Tactile measurements even under harsh conditions

A tactile solution for warm & dusty shop floors

Ready for your shop floor: This solution easily withstands temperatures up to 30°C and a humidity of 70%. Thermally stable hardware materials compensate the surrounding conditions and guarantee repeatable measurements every time. Another plus: Dust and dirt can’t harm your machine. Special guide covers protect ZEISS DuraMax with ZEISS INSPECT, making it a durable solution for nearly every work location.

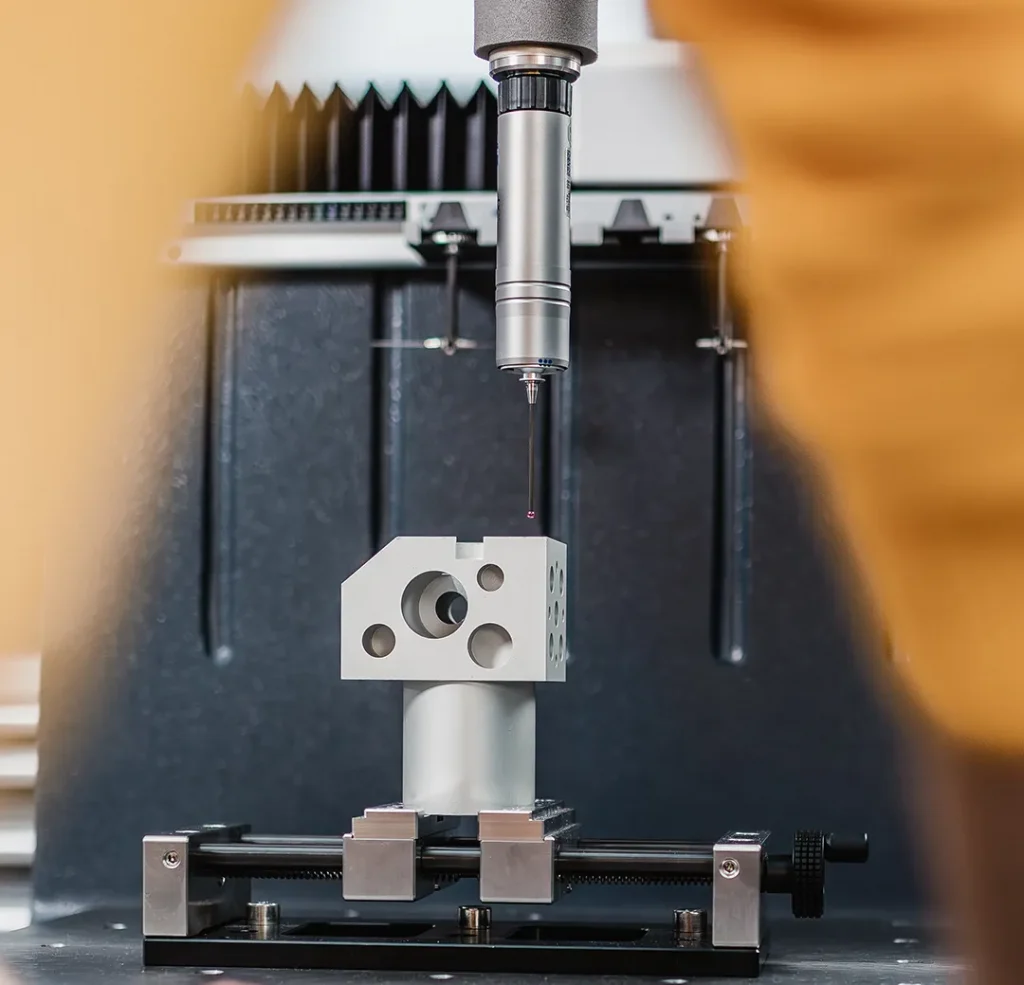

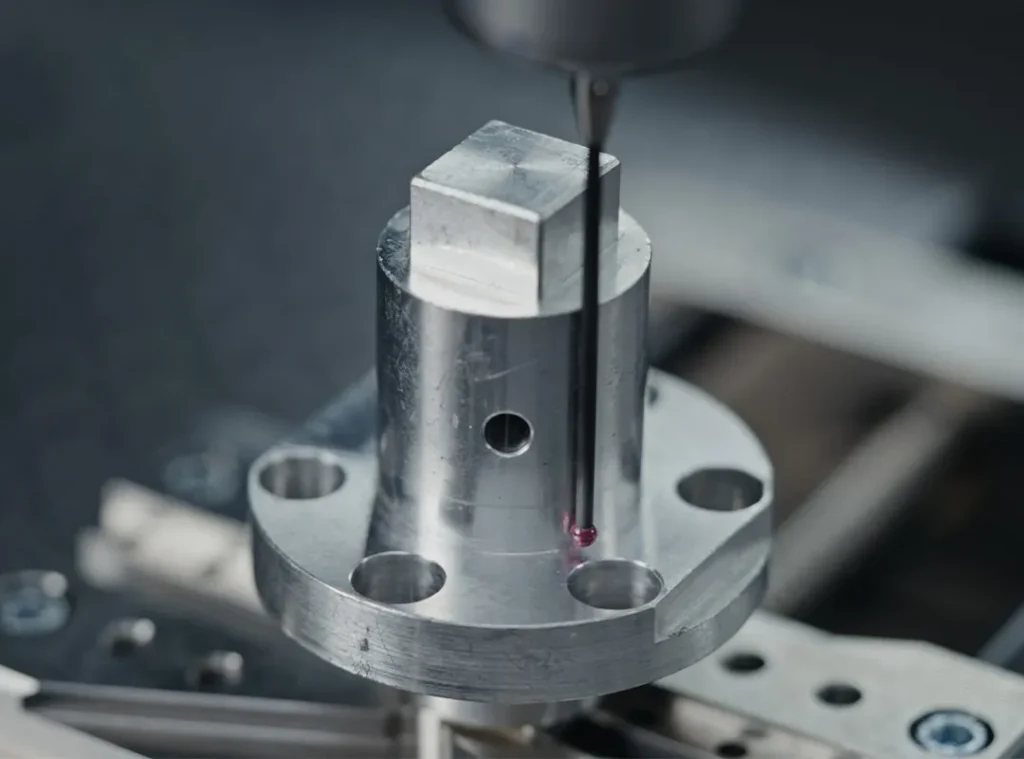

From production straight to inspection

Get ready to start your inspection immediately. Take your freshly manufactured part and measure it on the coordinate measuring machine. As hardly any preparation is necessary, you receive comprehensive measurement results in just a few moments.

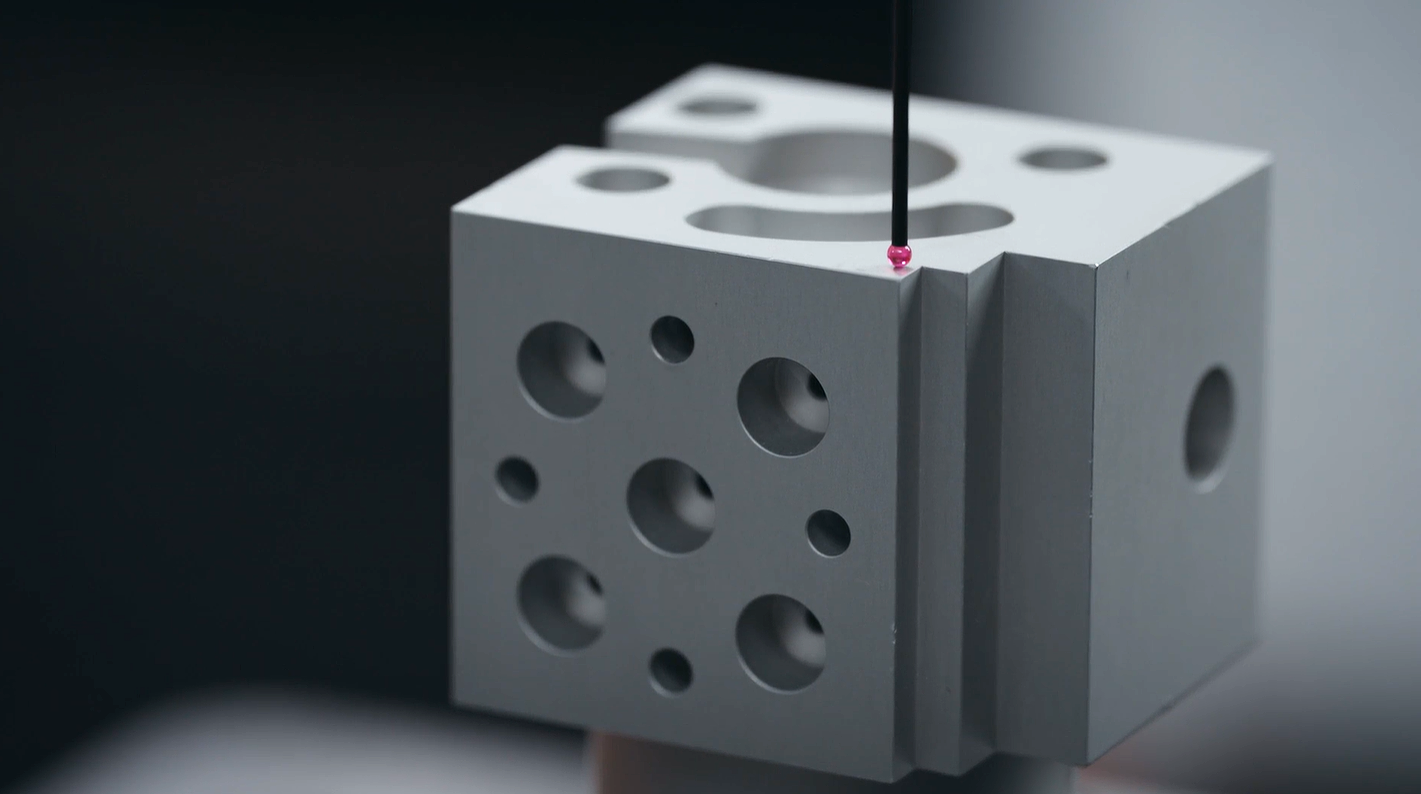

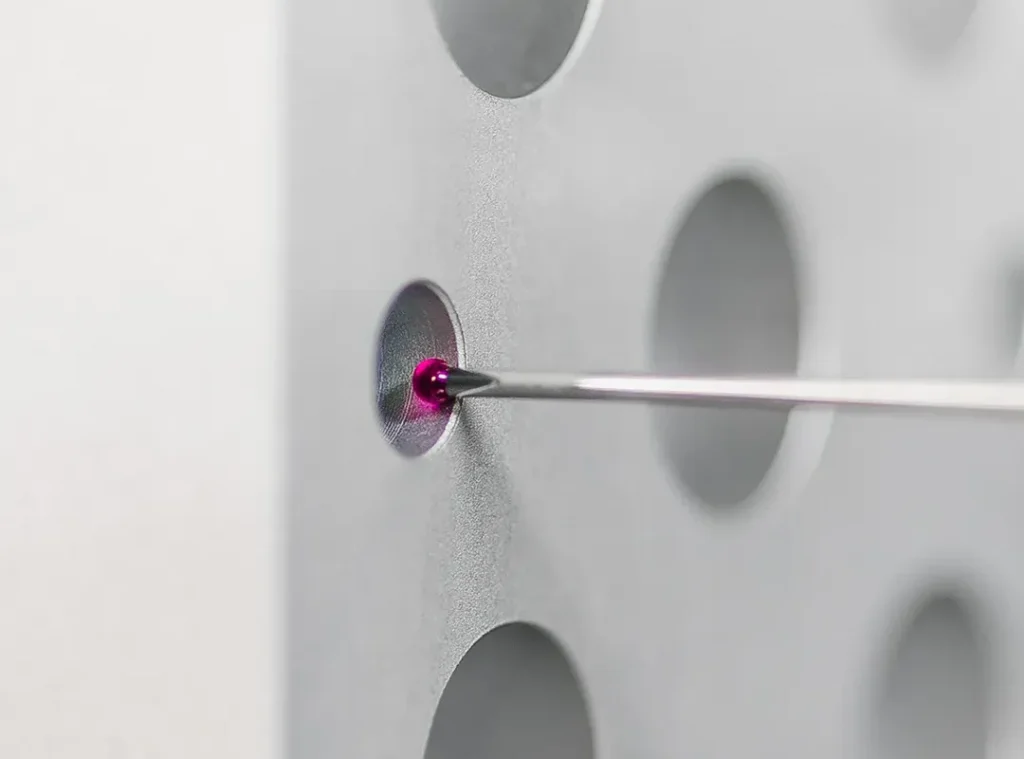

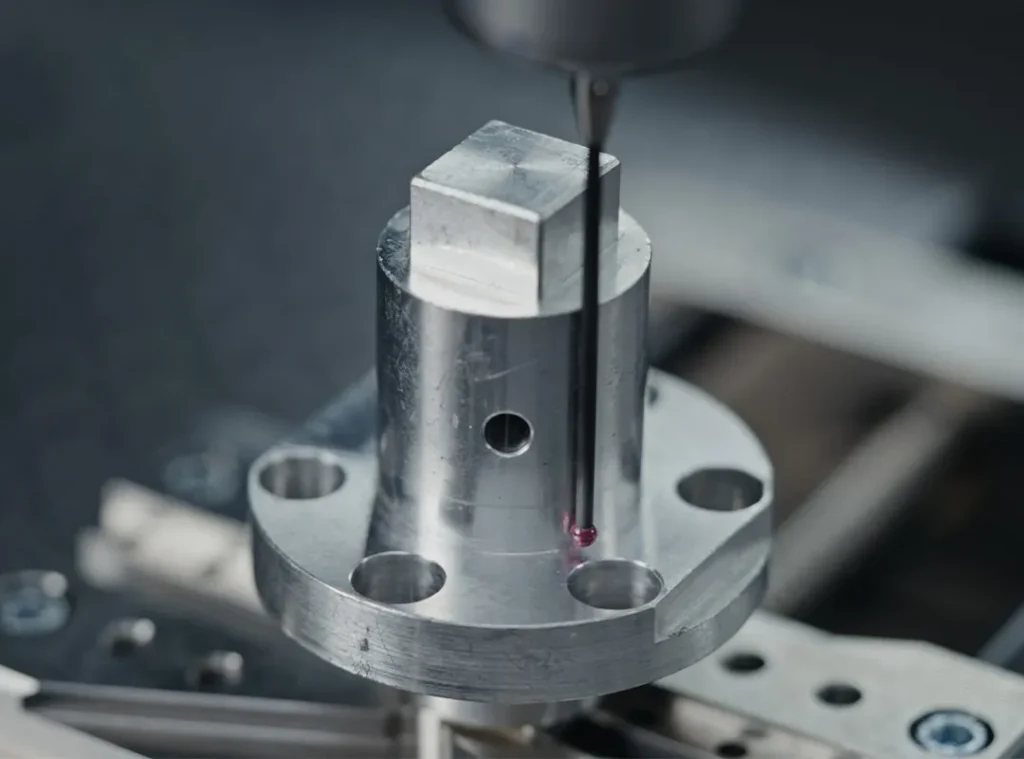

Made for small features

Precise data on the spot

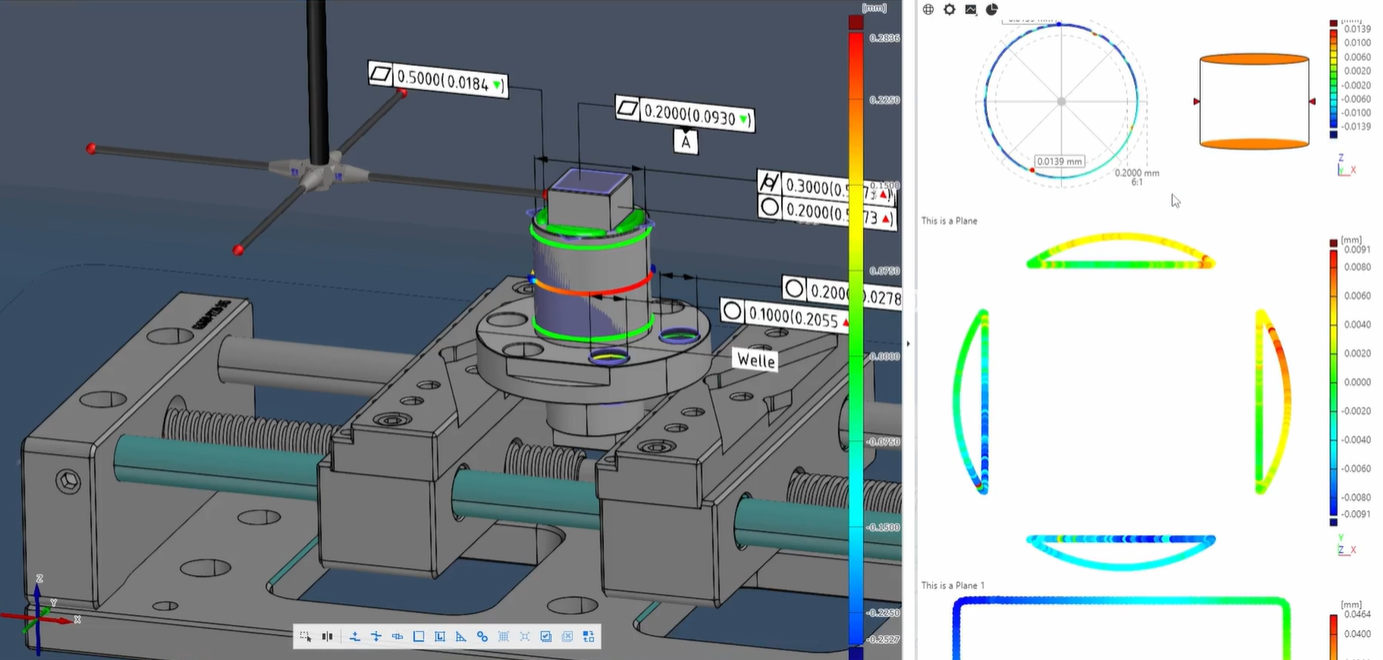

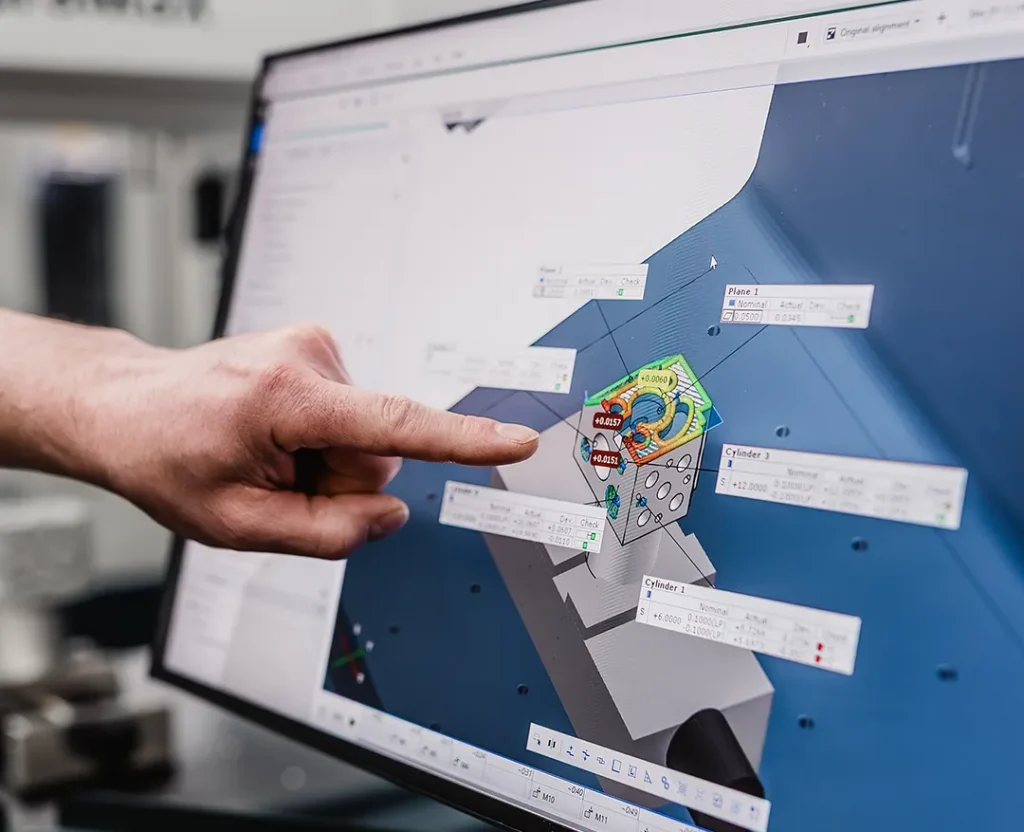

Operated with ZEISS INSPECT

Features

Increase your measurement speed

The ZEISS VAST XXT sensor of ZEISS DuraMax combines speed and precision. Single point measurements are carried out with the highest accuracy possible. For more complex tasks, the sensor even enables fast scanning of surfaces and contours. By measuring extremely high point densities, the evaluation of dimensions and geometries is as detailed as it can be.

Guided part programming

Ergonomic workflows

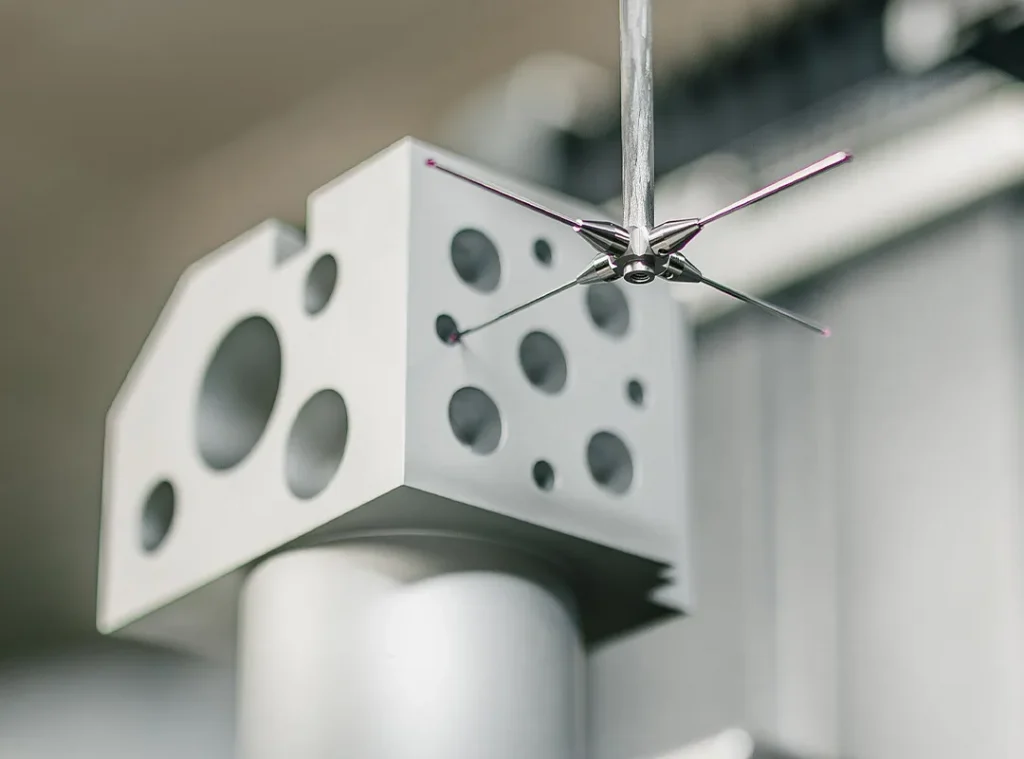

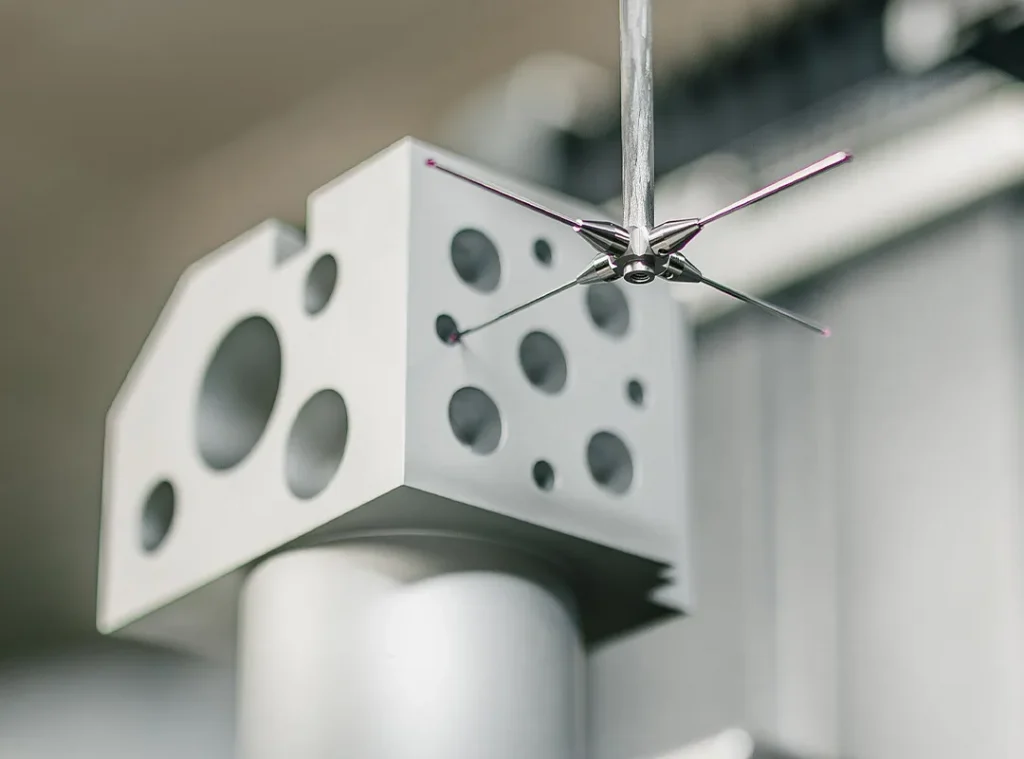

Automatic styli change

Small footprint, large impact

Despite its small footprint, this solution offers a large measuring volume for the inspection of various part sizes.

The small installation area allows you to focus on manufacturing high-quality products while keeping operating costs to a minimum.

Accessories

The right tools for your inspection

Configure your solution the way you need it. Choose between two base variants depending on the operating site. With two styli sets you easily adapt the measurement options to the respective measurement requirements. For an easy part switch or a large number of parts to be inspected, pallets are the perfect addition to your workflow.

A wide range of applications

Industries

- Medical/Pharmaceutical

- Aerospace

- Electronics

- Plastics industry

- Automotive

- Aftermarket

- Metal product manufacturing

Processes

- Milling

- Drilling

- Turning

- Grinding

- Additive manufacturing

- Injection molding

Materials

- Metals

- Ceramics

- Hard plastics

- Composites

Parts

- Housings

- CNC machined parts

- Shafts

Technical Data

ZEISS INSPECT

(ZEISS T VA 1) E0/E40 in μm

(ZEISS T VA 2) E0/E40 in μm

Do you want to find out more?

Discover more

i

Please select the topic you seek more information aboutDuraMax with ZEISS INSPECT: The basics of tactile measurement technology

Learn the basics of tactile measurement technology. Our CMM expert Florian gives an overview of tactile inspections and the features of our CMM ZEISS DuraMax with ZEISS INSEPCT.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

DuraMax with ZEISS INSPECT: The setup

You just got your CMM and directly want to start with your tactile inspection task? Watch this Getting Started to learn how to set up ZEISS DuraMax with ZEISS INSPECT for fast and accurate tactile inspections.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

DuraMax with ZEISS INSPECT: First use of ZEISS INSPECT

A software that offers easy operation of your CMM and simplifies the evaluation of tactile measurement data? In this Getting Started, Florian gives insights into ZEISS INSPECT software for CMMs and highlights important features, like the VMR.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

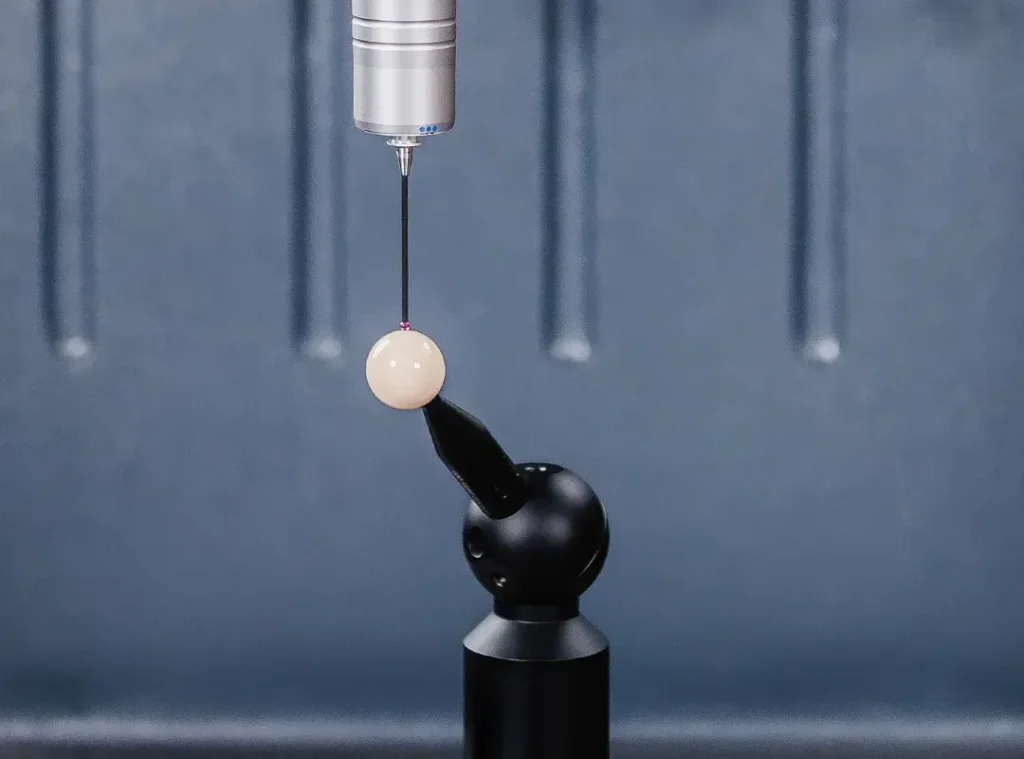

DuraMax with ZEISS INSPECT: Assemble and qualify stylus systems

Stylus systems are crucial for tactile data generation. Choosing the right styli for your tactile inspection and qualifying them properly have a major impact on the data quality. Learn here how to assemble and qualify your stylus systems for the CMM ZEISS DuraMax with ZEISS INSPECT.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

DuraMax with ZEISS INSPECT: Your first tactile measurement

Starting your first tactile inspection with ZEISS DuraMax with ZEISS INSPECT is easy. Watch this Getting Started to learn more about measurements with a CMM and recieve your precise tactile data in a matter of moments.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

DuraMax with ZEISS INSPECT: Complex part measurement

CMMs are made for inspecting complex geometries and small features at the highest accuracy possible. In this video you will learn the basics of complex parts measurements, including tips to simplify part programming.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com

DuraMax with ZEISS INSPECT: Reports for series measurements

Give more meaning to your tactile measurment data by professional reports. In this Getting Started, Florian shows you what ZEISS INSPECT software has to offer in terms of creating comprehensive resports and how to set up your reports for tactile series inspections with ZEISS DuraMax with ZEISS INSPECT.

Have you got any questions on metrology?

Contact us via support@HandsOnMetrology.com