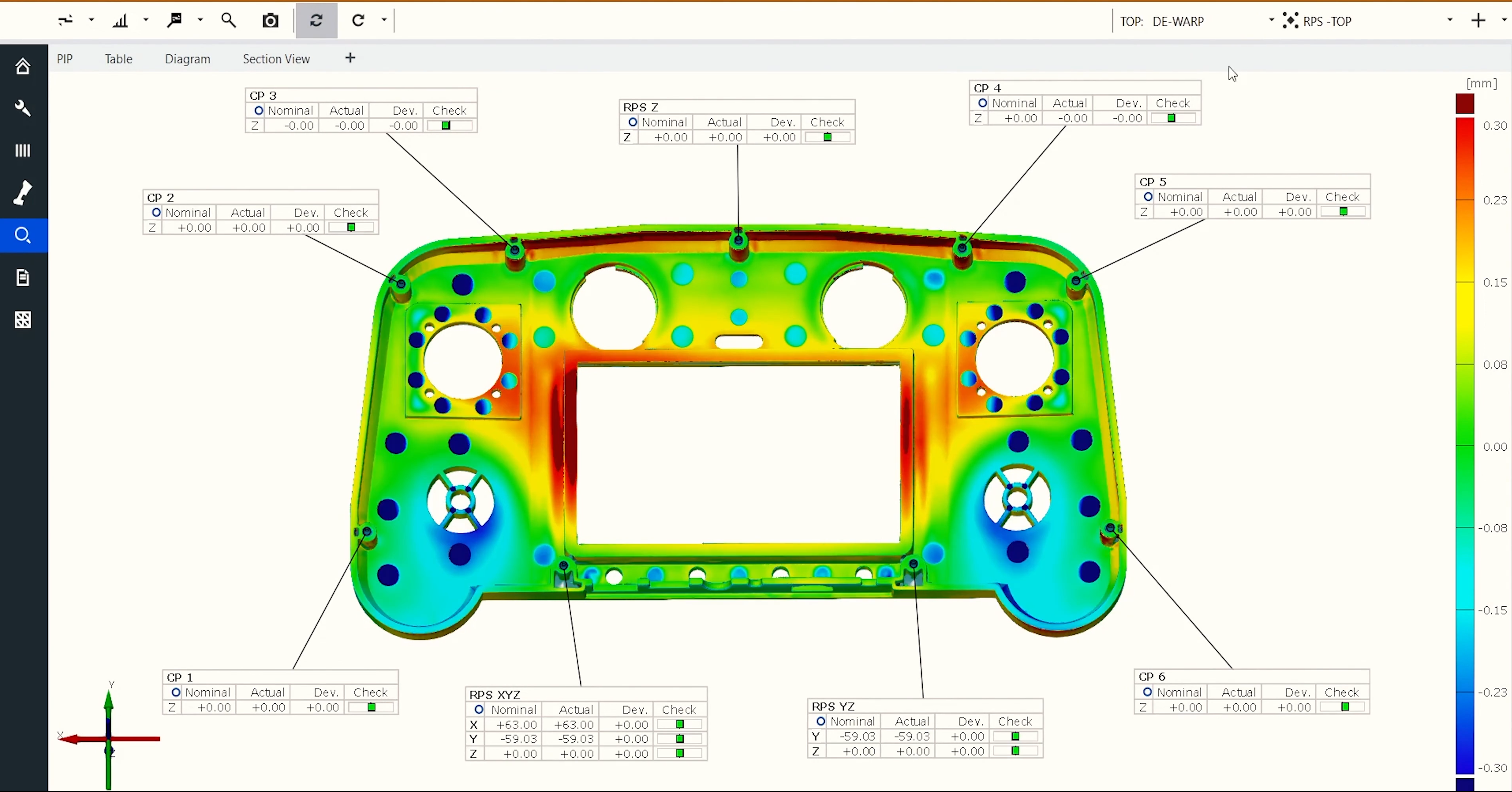

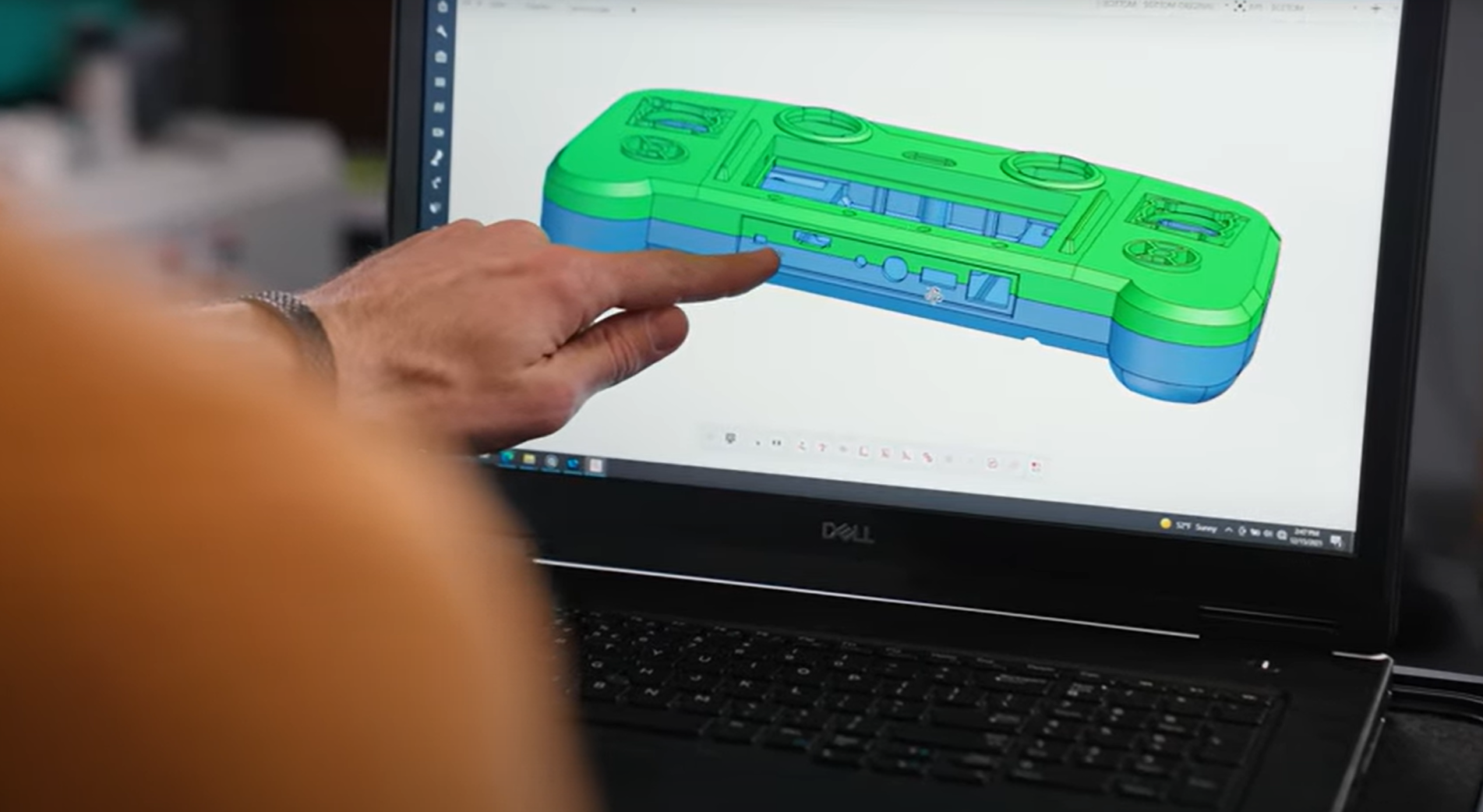

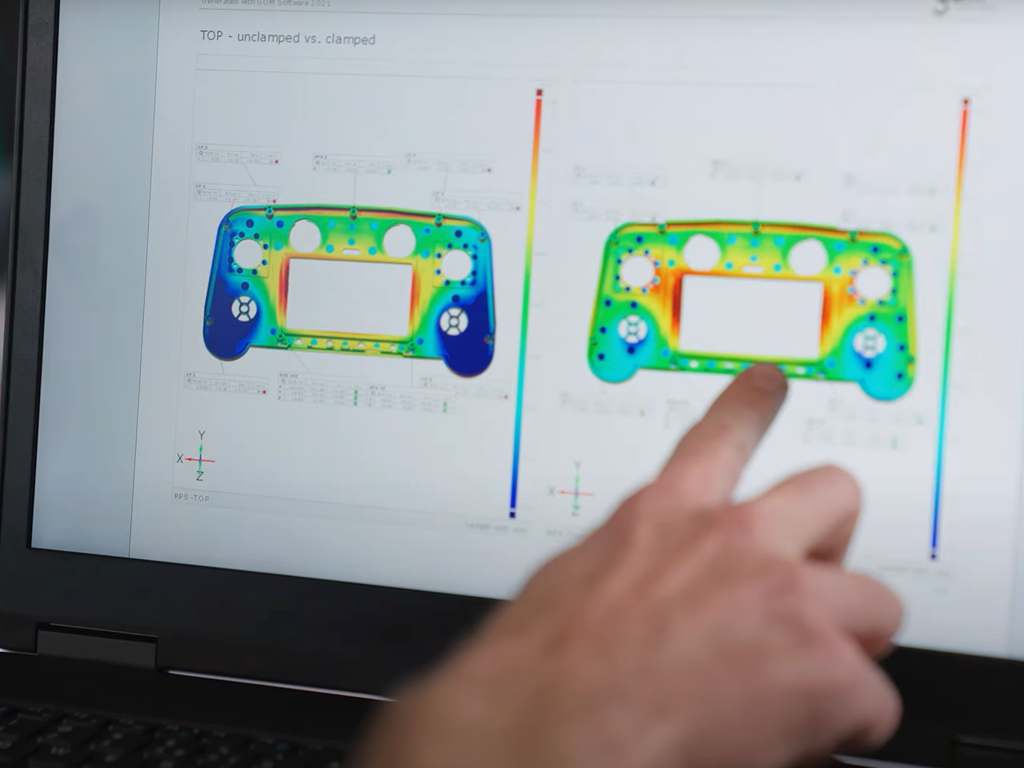

The De-Warp software App can compensate warpage and shrinkage of plastic parts virtually. With one single click you can put scanned plastic parts into a virtually assembled stage without any mechanical fixtures. With this feature, you can also very easily switch between the two states unclamped and clamped to compare their dimension.

De-Warp: a new level of...

Quality Control

Be able to switch between two results (unclamped/clamped) with only one complete measurement and compare them to the CAD model. A correct evaluation of your part was never easier!

Functionality

De-Warp virtually assembles your part, therefore you don’t need an actual fixture. It allows you to check whether the part dimensions are within tolerance in the subsequent assembly.

Time Saving

Getting all results you need with only one measurement, De-Warp will save you a lot of time and money. And nerves.

De-Warp functions: How it works

More powerful ZEISS INSPECT (full version)

Features

ZEISS INSPECT

(full version)

(full version)

Edit Projects

CAD Import

Mesh Editing

Reporting

3D Inspection

How to Eliminate the Warpage of Plastic Parts

Play Video

Do you have further questions on De-Warp?

Don’t hesitate to contact us. We’re more than happy to help.

Discover our newest video sessions

Follow us

Sessions

Solutions

Digital Events

Subscribe to our newsletter

- Privacy Policy

- Imprint

- ©2023. All Rights Reserved

Menu