Qualità inizia con la Q

ATOS Q: lo scanner 3D industriale ad alte prestazioni

Una soluzione di scansione 3D per compiti complessi di misurazione e ispezione

Affidabile, versatile e compatto

Mobile, versatile e preciso: ATOS Q è pronto per l’impiego nel vostro reparto di produzione. Pensato come scanner 3D flessibile per compiti complessi di misurazione e ispezione, soddisfa elevati requisiti metrologici per diversi settori industriali. In combinazione con ZEISS INSPECT, è un sistema di misurazione ottica 3D rapido, compatto e facile da usare, con vero DNA ATOS.

Progettato per l’uso industriale

Dotato di tecnologia all’avanguardia

Risultati rapidi, prestazioni eccellenti

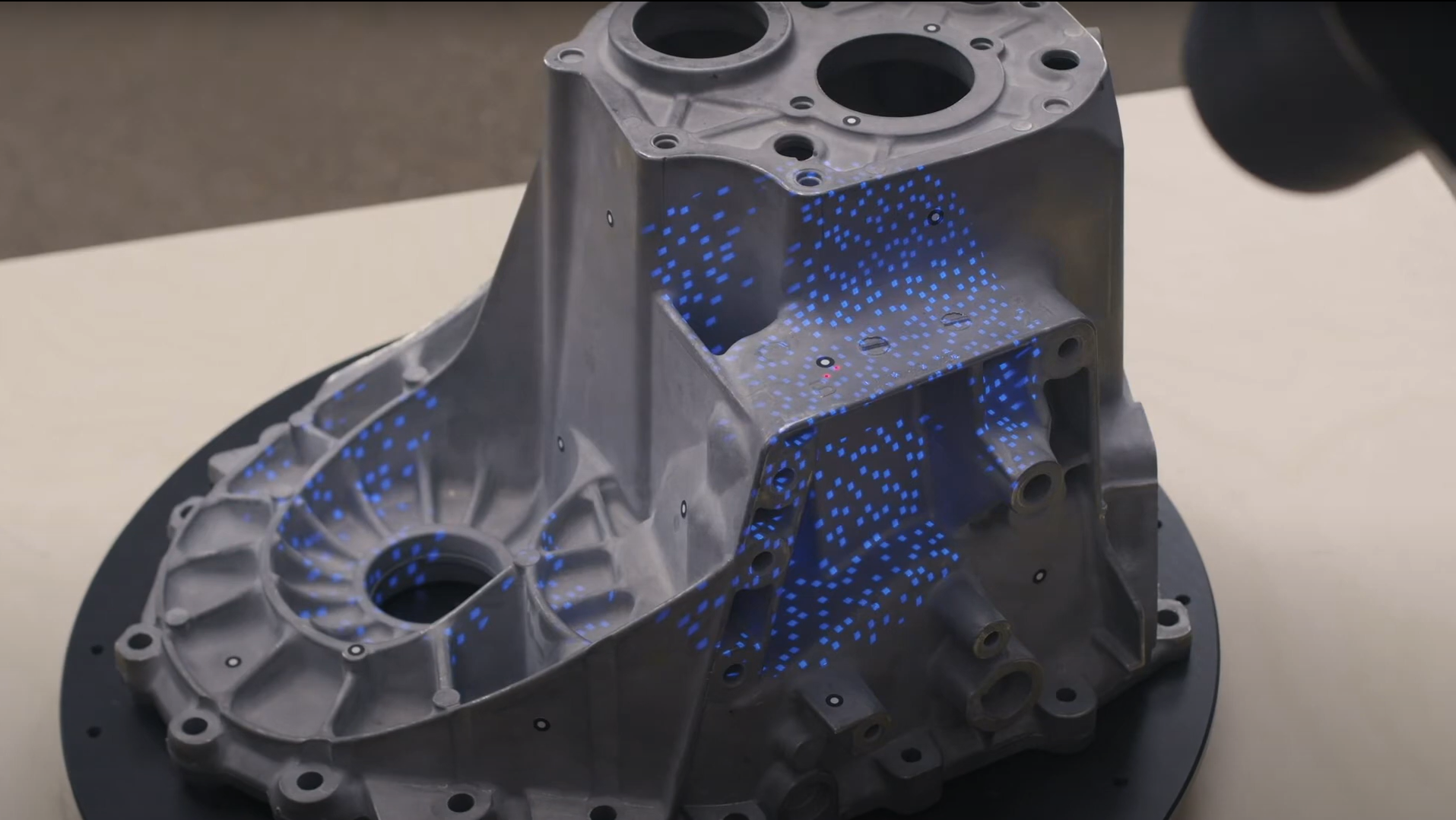

Precisione elevata grazie alla Blue Light Technology

In base al principio delle telecamere stereoscopiche, accurati modelli a frangia vengono proiettati sulla superficie dell’oggetto e acquisiti da due telecamere. La tecnologia di proiezione lavora con luce blu a banda stretta, il che significa che le interferenze luminose presenti nell’ambiente possono essere filtrate durante l’acquisizione dell’immagine.

Estremamente versatile e pronto ad affrontare qualsiasi sfida

Manuale

Grazie al suo peso di soli 4 kg e alla sua struttura compatta, lo scanner 3D ATOS Q può essere spostato facilmente. Montato su un treppiede, è adatto all’utilizzo nella sala metrologica e all’uso mobile nel reparto produzione.

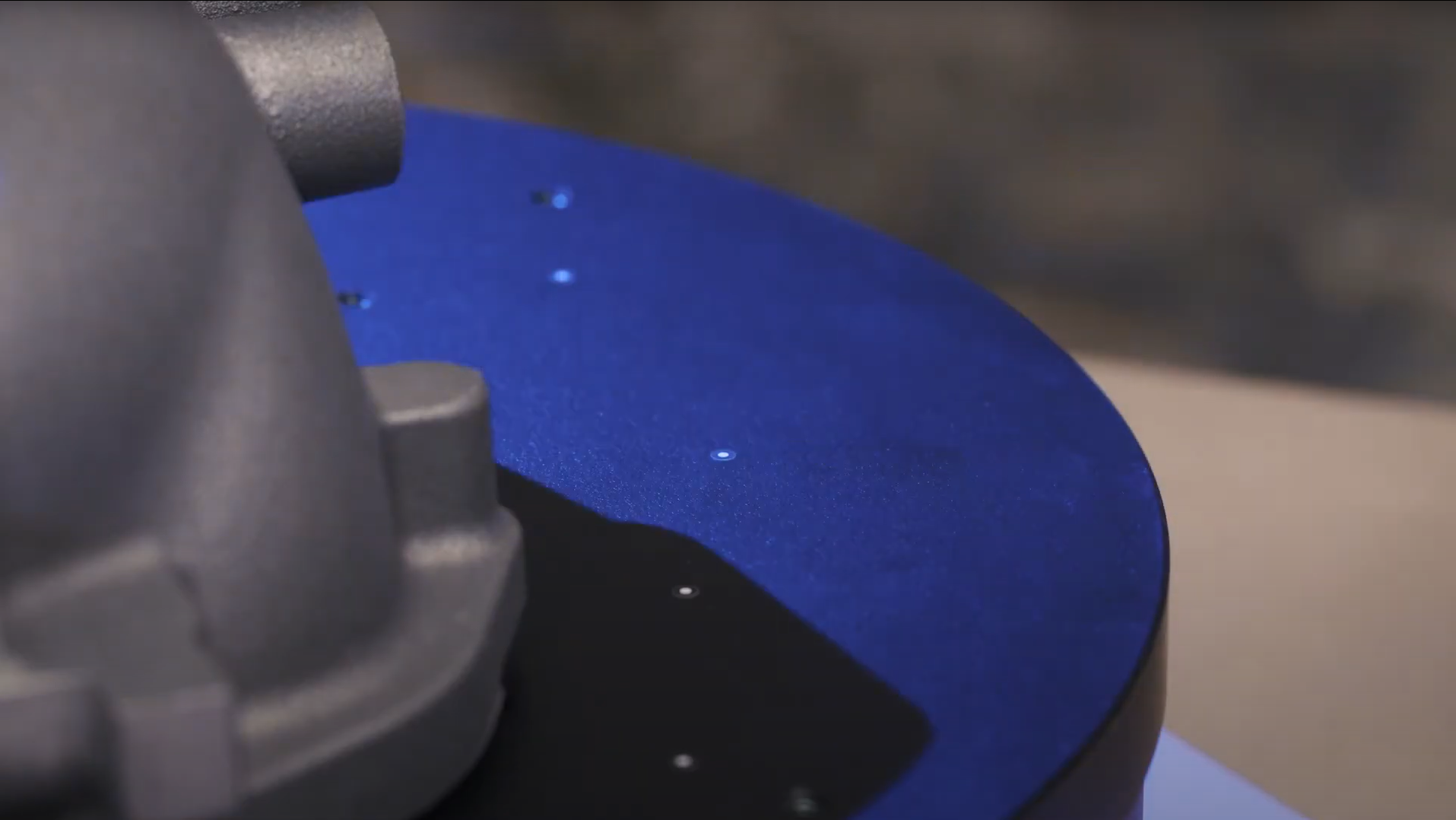

Semiautomatico

In combinazione con un treppiede o uno stativo da tavolo e il tavolo di scansione rotante ROT 350 o un kit di motorizzazione, lo scanner 3D ATOS Q può essere utilizzato anche in modalità semiautomatica.

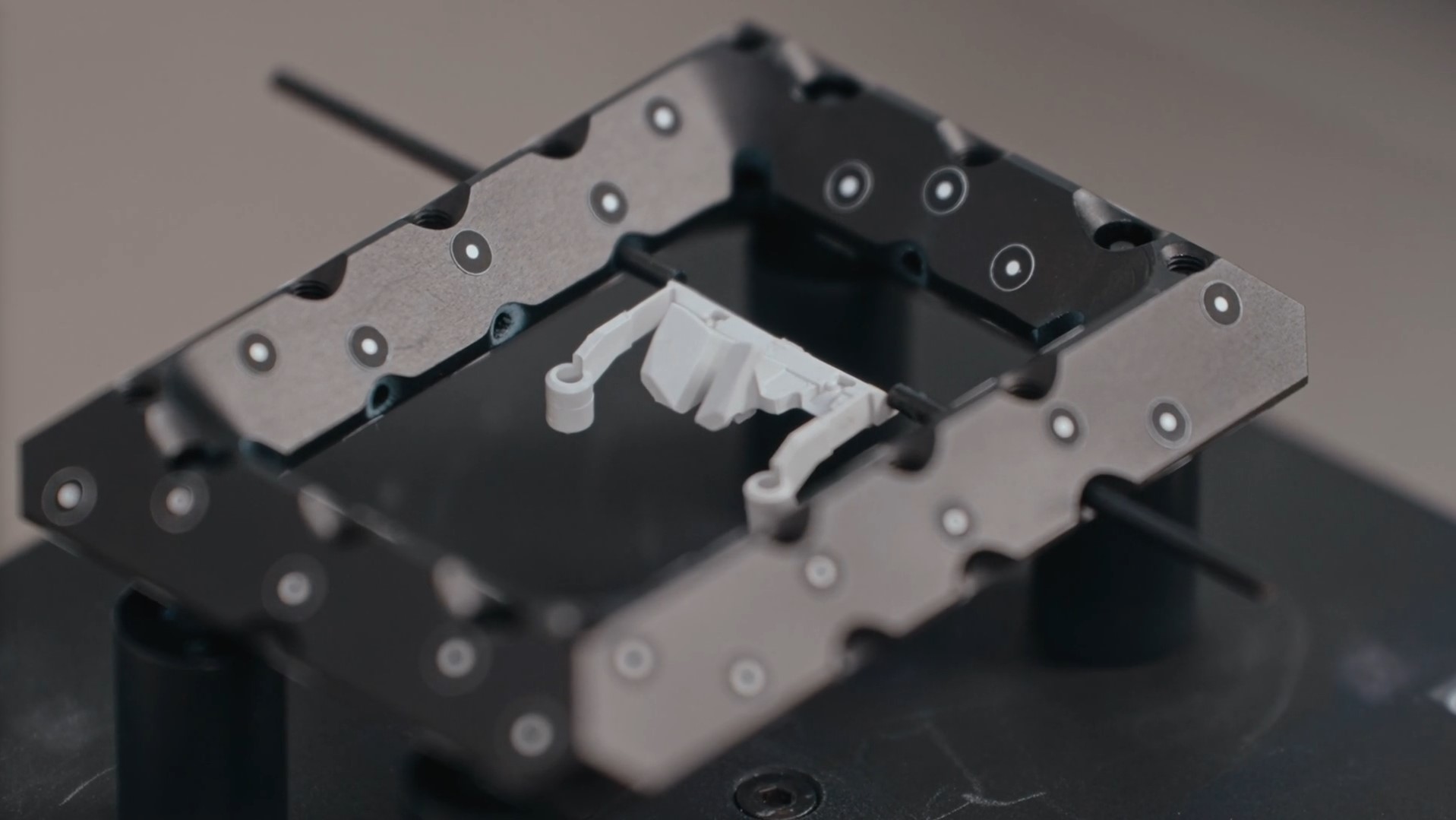

Forgiare la qualità con volumi di misura multipli

Le lenti intercambiabili garantiscono misurazioni ad alta precisione di componenti di piccole e medie dimensioni. Il passaggio dal volume di misura più piccolo a quello più grande è facile dal momento che la posizione della telecamera rimane fissa.

ATOS Q garantisce la qualità

- di componenti prodotti con tecniche di produzione additiva

- di componenti in plastica e stampati a iniezione

- in processi di colata in sabbia, pressofusione e microfusione di precisione a cera persa

- in catene di processo di punzonatura, piegatura, trafilatura, pressatura e formatura

Dati tecnici

Discover ZEISS INSPECT - Pro Line for ATOS Q

Volete scoprire di più?

Mettetevi in contatto con il vostro partner #HandsOnMetrology locale.

Discover more

i

Please select the topic you seek more information aboutHow to save time with ZEISS INSPECT

Let Matt show how quality control becomes more efficient using the full version of ZEISS INSPECT. Whether inspecting one or multiple parts, templates transfer pre-made inspection steps in one click. Trend project function furthermore helps when all parts need to be checked at once – making evaluation fast, easy and intuitive.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to scan small parts using compact 3D scanners

3D scanning of small parts and fine details is often a challenge that can take a lot of time. In this How-to, Matthias shows you how you can take the 3D scanning process to a new level with the help of ATOS Q, GOM Scan 1 and the Motorization Kit.

Do you have any question on our 3D scanners? Contact us via support@HandsOnMetrology.com

How to 3D scan multiple parts with ATOS Q

Learn how to scan multiple identical parts simultaneously using the ATOS Q and a rotation table. Simply choose the workflow assistant for scanning multiple parts and follow the software as it guides you through the scanning process. Since the rotation table is marked with reference points, you can start scanning straight away. Partitioning the parts and aligning top and bottom scans is done with just a few clicks.

Do you have any question on our 3D scanners? Contact us via support@HandsOnMetrology.com

How to eliminate plastic warpage in quality control

Annoyed about plastic warpage and how it makes quality control of unassembled parts difficult? In this video, Toon shows you how to solve this problem: with the De-warp function that can be found in the full version of ZEISS INSPECT . It puts scanned plastic parts into a virtually assembled state, allowing you to check their dimensions as if they were assembled.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to perform a digital assembly in GOM Inspect

How to 3D scan objects without reference points

How to 3D scan faster with an automated rotation table

How to get even more out of your ATOS Q

ATOS Q: How to measure big parts

Use the 3D scanner ATOS Q to scan a large part with the measuring volume MV500. Even if the object is bigger than the measuring volume, you can capture it easily using reference points and stitching scans to get a high quality result including small details.

ATOS Q: How to measure top and bottom of a part

In this video, Dokus measures a part from the top and the bottom side to create a digital twin. A fast and easy workflow with the 3D scanner ATOS Q, assisted by the automatic rotation table and ZEISS INSPECT. After measuring, simply combine and polygonize the data.

ATOS Q: Measure with the automatic rotation table

Learn how to use the automatic rotation table to speed up the 3D scanning workflow with ATOS Q. ZEISS INSPECT allows you to choose the number of automatic rotations. A rule of thumb: With 8 rotations you capture almost every aspect of the part.

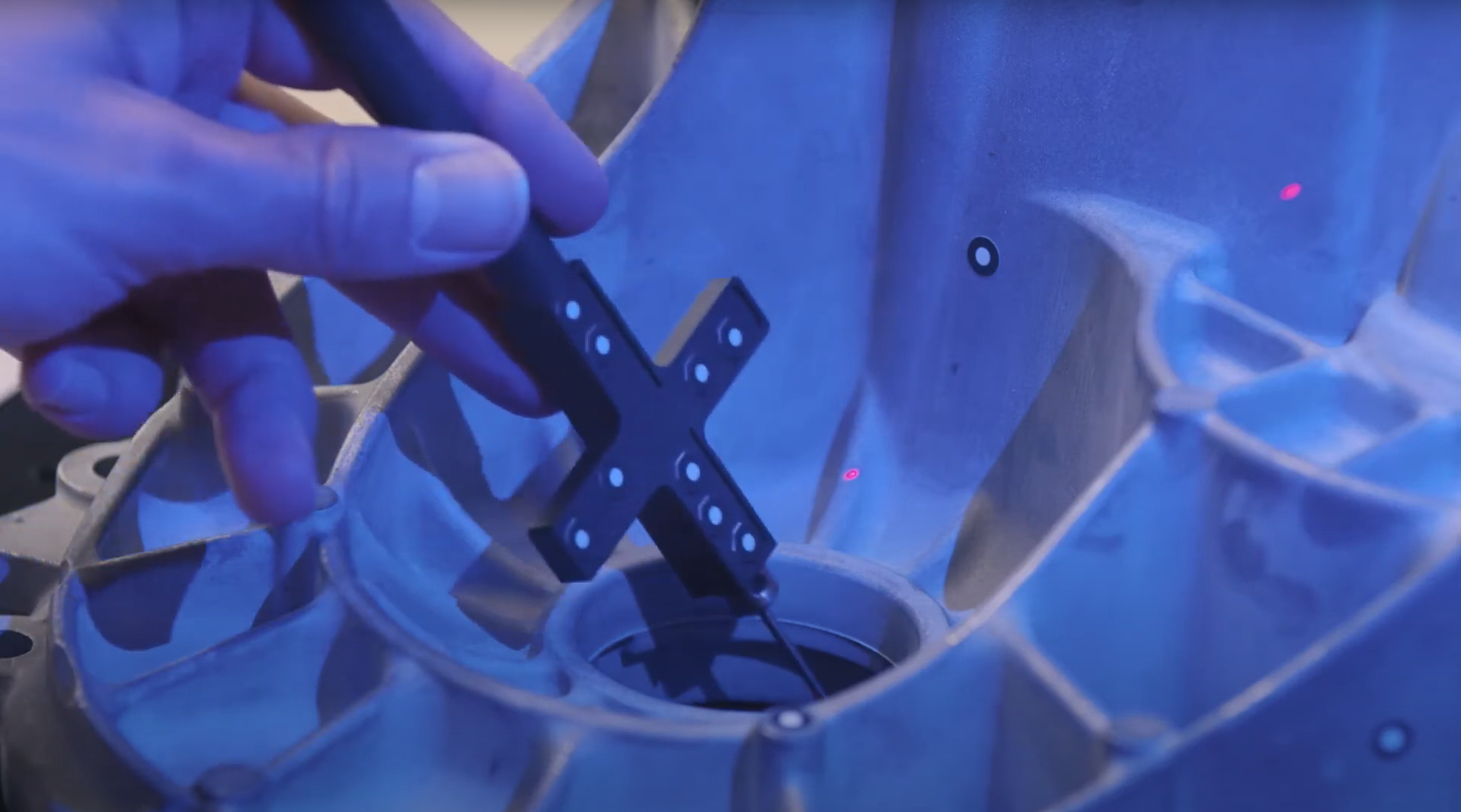

ATOS Q: Add single points with a touch probe

Learn how to use a touch probe to capture 3D data. Dokus shows you how to scan in difficult-to-reach areas and explains guided touch probe measurements in ZEISS INSPECT.

ATOS Q: Tips & tricks to scan even faster

Dokus gives valuable tips on using the 3D scanner ATOS Q. Learn how to measure the automatic exposure time and move the focus point, how to change into fast scan mode – if you don’t need details – or how to manually cut out points.

ATOS Q: Start a project in ZEISS INSPECT

Let Dokus show you how to make your first scan with ZEISS INSPECT. He takes you from the start screen to the checkered flag: a very detailed mesh. See different workspaces and scanning templates. Learn how to scan and watch what happens when you rotate the table.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

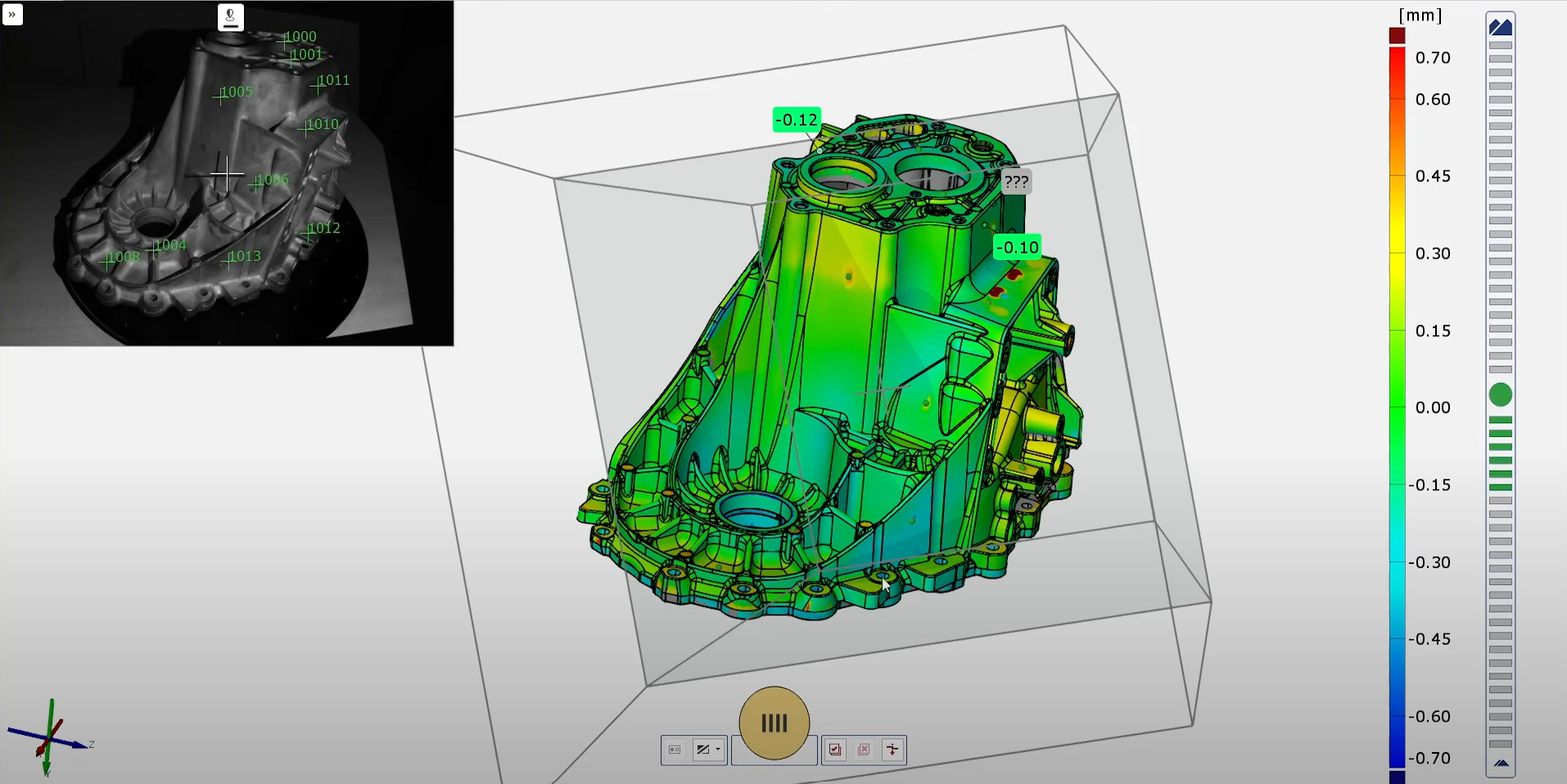

ATOS Q: Fast inspection with ZEISS INSPECT

Learn how to perform a fast inspection in ZEISS INSPECT by preparing a project in the inspection workspace, including the prealignment of a CAD file and a surface comparison. After the first scan, you can immediately look at the results.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

ATOS Q: Unboxing your new 3D scanner

Meet Dokus and the ATOS Q with its two cases. The first case contains the ATOS Q sensor and everything you might need on location, from rotation table to measuring volumes or the calibration plate. The second, smaller case contains the laptop and the mobile controller.

ATOS Q: How to set up the system

Watch Dokus set up the ATOS Q scanner and connect the sensor to the laptop. From opening up the mobile controller and mounting the sensor on the tripod to plugging in the licence key and connecting the automatic rotation table, he guides you step by step

ATOS Q: Change to a small measuring volume

If you need a high resolution for a small, detailed object, switching measuring volumes is easy with this 3D scanner. Dokus shows you step by step how to prepare and change the lenses, define the measuring volume in ZEISS INSPECT and calibrate the sensor.