Requirements for 3D scanners for large objects

To reliably digitize large objects, a 3D scanner needs more than just advanced technology: it must also integrate seamlessly into existing workflows. The following factors are key to achieving accurate, fast, and practical scanning results at full scale:

Scan volume & measuring field

A wide measuring range is essential when scanning large objects. Higher resolution usually reduces the measuring field but increases the level of detail captured in that area.

Accuracy & resolution over distance

Even at greater distances from the object, the 3D scanner must ensure high accuracy and resolution.

Surface & environment

Dark or reflective surfaces, as well as changing lighting conditions, pose specific challenges. Modern systems compensate for these effects by using intelligent algorithms.

Scanning speed & workflow

When digitizing big objects with a 3D scanner, high scanning speed and efficient data processing are crucial to maintain a productive workflow.

Software integration

Powerful software solutions are required to analyze large point clouds and connect them seamlessly with CAD or CAE systems.

Device selection

Depending on the application, different scanner types are used. Modern handheld 3D scanners for large objects can now handle many tasks that were once reserved for stationary systems.

A powerful 3D scanner for large objects combines range, resolution, and scanning speed with intelligent software integration, meeting the highest standards of precision and efficiency even under challenging conditions.

Applications of 3D scanners for large objects

3D scanners for large objects are used wherever complex components or entire systems need to be captured, inspected, or reconstructed with high precision. They demonstrate their full strengths particularly in the following applications:

Quality assurance & production control

In industries such as automotive, aerospace, and mechanical engineering, 3D scanners for large objects enable precise nominal-to-actual comparisons. Deviations can be detected early, allowing targeted optimization of manufacturing processes.

When no CAD data is available or replacement parts need to be reproduced, large industrial components can be captured and digitally reconstructed through 3D scanning, an efficient solution for maintenance and remanufacturing.

Design validation & prototyping

Even large-scale prototypes can be quickly captured and analyzed using handheld 3D scanners for large objects such as T-SCAN hawk 2. This accelerates the development process and helps optimize the CAD model based on real-world data.

ZEISS 3D scanners for large objects

Even when dealing with large-volume components, ZEISS focuses on maximum accuracy, efficiency, and ease of use. To digitize big objects, ZEISS offers a powerful 3D scanner specifically designed for flexible operation on large-scale structures.

T-SCAN hawk 2

ZEISS T-SCAN hawk 2 is a versatile handheld 3D scanner for large objects designed for mobile measurement applications. With its compact design and intuitive operation, T-SCAN hawk 2 is ideal for on-site use. Even in large-scale scanning scenarios or at greater distances from the object, this 3D laser scanner captures fine details with outstanding accuracy. Typical applications include quality assurance, reverse engineering, maintenance, and prototyping.

Analysis and reverse engineering with ZEISS software solutions

When working with large objects, the process doesn’t end with scanning. Equally important is the precise and efficient processing of the captured 3D data. ZEISS provides two powerful software solutions specifically tailored to industrial requirements. Whether for analysis, inspection reports, or integration into CAD systems, ZEISS INSPECT and ZEISS REVERSE ENGINEERING enable seamless incorporation of large-scale point clouds into existing manufacturing and development workflows. Common exchange formats, such as STL, are also processed reliably.

ZEISS INSPECT

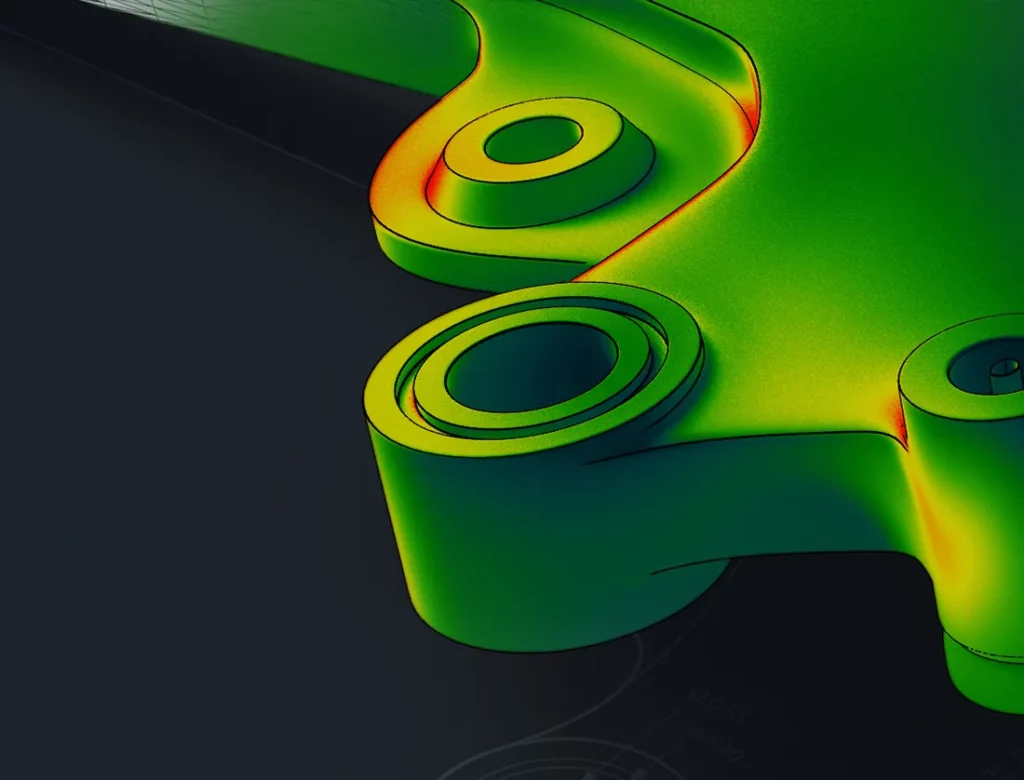

ZEISS INSPECT is a powerful solution for analyzing large 3D scan data. The software transforms extensive point clouds into meaningful analyses and supports visual evaluation of surfaces, dimensional deviations, and tolerances. With integrated tools for inspection reports, dimensional analysis, and digital documentation, ZEISS INSPECT provides everything needed for comprehensive quality assurance. Industrial data formats are processed reliably, and the 3D software is fully compatible with all optical ZEISS scanners.

ZEISS REVERSE ENGINEERING

ZEISS REVERSE ENGINEERING provides precise surface reconstruction, even for complex or freeform structures, ideal when no digital design data is available. The software converts large point clouds or polygon meshes into CAD-ready models, recreating even intricate geometries in full detail. It is particularly suited for the reconstruction of mechanical parts, automotive components, or industrial equipment. Exporting to common CAD formats such as STEP or STL is seamless, and direct integration with ZEISS INSPECT is also available. The software is fully compatible with optical 3D scanners for large objects, including T-SCAN hawk 2.