The work at Boondock Van Co.

Boondock Van Co. is the place to go when it comes to custom van conversions – optimized for the individual needs of each customer. The luxurious vans make mobile travelling more aesthetically pleasing and offer maximum comfort. Their work is based on 3 pillars – guaranteeing perfect solutions every time:

High-quality & customization

Every customer’s imagination of the perfect travel experience is different – so are the customized vans of the company. However, the high level of quality is non-negotiable – regardless of the design.

Longevity

Endless travelling fun included. Durability and longevity are always in the company’s mind to ensure adventures without time limits and maximum confidence.

Our passion for the outdoors and firsthand van life experience ensures that each van is built with integrity, hospitality, and environmental consciousness, resulting in a personalized home that exceeds our client's expectations.

Boondock Van Co.

Customizing vehicles with 3D scan data

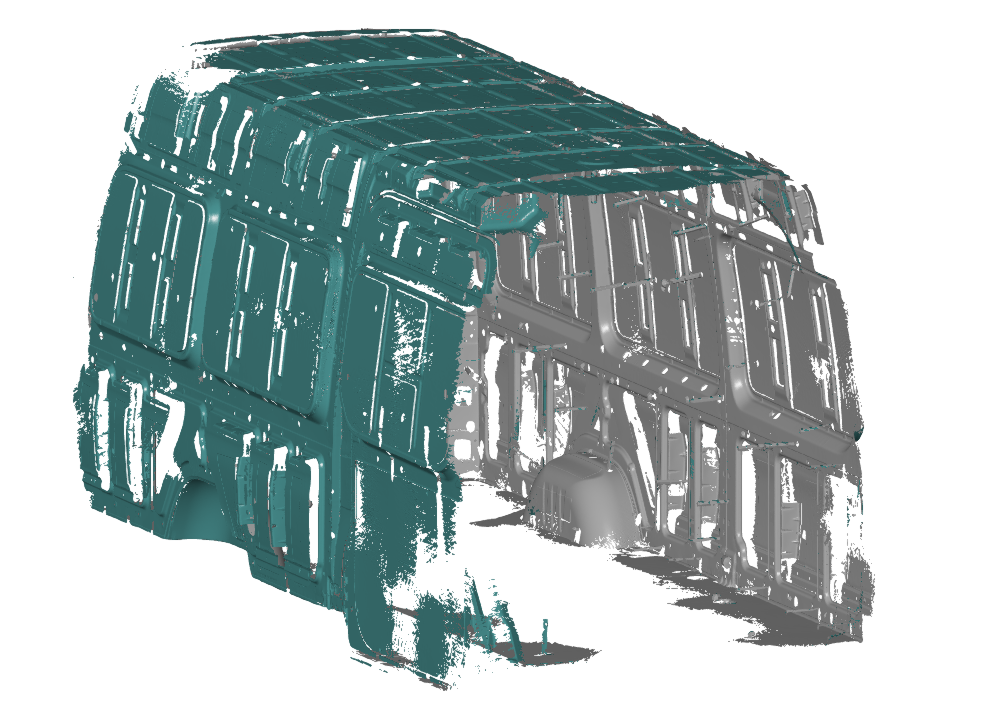

For their latest project, Boondock wanted to upgrade a Mercedes sprinter van. The main task was to completely scan the interior of the vehicle and thus generate necessary data for retrofitting.

It was particularly relevant to quickly digitize the large areas in order to be able to work efficiently on the redesign. For this purpose, magnetic polyhedrons and bars were used, which could be easily attached to the interior of the van due to their magnetic properties. These are equipped with a large number of reference markers and later enable perfect referencing of the data to each other in the software. The manual application of individual reference points was eliminated and sped up the scanning process.

The scanning solution of choice was the ZEISS T- SCAN hawk 2. The hand-held system performed particularly well in the van and showed its strengths in the mobile application. It delivered data directly on site. The 3D scan solution was also able to stabilize hand movements and thus generate even more accurate data. The large measuring volume as well as the built-in satellite mode of the scanner additionally supported the task. Scanning objects up to multiple meters was possible. Classic built-in photogrammetry with coded markers is no longer needed without compromising accuracy.

The inspection software does its magic

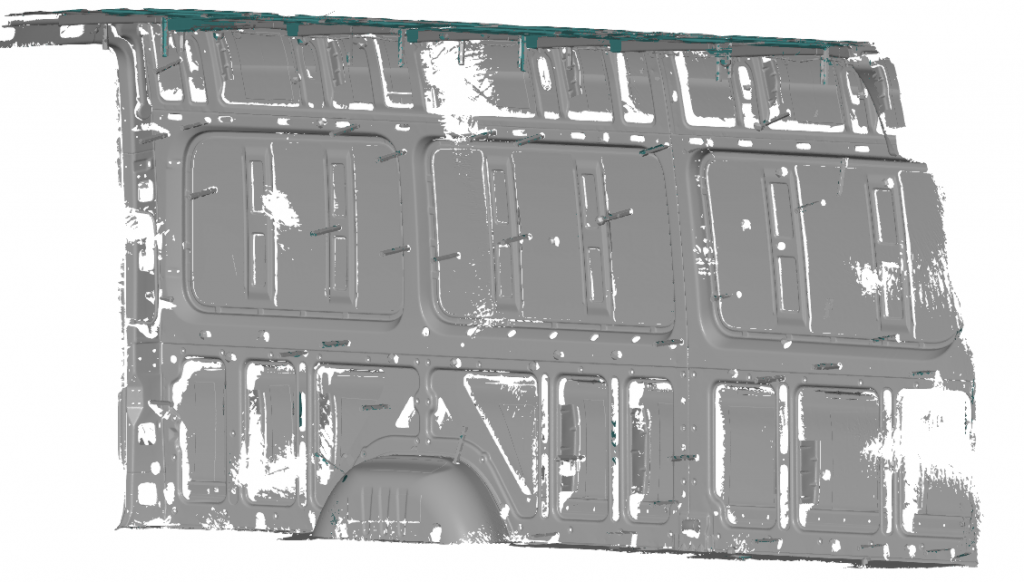

With the aim of generating the complete interior of the van as a mesh, the 3D scan data was bundled in the ZEISS Quality Suite inspection software. For the scan of the large surfaces, the remote workflow proved to be a simplification. The collection of all necessary dimensions was thus intuitively possible without having to operate the laptop separately. Large-area meshes were generated quickly and can provide valuable information for retrofitting.

Professional retrofitting at its best

The result? See for yourself!

A modern, bright and multifunctional camper van for a comfortable travel experience – based on 3D scan data.